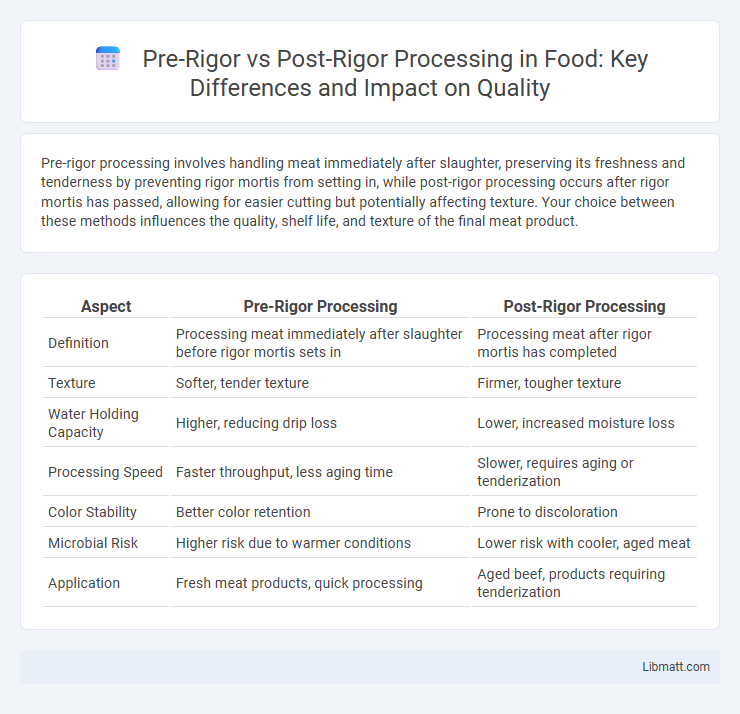

Pre-rigor processing involves handling meat immediately after slaughter, preserving its freshness and tenderness by preventing rigor mortis from setting in, while post-rigor processing occurs after rigor mortis has passed, allowing for easier cutting but potentially affecting texture. Your choice between these methods influences the quality, shelf life, and texture of the final meat product.

Table of Comparison

| Aspect | Pre-Rigor Processing | Post-Rigor Processing |

|---|---|---|

| Definition | Processing meat immediately after slaughter before rigor mortis sets in | Processing meat after rigor mortis has completed |

| Texture | Softer, tender texture | Firmer, tougher texture |

| Water Holding Capacity | Higher, reducing drip loss | Lower, increased moisture loss |

| Processing Speed | Faster throughput, less aging time | Slower, requires aging or tenderization |

| Color Stability | Better color retention | Prone to discoloration |

| Microbial Risk | Higher risk due to warmer conditions | Lower risk with cooler, aged meat |

| Application | Fresh meat products, quick processing | Aged beef, products requiring tenderization |

Introduction to Pre-Rigor and Post-Rigor Processing

Pre-rigor processing involves handling meat immediately after animal slaughter, preserving muscle biochemistry and enhancing tenderness, flavor, and water-holding capacity. Post-rigor processing occurs after rigor mortis completion, offering greater ease in handling and aging but potentially compromising texture and moisture retention. These contrasting methods significantly impact meat quality, shelf life, and consumer sensory experience.

Understanding Muscle Rigor in Meat Processing

Pre-rigor processing involves handling meat immediately after slaughter, before rigor mortis sets in, preserving muscle flexibility and improving tenderness and water retention. Post-rigor processing occurs after rigor mortis has developed and resolved, resulting in firmer texture but potentially reduced juiciness and increased drip loss. Understanding muscle rigor's biochemical changes, including ATP depletion and actin-myosin cross-bridge formation, is crucial for optimizing meat quality in both pre- and post-rigor processing methods.

Pre-Rigor Processing: Definition and Key Steps

Pre-rigor processing refers to the handling and treatment of meat immediately after the animal's death but before the onset of rigor mortis. Key steps include rapid chilling, electrical stimulation, and timely deboning, which help maintain meat quality by minimizing protein denaturation and improving tenderness. This approach contrasts with post-rigor processing, where meat is treated after rigor mortis, often leading to different texture and shelf-life characteristics.

Post-Rigor Processing: Definition and Key Steps

Post-rigor processing refers to the handling of meat after the rigor mortis phase has completed, ensuring improved tenderness, flavor, and shelf life. Key steps include aging to enhance enzyme activity, trimming excess fat and connective tissue, and applying packaging techniques such as vacuum sealing to prevent microbial growth. Your meat's quality is significantly influenced by how effectively these post-rigor procedures are executed.

Biochemical Differences Between Pre-Rigor and Post-Rigor Meat

Pre-rigor meat exhibits higher ATP and glycogen levels, which delay pH decline and result in increased tenderness and water-holding capacity due to limited protein denaturation. In contrast, post-rigor meat undergoes extensive proteolysis, leading to decreased ATP, lower pH, and firmer texture caused by protein cross-linking and aggregation. Understanding these biochemical differences allows you to optimize meat processing techniques for improved quality and shelf life.

Impact on Meat Quality and Shelf Life

Pre-rigor processing preserves muscle enzymes and water-holding capacity, resulting in improved tenderness, juiciness, and extended shelf life due to slower microbial growth. Post-rigor processing, which occurs after muscle stiffening subsides, typically offers consistent texture but may reduce meat's water retention and accelerate spoilage. Your choice between pre-rigor and post-rigor processing directly influences the freshness and sensory quality of the final meat product.

Functional Properties: Texture, Flavor, and Juiciness

Pre-rigor processing enhances meat texture by preserving muscle integrity, resulting in firmer and more tender products with improved water retention, which boosts juiciness. Flavor development is intensified in pre-rigor meat due to reduced enzymatic degradation and better retention of natural compounds compared to post-rigor processing. Post-rigor processing often leads to a softer texture and diminished juiciness as proteins undergo degradation and moisture loss occurs, affecting overall sensory quality.

Industrial Applications and Process Efficiency

Pre-rigor processing enhances industrial applications by enabling faster production cycles, improved meat texture, and reduced microbial growth, leading to higher product quality and extended shelf life. Post-rigor processing, while slower, provides greater flexibility in handling and slicing, catering to diverse market requirements but may increase processing time and energy costs. Optimizing your choice between pre-rigor and post-rigor methods depends on balancing speed, product characteristics, and operational efficiency for your specific industrial goals.

Market Trends and Consumer Preferences

Pre-rigor processing gains traction in the meat industry due to consumer demand for fresher, higher-quality products with enhanced tenderness and juiciness, driving market growth. Post-rigor processing remains prevalent for its extended shelf life and convenience, appealing to cost-conscious buyers and large-scale retail operations. Innovations in pre-rigor techniques are expanding market share as health-conscious consumers prioritize natural texture and flavor profiles over prolonged storage benefits.

Conclusion: Choosing the Right Processing Method

Choosing the right processing method depends on the desired texture, flavor, and shelf life of your meat product. Pre-rigor processing enhances tenderness and juiciness by preserving muscle structure before rigor mortis sets, while post-rigor processing offers improved ease of handling and extended shelf stability. Evaluating these factors helps optimize quality and efficiency in meat production.

pre-rigor processing vs post-rigor processing Infographic

libmatt.com

libmatt.com