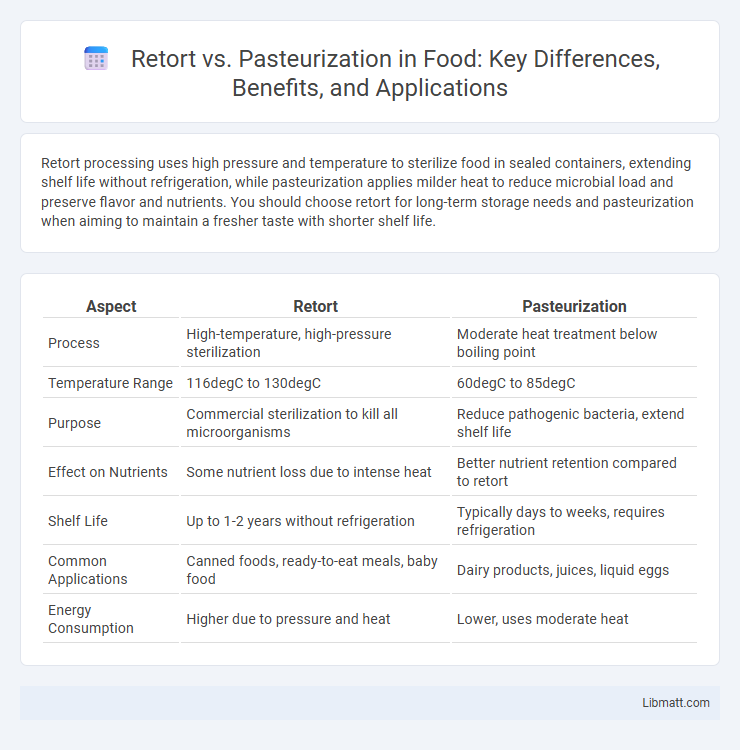

Retort processing uses high pressure and temperature to sterilize food in sealed containers, extending shelf life without refrigeration, while pasteurization applies milder heat to reduce microbial load and preserve flavor and nutrients. You should choose retort for long-term storage needs and pasteurization when aiming to maintain a fresher taste with shorter shelf life.

Table of Comparison

| Aspect | Retort | Pasteurization |

|---|---|---|

| Process | High-temperature, high-pressure sterilization | Moderate heat treatment below boiling point |

| Temperature Range | 116degC to 130degC | 60degC to 85degC |

| Purpose | Commercial sterilization to kill all microorganisms | Reduce pathogenic bacteria, extend shelf life |

| Effect on Nutrients | Some nutrient loss due to intense heat | Better nutrient retention compared to retort |

| Shelf Life | Up to 1-2 years without refrigeration | Typically days to weeks, requires refrigeration |

| Common Applications | Canned foods, ready-to-eat meals, baby food | Dairy products, juices, liquid eggs |

| Energy Consumption | Higher due to pressure and heat | Lower, uses moderate heat |

Introduction to Retort and Pasteurization

Retort and pasteurization are thermal processing methods used to ensure food safety and extend shelf life by eliminating harmful microorganisms. Retort involves high-temperature sterilization in sealed containers, effectively killing spores and enzymes, suitable for low-acid foods like canned vegetables and meats. Pasteurization uses lower temperatures over shorter times, primarily targeting pathogenic bacteria in products such as milk and juices, preserving nutritional qualities and flavor.

Defining Retort Processing

Retort processing is a thermal sterilization method that uses high temperature and pressure to achieve commercial sterility in food products, extending shelf life without refrigeration. This technique involves placing sealed containers in a retort chamber where they are subjected to temperatures typically between 116degC and 130degC for a specific time to eliminate microbial pathogens. Unlike pasteurization, which uses lower temperatures to reduce microbial load, retort processing ensures complete sterilization suitable for low-acid foods requiring long-term storage.

What is Pasteurization?

Pasteurization is a heat treatment process that aims to kill harmful microorganisms in food and beverages without compromising their nutritional value or taste. This method typically involves heating products like milk, juice, or eggs to a specific temperature for a set period, effectively extending shelf life and ensuring safety. You can rely on pasteurization to reduce the risk of foodborne illnesses while maintaining freshness and quality.

Key Differences Between Retort and Pasteurization

Retort processing uses high temperature and pressure to sterilize food, achieving commercial sterility and enabling long shelf life without refrigeration, unlike pasteurization, which applies moderate heat to reduce microbial load and extend shelf life for refrigerated products. Retort is ideal for low-acid foods like canned vegetables and meats, while pasteurization is commonly used for dairy, juices, and liquid eggs to retain more nutrients and flavor. The primary difference lies in retort's ability to eliminate spores through sterilization, whereas pasteurization only targets vegetative bacteria, requiring subsequent refrigeration for safety.

Advantages of Retort Technology

Retort technology offers superior sterilization capabilities by subjecting products to higher temperatures and pressures, extending shelf life without preservatives. This method ensures enhanced microbial safety and maintains product quality for long-term storage, making it ideal for ready-to-eat meals and canned goods. Your food benefits from nutrient retention and flavor preservation compared to conventional pasteurization techniques.

Benefits of Pasteurization Methods

Pasteurization methods effectively reduce harmful pathogens in food and beverages, enhancing safety and extending shelf life without significant nutrient loss. The process maintains flavor and texture better than retort sterilization, which uses higher temperatures that can alter product quality. Pasteurization also supports energy efficiency and cost-effectiveness in large-scale food processing operations.

Common Applications of Retort vs Pasteurization

Retort processing is commonly used for sterilizing canned and shelf-stable foods such as soups, vegetables, and ready-to-eat meals, ensuring extended shelf life without refrigeration. Pasteurization is typically applied to liquid products like milk, juices, and dairy-based beverages to reduce microbial load while preserving flavor and nutritional quality. Industrial retort systems are favored for high-acid and low-acid canned goods, whereas pasteurization is essential for products requiring milder heat treatment to maintain freshness.

Food Safety and Shelf-Life Comparison

Retort processing uses high-temperature sterilization to eliminate all microorganisms, ensuring longer shelf life and superior food safety compared to pasteurization, which only reduces pathogenic bacteria through moderate heat. Pasteurized foods typically require refrigeration and have shorter shelf lives, while retorted foods are shelf-stable for months or even years without refrigeration. Your choice between retort and pasteurization affects food safety levels and storage duration based on the desired product quality and distribution needs.

Quality and Nutritional Impact

Retort processing subjects food to higher temperatures for longer durations, which can lead to greater nutrient degradation and changes in texture and flavor compared to pasteurization. Pasteurization uses milder heat treatments, preserving more vitamins, antioxidants, and natural flavors while ensuring microbial safety. Consequently, pasteurized products generally retain better nutritional quality and sensory attributes than those treated by retort methods.

Choosing the Right Process for Your Product

Selecting the appropriate thermal processing method depends on product type, shelf life requirements, and nutritional goals. Retort processing uses high temperature and pressure to achieve commercial sterility, ideal for ready-to-eat meals and shelf-stable products with extended shelf life. Pasteurization employs milder heat treatment targeting pathogenic bacteria, preserving more nutrients and flavor, suitable for beverages and perishable items requiring refrigeration.

Retort vs Pasteurization Infographic

libmatt.com

libmatt.com