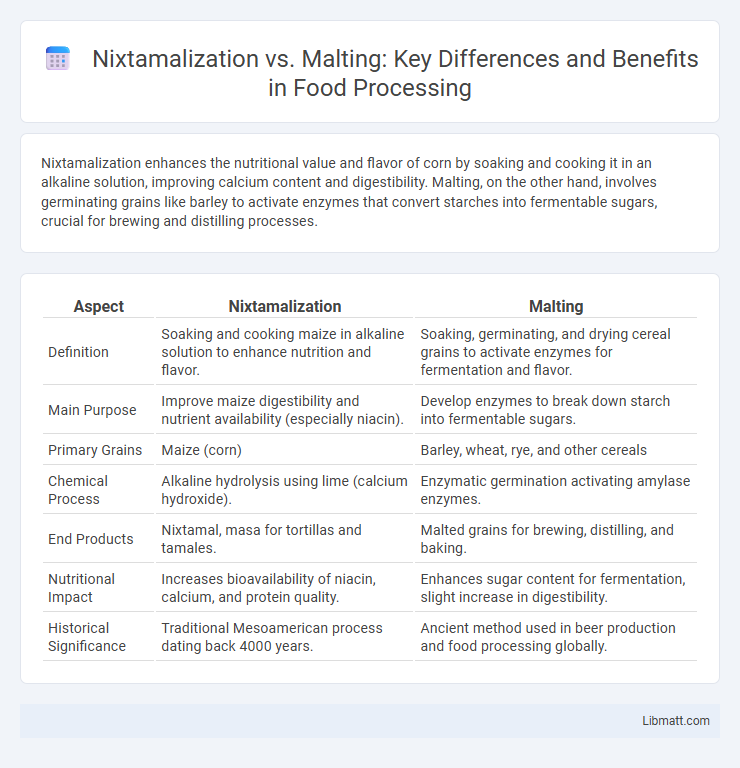

Nixtamalization enhances the nutritional value and flavor of corn by soaking and cooking it in an alkaline solution, improving calcium content and digestibility. Malting, on the other hand, involves germinating grains like barley to activate enzymes that convert starches into fermentable sugars, crucial for brewing and distilling processes.

Table of Comparison

| Aspect | Nixtamalization | Malting |

|---|---|---|

| Definition | Soaking and cooking maize in alkaline solution to enhance nutrition and flavor. | Soaking, germinating, and drying cereal grains to activate enzymes for fermentation and flavor. |

| Main Purpose | Improve maize digestibility and nutrient availability (especially niacin). | Develop enzymes to break down starch into fermentable sugars. |

| Primary Grains | Maize (corn) | Barley, wheat, rye, and other cereals |

| Chemical Process | Alkaline hydrolysis using lime (calcium hydroxide). | Enzymatic germination activating amylase enzymes. |

| End Products | Nixtamal, masa for tortillas and tamales. | Malted grains for brewing, distilling, and baking. |

| Nutritional Impact | Increases bioavailability of niacin, calcium, and protein quality. | Enhances sugar content for fermentation, slight increase in digestibility. |

| Historical Significance | Traditional Mesoamerican process dating back 4000 years. | Ancient method used in beer production and food processing globally. |

Understanding Nixtamalization: Definition and Process

Nixtamalization is a traditional process involving the soaking and cooking of maize in an alkaline solution, typically limewater, which enhances nutritional value and improves flavor and texture. This method increases bioavailability of niacin and reduces mycotoxins, making corn more digestible and beneficial. Your knowledge of nixtamalization's chemical transformation of corn contrasts with malting, where grains germinate to activate enzymes for fermentation or brewing.

Exploring Malting: Definition and Process

Malting is the controlled germination of cereal grains, primarily barley, which activates enzymes that convert starches into fermentable sugars essential for brewing and distilling. This process involves soaking the grains in water, allowing them to sprout, and then drying them to halt germination, producing malted grains rich in enzymes and flavor compounds. Understanding malting enhances your ability to optimize fermentation and develop distinct malt profiles in beverages.

Historical Origins of Nixtamalization and Malting

Nixtamalization originated over 3,000 years ago in Mesoamerica, where indigenous peoples developed the process to treat maize with alkaline solutions, enhancing its nutritional value and flavor. Malting dates back to ancient Mesopotamia and Egypt around 6,000 years ago, where early civilizations soaked and germinated grains like barley to produce fermentable sugars for brewing and baking. Understanding these historical origins highlights how your culinary techniques today are rooted in age-old agricultural innovations that transformed staple crops into essential food and beverage components.

Chemical Changes: Nixtamalization vs Malting

Nixtamalization induces chemical changes by soaking and cooking maize in an alkaline solution, which enhances niacin availability, reduces mycotoxins, and alters starch structure to improve digestibility. Malting triggers enzymatic activity during seed germination, converting starches into fermentable sugars and breaking down proteins and cell walls vital for brewing and food applications. The primary differentiation lies in nixtamalization's alkaline hydrolysis and malting's enzymatic hydrolysis, each driving distinct biochemical transformations in cereals.

Nutritional Benefits Compared

Nixtamalization enhances the bioavailability of niacin and increases calcium content by soaking and cooking maize in alkaline water, significantly improving its nutritional profile. Malting, involving the germination of grains, boosts the levels of vitamins B and C, enzymes, and antioxidants, which aid digestion and nutrient absorption. Your choice between these processes should consider specific dietary needs, as nixtamalization primarily improves mineral assimilation, while malting enriches enzymatic and vitamin content.

Impact on Flavor and Texture

Nixtamalization enhances flavor by developing a nutty, earthy taste and improving masa's homogeneity, resulting in a smoother texture ideal for tortillas and tamales. Malting induces enzymatic activity that converts starches into sugars, creating sweeter, more complex flavors and a tender, porous texture suitable for bread and beer production. The distinct biochemical processes in nixtamalization and malting create unique flavor profiles and textures catering to different culinary traditions.

Applications in Food and Beverage Production

Nixtamalization enhances the nutritional value and flavor of maize by soaking and cooking it in alkaline water, primarily used in producing tortillas, tamales, and masa-based products. Malting involves germinating cereal grains like barley to develop enzymes essential for fermenting beverages such as beer and whiskey, improving malt flavor and sugar content. Your choice between nixtamalization and malting depends on whether you aim to optimize corn-based food products or enhance fermentation processes in alcoholic beverage production.

Cultural Significance and Traditional Uses

Nixtamalization holds deep cultural significance in Mesoamerican cuisine, enhancing the nutritional value and flavor of maize for traditional dishes such as tortillas and tamales. Malting, a process rooted in ancient Mesopotamian and European cultures, is essential for brewing beer and producing malt-based foods, imparting unique sweetness and enzymes. Your appreciation of these techniques connects you to rich culinary traditions that have shaped food preparation for centuries.

Modern Innovations and Industrial Practices

Modern innovations in nixtamalization enhance efficiency by utilizing continuous flow systems and automated alkaline treatment, improving nutrient retention and reducing waste. Industrial malting incorporates precise temperature control, humidity regulation, and automated germination chambers to optimize enzyme development and uniformity in grain modification. Your food processing operations can benefit from integrating these advanced techniques to increase product quality and consistency.

Choosing the Right Method: Nixtamalization or Malting

Choosing between nixtamalization and malting depends on the desired nutritional and culinary outcomes; nixtamalization enhances calcium content and reduces mycotoxins in maize, making it ideal for tortillas and tamales. Malting, involving the controlled germination of grains, increases enzyme activity and sugar content for brewing and baking applications. Selecting the right method requires understanding the grain type and end product, as nixtamalization is suited for maize-based foods while malting benefits barley and other cereal grains for flavor and fermentable sugar development.

Nixtamalization vs Malting Infographic

libmatt.com

libmatt.com