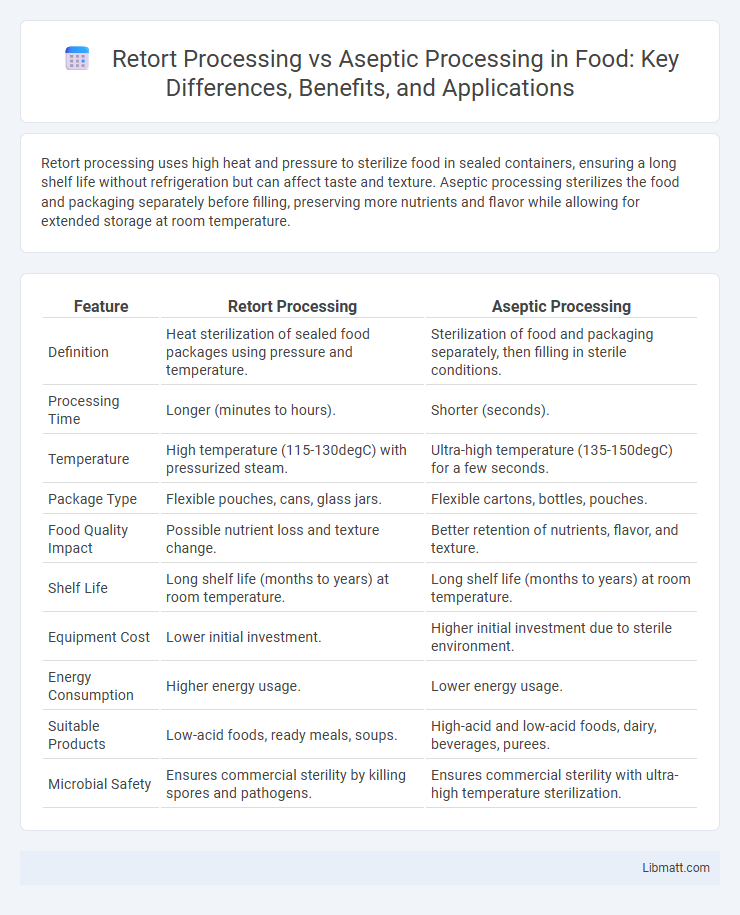

Retort processing uses high heat and pressure to sterilize food in sealed containers, ensuring a long shelf life without refrigeration but can affect taste and texture. Aseptic processing sterilizes the food and packaging separately before filling, preserving more nutrients and flavor while allowing for extended storage at room temperature.

Table of Comparison

| Feature | Retort Processing | Aseptic Processing |

|---|---|---|

| Definition | Heat sterilization of sealed food packages using pressure and temperature. | Sterilization of food and packaging separately, then filling in sterile conditions. |

| Processing Time | Longer (minutes to hours). | Shorter (seconds). |

| Temperature | High temperature (115-130degC) with pressurized steam. | Ultra-high temperature (135-150degC) for a few seconds. |

| Package Type | Flexible pouches, cans, glass jars. | Flexible cartons, bottles, pouches. |

| Food Quality Impact | Possible nutrient loss and texture change. | Better retention of nutrients, flavor, and texture. |

| Shelf Life | Long shelf life (months to years) at room temperature. | Long shelf life (months to years) at room temperature. |

| Equipment Cost | Lower initial investment. | Higher initial investment due to sterile environment. |

| Energy Consumption | Higher energy usage. | Lower energy usage. |

| Suitable Products | Low-acid foods, ready meals, soups. | High-acid and low-acid foods, dairy, beverages, purees. |

| Microbial Safety | Ensures commercial sterility by killing spores and pathogens. | Ensures commercial sterility with ultra-high temperature sterilization. |

Introduction to Thermal Food Processing Methods

Thermal food processing methods such as retort processing and aseptic processing are crucial for ensuring food safety and extending shelf life by eliminating harmful microorganisms. Retort processing uses high-temperature steam or water under pressure to sterilize food within sealed containers, suitable for low-acid foods. Aseptic processing involves sterilizing the food and packaging separately before filling in a sterile environment, enabling higher nutrient retention and fresher taste for your products.

Overview of Retort Processing

Retort processing involves heating packaged foods in sealed containers under high temperature and pressure to achieve commercial sterility, effectively eliminating microbial contaminants. This method is widely used for canned foods, offering a cost-effective and reliable way to extend shelf life without refrigeration. Retort processing ensures food safety by maintaining nutrient integrity while preventing spoilage through precise thermal treatment.

Understanding Aseptic Processing

Aseptic processing sterilizes both the product and packaging separately before filling in a sterile environment, ensuring superior product quality and extended shelf life without preservatives. Unlike retort processing, which uses high heat after packaging, aseptic processing better preserves taste, nutrients, and texture. You benefit from fresher-tasting products with enhanced safety and longer storage stability through aseptic techniques.

Key Differences Between Retort and Aseptic Processing

Retort processing involves thermal sterilization of filled containers using high-pressure steam at temperatures typically between 116degC and 130degC, ensuring extended shelf life while maintaining product safety. Aseptic processing sterilizes both the product and packaging separately before combining them in a sterile environment, allowing for higher nutrient retention and fresher taste without the need for refrigeration. The main differences lie in retort's in-package sterilization versus aseptic's pre-sterilized packaging, impacting product quality, processing time, and energy consumption.

Equipment and Technology Comparison

Retort processing utilizes high-temperature steam sterilization in pressure vessels equipped with rotating baskets or racks, relying on conventional heat transfer to ensure product safety and shelf stability. Aseptic processing employs advanced sterile filling lines combined with HEPA-filtered cleanrooms and UHT sterilization units, allowing for the packaging of sterilized products in sterile containers without further heat exposure. Your choice between these technologies hinges on the balance between equipment investment, production speed, and product quality requirements.

Impact on Food Quality and Shelf Life

Retort processing exposes food to high heat for extended periods, often diminishing nutrient content and altering texture, resulting in a shorter shelf life compared to aseptic processing. Aseptic processing sterilizes food and packaging separately before filling under sterile conditions, preserving a fresher taste, better nutrient retention, and extended shelf life up to six months or more without refrigeration. The choice between retort and aseptic methods significantly influences product quality, with aseptic processing offering superior preservation of vitamins, flavor, and texture while enhancing shelf stability.

Safety and Microbial Control Considerations

Retort processing utilizes high-temperature steam sterilization to achieve commercial sterility, effectively destroying resilient spores and pathogens, making it ideal for low-acid foods with extended shelf life. Aseptic processing sterilizes the product and packaging separately before filling under sterile conditions, reducing thermal exposure and preserving nutritional quality while maintaining microbial safety. Both methods ensure robust microbial control, but retort processing offers higher assurance against spore-forming bacteria, whereas aseptic processing demands stringent sterile environment maintenance to prevent contamination.

Packaging Requirements and Flexibility

Retort processing requires packaging materials that can withstand high heat and pressure, typically using flexible pouches or metal cans designed for thermal resistance, limiting packaging flexibility. Aseptic processing involves sterilizing the product and packaging separately, allowing the use of lightweight, non-metallic containers like cartons and plastic bottles, enhancing packaging versatility. The aseptic method enables more diverse shapes and sizes, while retort packaging is constrained by its need for durability during thermal sterilization.

Cost and Industrial Application Analysis

Retort processing involves higher energy consumption and extended processing times, leading to increased operational costs compared to aseptic processing, which uses continuous sterilization and packaging with lower energy input. Industrially, retort processing is favored for low-acid foods that require extended heat treatment for sterility, while aseptic processing excels in high-volume production of beverages and dairy products due to faster throughput and superior product quality retention. Cost efficiency in aseptic processing derives from reduced packaging material needs and minimized thermal damage, whereas retort processing demands robust packaging capable of withstanding high temperatures and pressures.

Choosing the Right Process for Your Product

Choosing between retort processing and aseptic processing depends on your product's heat sensitivity and shelf-life requirements. Retort processing uses high temperature and pressure to sterilize packaged products, ideal for low-acid foods but may affect texture and nutrients. Aseptic processing sterilizes the product and packaging separately, preserving quality and extending shelf life without refrigeration for sensitive items like dairy and juices.

retort processing vs aseptic processing Infographic

libmatt.com

libmatt.com