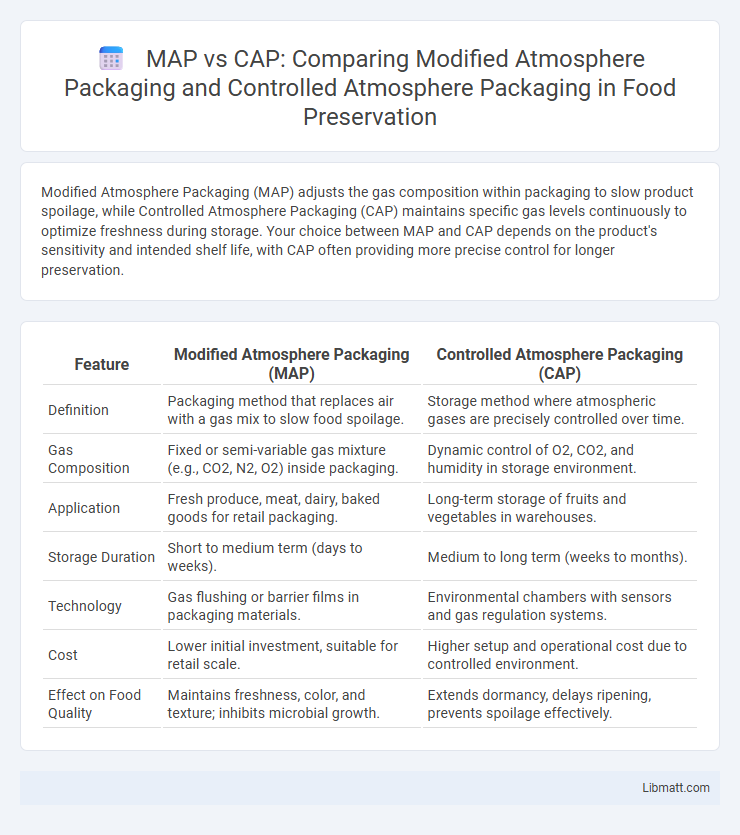

Modified Atmosphere Packaging (MAP) adjusts the gas composition within packaging to slow product spoilage, while Controlled Atmosphere Packaging (CAP) maintains specific gas levels continuously to optimize freshness during storage. Your choice between MAP and CAP depends on the product's sensitivity and intended shelf life, with CAP often providing more precise control for longer preservation.

Table of Comparison

| Feature | Modified Atmosphere Packaging (MAP) | Controlled Atmosphere Packaging (CAP) |

|---|---|---|

| Definition | Packaging method that replaces air with a gas mix to slow food spoilage. | Storage method where atmospheric gases are precisely controlled over time. |

| Gas Composition | Fixed or semi-variable gas mixture (e.g., CO2, N2, O2) inside packaging. | Dynamic control of O2, CO2, and humidity in storage environment. |

| Application | Fresh produce, meat, dairy, baked goods for retail packaging. | Long-term storage of fruits and vegetables in warehouses. |

| Storage Duration | Short to medium term (days to weeks). | Medium to long term (weeks to months). |

| Technology | Gas flushing or barrier films in packaging materials. | Environmental chambers with sensors and gas regulation systems. |

| Cost | Lower initial investment, suitable for retail scale. | Higher setup and operational cost due to controlled environment. |

| Effect on Food Quality | Maintains freshness, color, and texture; inhibits microbial growth. | Extends dormancy, delays ripening, prevents spoilage effectively. |

Introduction to MAP and CAP

Modified Atmosphere Packaging (MAP) alters the gas composition surrounding perishable products, typically increasing levels of carbon dioxide and nitrogen to extend shelf life by slowing microbial growth and respiration rates. Controlled Atmosphere Packaging (CAP) maintains precise gas concentrations and environmental conditions, often including temperature and humidity control, to optimize product preservation beyond standard MAP techniques. Both technologies aim to reduce spoilage and maintain quality but CAP provides a more rigorous and tightly regulated environment for highly sensitive produce or long-term storage.

Definition of Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) refers to a technology that alters the composition of the internal atmosphere of a package to extend the shelf life of food products, primarily by reducing oxygen levels and increasing carbon dioxide or nitrogen. This technique slows down microbial growth and oxidation processes, preserving freshness, flavor, and texture of perishable items such as fruits, vegetables, and meats. MAP is widely used in the food industry to maintain quality while reducing spoilage during storage and transportation.

Definition of Controlled Atmosphere Packaging (CAP)

Controlled Atmosphere Packaging (CAP) is a preservation technique that precisely regulates oxygen, carbon dioxide, and nitrogen levels within storage environments to extend the shelf life of perishable products such as fruits and vegetables. Unlike Modified Atmosphere Packaging (MAP), which adjusts the gas composition passively inside sealed packages, CAP actively monitors and adjusts the atmosphere in storage rooms or containers. Understanding Controlled Atmosphere Packaging helps optimize your product freshness and maintain quality during long-term storage.

Key Differences Between MAP and CAP

Modified Atmosphere Packaging (MAP) involves altering the gas composition inside packaging to extend product shelf life, primarily using a mix of oxygen, carbon dioxide, and nitrogen. Controlled Atmosphere Packaging (CAP) goes further by continuously monitoring and adjusting gas levels, humidity, and temperature to maintain optimal storage conditions. Your choice depends on the level of control required, with CAP offering precise environmental regulation compared to the static atmosphere in MAP.

Applications of MAP in the Food Industry

Modified Atmosphere Packaging (MAP) is widely used in the food industry to extend the shelf life of fresh produce, meat, seafood, and bakery products by altering the gas composition surrounding the food to reduce oxidation and microbial growth. Common MAP gases include oxygen, carbon dioxide, and nitrogen, tailored to specific food types to maintain freshness and quality during storage and transportation. This technology enhances product safety, reduces food waste, and supports global supply chains by enabling longer distribution periods without compromising sensory attributes.

Applications of CAP in Food Storage and Transport

Controlled Atmosphere Packaging (CAP) is extensively used in storing and transporting fresh produce such as apples, pears, and berries to extend shelf life by precisely regulating oxygen, carbon dioxide, and humidity levels. This technology slows down the respiration rate and delays ripening, maintaining quality and freshness during long-distance shipping. Your supply chain benefits from reduced spoilage and optimized storage conditions, ensuring fruits and vegetables reach consumers in optimal condition.

Advantages of Modified Atmosphere Packaging

Modified Atmosphere Packaging (MAP) extends the shelf life of perishable foods by altering the gas composition around the product, primarily reducing oxygen and increasing carbon dioxide or nitrogen levels to slow microbial growth and oxidation. Your fresh produce, meat, or seafood retain their quality, color, and flavor longer without the need for preservatives, making MAP ideal for retail display and storage. The flexibility and cost-effectiveness of MAP compared to Controlled Atmosphere Packaging (CAP) offer manufacturers scalable solutions with simpler technology and lower operational requirements.

Advantages of Controlled Atmosphere Packaging

Controlled Atmosphere Packaging (CAP) offers superior gas composition control by continuously adjusting oxygen, carbon dioxide, and nitrogen levels to extend produce shelf life and maintain quality more effectively than Modified Atmosphere Packaging (MAP). CAP reduces respiration rates and delays ripening and spoilage in fruits and vegetables, preserving freshness and nutritional value for longer periods during storage and transportation. Enhanced flexibility in gas regulation with CAP minimizes post-harvest losses and improves overall supply chain efficiency in the fresh produce industry.

Challenges and Limitations of MAP and CAP

Modified Atmosphere Packaging (MAP) faces challenges such as maintaining optimal gas compositions throughout storage since gas permeability of packaging materials can vary, potentially leading to reduced product shelf life or spoilage. Controlled Atmosphere Packaging (CAP) requires precise and continuous monitoring of oxygen, carbon dioxide, and nitrogen levels, demanding costly technology and infrastructure that may limit its widespread adoption. Both MAP and CAP struggle with adapting to diverse product types and varying respiration rates, which can complicate achieving the ideal atmosphere for preserving freshness and quality.

Choosing Between MAP and CAP: Which Is Best?

Choosing between Modified Atmosphere Packaging (MAP) and Controlled Atmosphere Packaging (CAP) depends on the specific perishability and storage duration of your products. MAP adjusts the gas composition inside the package at the time of sealing, ideal for short-term freshness, while CAP continuously regulates oxygen, carbon dioxide, and humidity levels in storage environments for longer shelf life. Understanding these differences helps maximize product quality and reduce spoilage based on your supply chain needs.

MAP vs CAP (modified atmosphere packaging vs controlled atmosphere packaging) Infographic

libmatt.com

libmatt.com