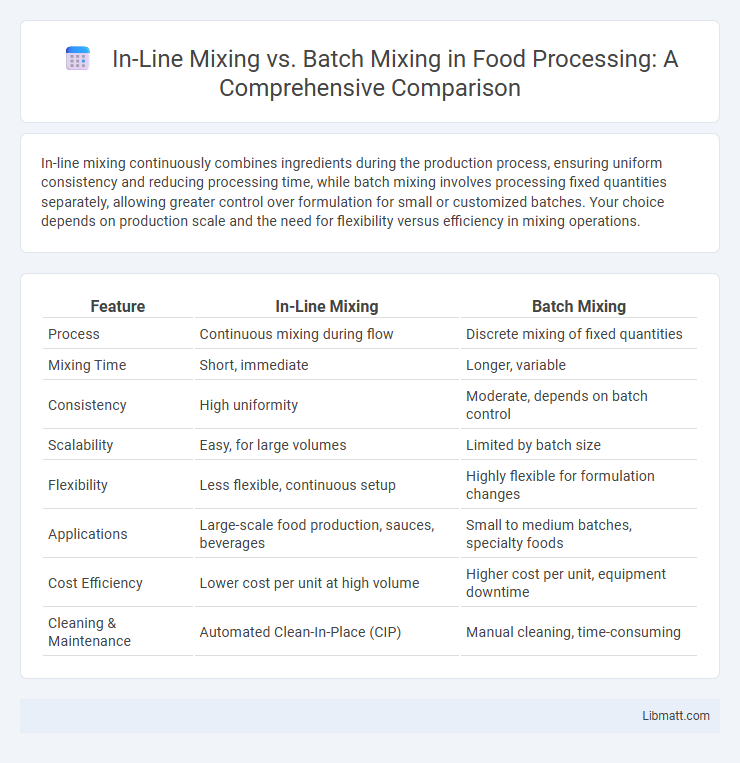

In-line mixing continuously combines ingredients during the production process, ensuring uniform consistency and reducing processing time, while batch mixing involves processing fixed quantities separately, allowing greater control over formulation for small or customized batches. Your choice depends on production scale and the need for flexibility versus efficiency in mixing operations.

Table of Comparison

| Feature | In-Line Mixing | Batch Mixing |

|---|---|---|

| Process | Continuous mixing during flow | Discrete mixing of fixed quantities |

| Mixing Time | Short, immediate | Longer, variable |

| Consistency | High uniformity | Moderate, depends on batch control |

| Scalability | Easy, for large volumes | Limited by batch size |

| Flexibility | Less flexible, continuous setup | Highly flexible for formulation changes |

| Applications | Large-scale food production, sauces, beverages | Small to medium batches, specialty foods |

| Cost Efficiency | Lower cost per unit at high volume | Higher cost per unit, equipment downtime |

| Cleaning & Maintenance | Automated Clean-In-Place (CIP) | Manual cleaning, time-consuming |

Introduction to Mixing Technologies

In-line mixing technology continuously blends ingredients as they flow through a pipeline, ensuring consistent product uniformity and efficient process integration in various industries. Batch mixing involves combining materials in fixed quantities within a confined vessel, allowing precise control over formulation adjustments and quality checks. Your choice between in-line and batch mixing depends on production volume, product consistency requirements, and operational flexibility.

Defining In-Line Mixing

In-line mixing is a continuous process where ingredients are combined and homogenized directly within the production line, ensuring consistent product quality and reduced processing time. This method uses specialized equipment such as static mixers or high-shear in-line mixers to achieve rapid and uniform blending without the need for intermediate storage. Its efficiency and ability to maintain product integrity make it ideal for industries like pharmaceuticals, food and beverage, and chemicals.

Understanding Batch Mixing

Batch mixing involves combining ingredients in a single container to produce a specific quantity of product before moving to the next batch. This method allows precise control over formulation, consistency, and quality for small to medium production volumes. Batch mixing is ideal for recipes requiring exact ingredient ratios and flexibility in production scheduling.

Key Differences Between In-Line and Batch Mixing

In-line mixing offers continuous processing by blending materials directly within the production line, optimizing efficiency and reducing material waste, while batch mixing processes discrete quantities in separate vessels, allowing greater control over small production runs. In-line mixing ensures consistent product quality through real-time adjustments and homogeneity, whereas batch mixing provides flexibility for varied formulations but may result in longer downtime between batches. Your choice between in-line and batch mixing depends on production scale, consistency requirements, and process integration needs.

Efficiency and Processing Time Comparison

In-line mixing significantly enhances efficiency and reduces processing time by continuously blending ingredients as they flow through the system, eliminating the need for separate batch preparation. Batch mixing requires longer cycles for loading, mixing, and unloading, which reduces overall throughput and increases labor costs. Your production line can achieve faster turnaround and more consistent product quality with in-line mixing, streamlining operations and minimizing downtime.

Product Consistency and Quality Control

In-line mixing offers superior product consistency by continuously blending ingredients in real-time, minimizing variations caused by batch-to-batch differences common in batch mixing processes. Advanced sensors and automated quality control systems integrated into in-line mixers enable precise monitoring and immediate adjustments, ensuring uniformity and reducing the risk of contamination. Batch mixing, while flexible for small-scale production, often requires extensive sampling and testing to maintain quality control, which can lead to delays and inconsistencies in the final product.

Scalability for Industrial Applications

In-line mixing offers superior scalability for industrial applications by enabling continuous processing, reducing downtime, and ensuring consistent product quality across large volumes. Batch mixing, while versatile for smaller or varied production runs, often faces limitations in scalability due to longer cycle times and potential inconsistencies between batches. Your choice should consider the production volume and the need for uniformity when scaling up operations.

Energy Consumption and Cost Implications

In-line mixing systems typically consume less energy than batch mixing due to continuous processing and reduced idle time, leading to significant operational cost savings. Batch mixing often requires higher energy inputs for heating, agitation, and cleaning cycles between batches, increasing overall production expenses. Choosing in-line mixing can optimize both energy efficiency and cost-effectiveness, particularly in large-scale manufacturing environments.

Maintenance and Operational Considerations

In-line mixing systems require less frequent maintenance due to continuous flow processes that reduce the risk of residue buildup, whereas batch mixing demands thorough cleaning between cycles, increasing downtime. Operational considerations favor in-line mixers for consistent product quality and reduced labor costs, while batch mixing offers more flexibility for small-scale or varied production runs. Your choice between the two should balance maintenance efficiency with production volume and product consistency requirements.

Selecting the Right Mixing Method for Your Process

Selecting the right mixing method depends on factors such as production scale, consistency requirements, and equipment capabilities. In-line mixing offers continuous processing with precise control, ideal for high-volume, homogenous blends, while batch mixing provides flexibility and simplicity suitable for small-scale or varied formulations. Evaluating process parameters like viscosity, shear sensitivity, and cleaning protocols ensures optimal selection between in-line and batch mixing for your specific application.

In-Line Mixing vs Batch Mixing Infographic

libmatt.com

libmatt.com