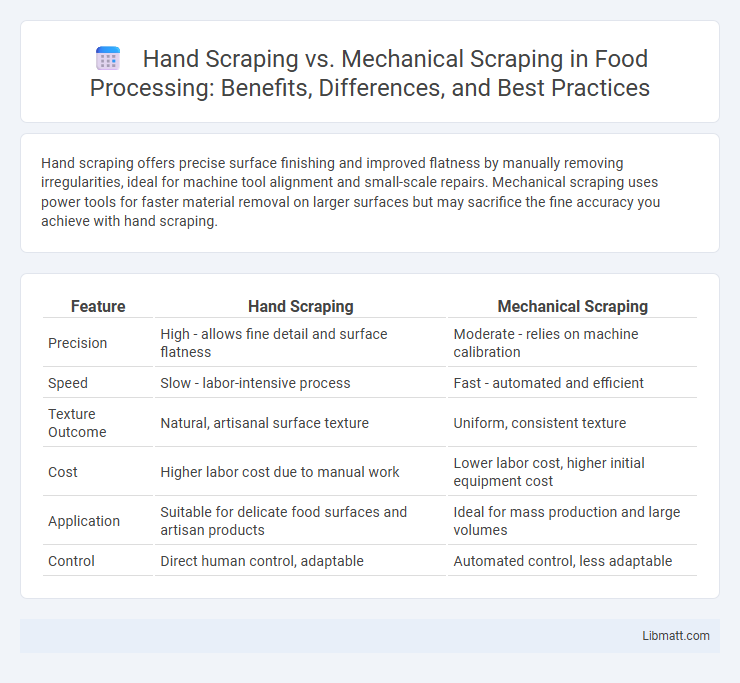

Hand scraping offers precise surface finishing and improved flatness by manually removing irregularities, ideal for machine tool alignment and small-scale repairs. Mechanical scraping uses power tools for faster material removal on larger surfaces but may sacrifice the fine accuracy you achieve with hand scraping.

Table of Comparison

| Feature | Hand Scraping | Mechanical Scraping |

|---|---|---|

| Precision | High - allows fine detail and surface flatness | Moderate - relies on machine calibration |

| Speed | Slow - labor-intensive process | Fast - automated and efficient |

| Texture Outcome | Natural, artisanal surface texture | Uniform, consistent texture |

| Cost | Higher labor cost due to manual work | Lower labor cost, higher initial equipment cost |

| Application | Suitable for delicate food surfaces and artisan products | Ideal for mass production and large volumes |

| Control | Direct human control, adaptable | Automated control, less adaptable |

Introduction to Hand Scraping and Mechanical Scraping

Hand scraping is a precision machining process involving the manual removal of small amounts of material using a scraping tool, typically used to achieve flatness, fit, and finish on metal surfaces. Mechanical scraping, in contrast, employs powered equipment such as milling machines or grinders to remove material more rapidly, often sacrificing the fine tolerances achievable by hand scraping. Both techniques are integral in manufacturing and maintenance, with hand scraping favored for high-accuracy applications and mechanical scraping for faster, bulk material removal.

Historical Background of Scraping Techniques

Hand scraping originated in the early 19th century as a precision method in machine tool manufacturing, allowing artisans to create flat surfaces with high accuracy through manual skill. Mechanical scraping emerged in the mid-20th century, utilizing powered tools to replicate the hand scraping process with increased speed and consistency while maintaining precise flatness. Both techniques revolutionized surface finishing, with hand scraping prized for its artisanal accuracy and mechanical scraping valued for efficiency in industrial applications.

Principles of Hand Scraping

Hand scraping relies on skillful manual abrasion using a scraping tool to create precise, flat, and highly accurate surfaces by selectively removing high spots. Unlike mechanical scraping, which depends on machines for uniform material removal, hand scraping ensures superior surface geometry and contact between mating parts, enhancing machine performance and longevity. Your ability to master the principles of hand scraping, including pattern recognition and pressure control, directly impacts the quality and precision of the final surface finish.

Principles of Mechanical Scraping

Mechanical scraping relies on precision-guided tools to remove material uniformly from a surface, ensuring flatness and high accuracy. This method uses calibrated machines and controlled pressure to achieve consistent surface finish and tight tolerances that hand scraping may lack. Your choice of mechanical scraping accelerates the process and enhances repeatability in manufacturing or maintenance tasks.

Accuracy and Surface Finish Comparison

Hand scraping offers superior accuracy by allowing precise material removal guided by skilled craftsmanship, resulting in a finely tuned surface finish with enhanced flatness and contact area. Mechanical scraping, while faster and more consistent for larger surfaces, generally produces a less refined finish with slightly lower accuracy due to machine limitations in detecting subtle surface imperfections. Your choice depends on the criticality of precision, with hand scraping preferred for achieving the highest surface finish quality and dimensional accuracy.

Speed and Efficiency Analysis

Mechanical scraping offers significantly faster and more consistent material removal compared to hand scraping, making it ideal for large-scale or repetitive tasks. Hand scraping provides superior precision and surface finish, but at the cost of time and labor intensity, reducing overall efficiency in high-volume production. Your choice depends on prioritizing speed and efficiency for rapid results or meticulous quality for detailed work.

Tooling and Equipment Requirements

Hand scraping requires basic tools such as scraper blades, burnishers, and flat surface plates, enabling precise manual material removal and surface finishing. Mechanical scraping involves machinery like power scrapers or CNC equipment, offering faster processing but requiring specialized tooling and maintenance. Your choice depends on the desired accuracy and available resources for tooling and equipment investment.

Common Applications in Industry

Hand scraping is commonly used in precision engineering industries such as machine tool rebuilding, optical instrument manufacture, and the maintenance of high-accuracy machine beds where surface flatness and alignment are critical. Mechanical scraping, often performed using power tools or automated machines, is preferred in large-scale manufacturing for preparing surfaces on engine blocks, heavy machinery bases, and metal fabrication where faster material removal is required. Both methods are essential in industries like aerospace, automotive, and industrial equipment manufacturing to ensure optimal surface contact and assembly accuracy.

Cost Considerations and ROI

Hand scraping requires lower upfront costs due to minimal equipment investment, making it suitable for small-scale or specialized projects, while mechanical scraping involves higher initial expenses for machinery but offers faster processing and consistency. Your return on investment (ROI) depends on project scale and accuracy needs; hand scraping can yield high precision and durability, reducing long-term maintenance costs. Mechanical scraping provides efficiency and scalability, often resulting in quicker project completion and higher throughput, which benefits larger operations seeking cost-effective productivity.

Choosing the Right Scraping Method

Choosing the right scraping method depends on the surface material, precision requirements, and project scale. Hand scraping offers superior flatness and is ideal for restoring machinery where exact tolerances are crucial, while mechanical scraping provides faster material removal suited for less precise applications. Evaluating factors such as cost, surface finish, and labor intensity ensures optimal selection between hand and mechanical scraping techniques.

hand scraping vs mechanical scraping Infographic

libmatt.com

libmatt.com