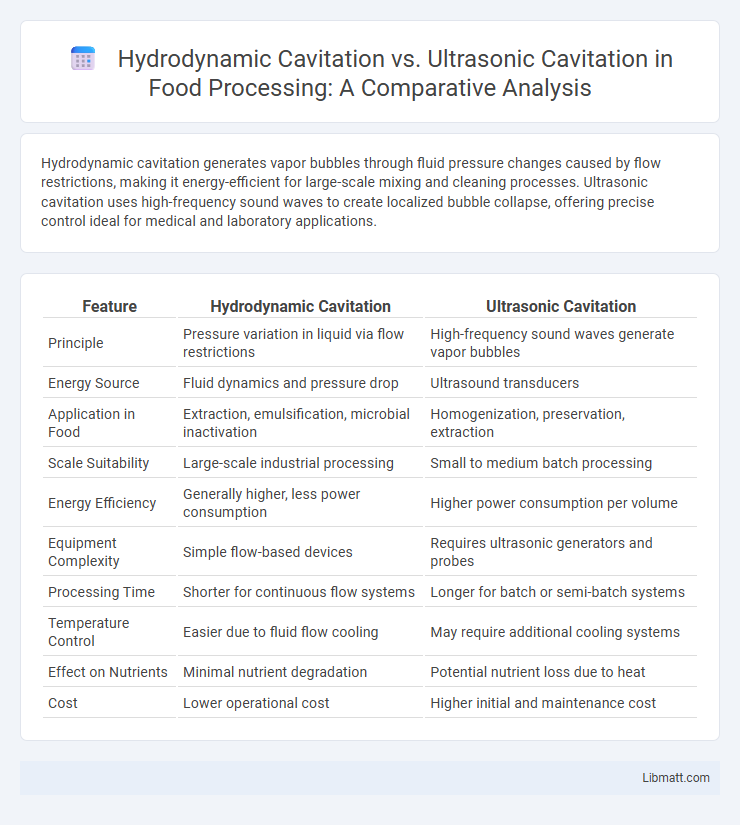

Hydrodynamic cavitation generates vapor bubbles through fluid pressure changes caused by flow restrictions, making it energy-efficient for large-scale mixing and cleaning processes. Ultrasonic cavitation uses high-frequency sound waves to create localized bubble collapse, offering precise control ideal for medical and laboratory applications.

Table of Comparison

| Feature | Hydrodynamic Cavitation | Ultrasonic Cavitation |

|---|---|---|

| Principle | Pressure variation in liquid via flow restrictions | High-frequency sound waves generate vapor bubbles |

| Energy Source | Fluid dynamics and pressure drop | Ultrasound transducers |

| Application in Food | Extraction, emulsification, microbial inactivation | Homogenization, preservation, extraction |

| Scale Suitability | Large-scale industrial processing | Small to medium batch processing |

| Energy Efficiency | Generally higher, less power consumption | Higher power consumption per volume |

| Equipment Complexity | Simple flow-based devices | Requires ultrasonic generators and probes |

| Processing Time | Shorter for continuous flow systems | Longer for batch or semi-batch systems |

| Temperature Control | Easier due to fluid flow cooling | May require additional cooling systems |

| Effect on Nutrients | Minimal nutrient degradation | Potential nutrient loss due to heat |

| Cost | Lower operational cost | Higher initial and maintenance cost |

Introduction to Cavitation Technologies

Hydrodynamic cavitation involves the formation of vapor bubbles in a liquid due to rapid pressure changes caused by fluid flow through a constriction, generating intense localized energy for applications in wastewater treatment, chemical processing, and food industry. Ultrasonic cavitation uses high-frequency sound waves (typically 20 kHz to 1 MHz) to produce microbubbles that collapse violently, delivering precise energy for medical therapies, cleaning processes, and material synthesis. Both technologies leverage cavitation effects but differ in energy source, operational mechanisms, and scalability for industrial applications.

Understanding Hydrodynamic Cavitation

Hydrodynamic cavitation occurs when fluid pressure drops below its vapor pressure, forming vapor bubbles that collapse violently, generating intense localized energy. This phenomenon is harnessed for applications such as wastewater treatment, enhancing chemical reactions, and improving emulsification processes. Understanding hydrodynamic cavitation involves analyzing factors like fluid velocity, pressure fluctuations, and geometric constrictions that influence cavitation intensity and bubble dynamics.

Exploring Ultrasonic Cavitation

Ultrasonic cavitation utilizes high-frequency sound waves, typically above 20 kHz, to generate microbubbles that collapse and produce intense local energy, enhancing processes like cleaning and sonochemistry. This method offers precise control over cavitation intensity and is effective for delicate materials where controlled agitation is required. Compared to hydrodynamic cavitation, ultrasonic cavitation enables targeted treatment with adjustable frequency and amplitude parameters, making it ideal for applications in pharmaceuticals, food processing, and wastewater treatment.

Mechanisms of Action: Hydrodynamic vs Ultrasonic

Hydrodynamic cavitation generates vapor bubbles through rapid pressure changes in fluid flow, causing bubble collapse that produces intense localized energy for cleaning or mixing applications. Ultrasonic cavitation relies on high-frequency sound waves to create microscopic bubbles that implode, releasing energy to disrupt particles or cells. Your choice between hydrodynamic and ultrasonic cavitation depends on specific process requirements, such as scale, energy efficiency, and target materials.

Energy Efficiency Comparison

Hydrodynamic cavitation typically offers higher energy efficiency compared to ultrasonic cavitation due to its lower power consumption and ease of scaling up for industrial applications. Ultrasonic cavitation relies on high-frequency sound waves that require substantial electrical input, often resulting in greater energy costs. You can achieve more sustainable and cost-effective processes by selecting hydrodynamic cavitation when energy efficiency is a critical factor.

Applications in Industry

Hydrodynamic cavitation is widely used in wastewater treatment, enhancing pollutant degradation and biofuel production due to its efficient energy consumption and scalability. Ultrasonic cavitation finds extensive applications in precision cleaning, emulsification, and pharmaceutical manufacturing by generating localized intense shear forces. Your choice between these methods depends on the specific industrial process requirements, such as energy efficiency, scale, and precision.

Scale-Up Potential and Practical Limitations

Hydrodynamic cavitation offers greater scale-up potential due to its ability to process large volumes of fluid with lower energy consumption and simpler reactor designs, making it suitable for industrial applications. Ultrasonic cavitation, while effective at lab and pilot scales for precise treatment, faces practical limitations such as high energy costs, equipment wear, and challenges in uniform cavitation distribution during scale-up. The choice between hydrodynamic and ultrasonic cavitation hinges on balancing operational efficiency and scalability against specific process requirements and economic constraints.

Environmental Impact and Safety

Hydrodynamic cavitation generates fewer harmful byproducts compared to ultrasonic cavitation, making it a more environmentally friendly option due to lower energy consumption and reduced chemical waste. Ultrasonic cavitation, while effective for precise applications, can cause localized heating and noise pollution, posing safety concerns for operators. Both methods require careful management, but hydrodynamic cavitation's scalable and less intrusive process offers enhanced environmental safety benefits.

Cost Analysis and Maintenance

Hydrodynamic cavitation systems generally have lower operational costs and simpler maintenance requirements due to fewer moving parts and reduced energy consumption compared to ultrasonic cavitation devices. Ultrasonic cavitation typically demands higher initial investment and ongoing maintenance, including transducer replacement and calibration, which can increase overall expenses. You should consider hydrodynamic cavitation if minimizing cost and maintenance complexity is a priority for your application.

Future Trends in Cavitation Technologies

Future trends in cavitation technologies emphasize enhanced energy efficiency and scalability in hydrodynamic cavitation systems for industrial wastewater treatment and biofuel production. Ultrasonic cavitation advances focus on precise control of cavitation bubble dynamics through frequency modulation to improve applications in medical therapy and nanomaterial synthesis. Integration of AI-driven monitoring and adaptive control systems is expected to optimize cavitation intensity and yield, driving innovation across environmental and pharmaceutical sectors.

hydrodynamic cavitation vs ultrasonic cavitation Infographic

libmatt.com

libmatt.com