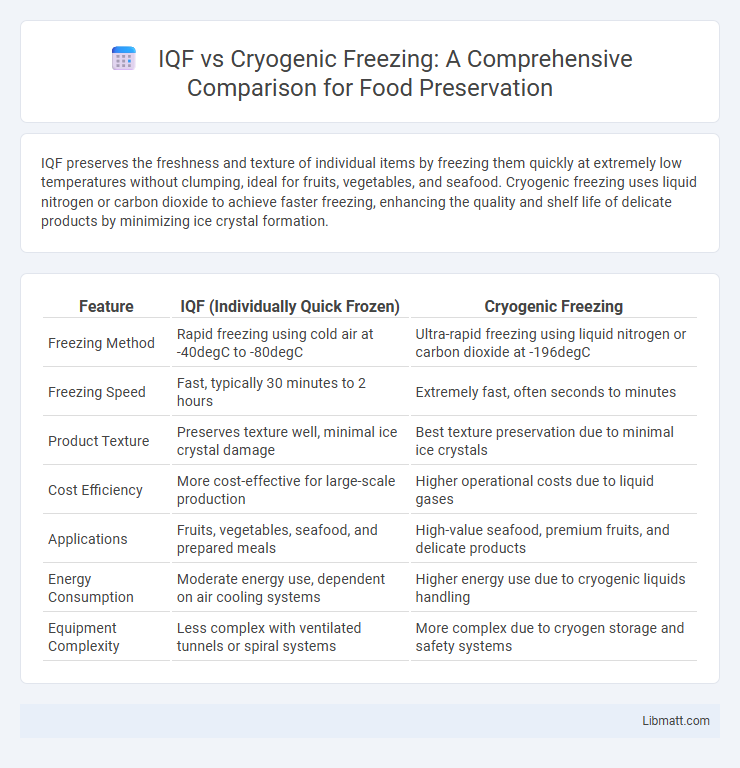

IQF preserves the freshness and texture of individual items by freezing them quickly at extremely low temperatures without clumping, ideal for fruits, vegetables, and seafood. Cryogenic freezing uses liquid nitrogen or carbon dioxide to achieve faster freezing, enhancing the quality and shelf life of delicate products by minimizing ice crystal formation.

Table of Comparison

| Feature | IQF (Individually Quick Frozen) | Cryogenic Freezing |

|---|---|---|

| Freezing Method | Rapid freezing using cold air at -40degC to -80degC | Ultra-rapid freezing using liquid nitrogen or carbon dioxide at -196degC |

| Freezing Speed | Fast, typically 30 minutes to 2 hours | Extremely fast, often seconds to minutes |

| Product Texture | Preserves texture well, minimal ice crystal damage | Best texture preservation due to minimal ice crystals |

| Cost Efficiency | More cost-effective for large-scale production | Higher operational costs due to liquid gases |

| Applications | Fruits, vegetables, seafood, and prepared meals | High-value seafood, premium fruits, and delicate products |

| Energy Consumption | Moderate energy use, dependent on air cooling systems | Higher energy use due to cryogenic liquids handling |

| Equipment Complexity | Less complex with ventilated tunnels or spiral systems | More complex due to cryogen storage and safety systems |

Introduction to IQF and Cryogenic Freezing

IQF (Individually Quick Frozen) technology rapidly freezes individual food items to preserve texture, flavor, and nutritional value without forming large ice crystals. Cryogenic freezing uses extremely low temperatures with liquid nitrogen or carbon dioxide to freeze products instantly, ensuring minimal cellular damage and extending shelf life. Understanding the differences in freezing methods helps optimize your food processing for quality and efficiency.

Understanding IQF (Individual Quick Freezing) Technology

IQF (Individual Quick Freezing) technology rapidly freezes individual food items at extremely low temperatures, preserving their texture, taste, and nutritional value without forming large ice crystals. This method contrasts with Cryogenic Freezing, which uses liquid nitrogen or carbon dioxide but offers similar rapid freezing benefits. IQF ensures minimal product clumping and optimal quality retention in frozen fruits, vegetables, seafood, and bakery items.

What is Cryogenic Freezing?

Cryogenic freezing involves rapidly freezing food products using extremely low temperatures often achieved with liquid nitrogen or carbon dioxide, preserving texture, flavor, and nutritional value by preventing ice crystal formation. This method outperforms IQF (Individually Quick Frozen) in maintaining superior quality for delicate items like seafood and berries. Your choice between IQF and cryogenic freezing depends on the specific food type and desired preservation standards.

Key Differences Between IQF and Cryogenic Freezing

IQF (Individually Quick Frozen) uses rapid freezing with cold air to freeze products quickly without clumping, preserving texture and quality. Cryogenic freezing employs liquid nitrogen or carbon dioxide for ultra-fast freezing at extremely low temperatures, resulting in smaller ice crystals and superior product integrity. Your choice depends on product type, desired texture, and production scale, with cryogenic offering faster freezing but higher operational costs.

Advantages of IQF Freezing

IQF freezing offers superior product quality by individually freezing items, preventing clumping and maintaining original texture and flavor. This method ensures faster freezing times compared to cryogenic freezing, reducing ice crystal formation and preserving nutritional value. IQF systems improve storage efficiency and facilitate easy portion control, making them ideal for large-scale food processing operations.

Benefits of Cryogenic Freezing

Cryogenic freezing offers superior preservation of food quality by rapidly lowering temperatures with liquid nitrogen, minimizing ice crystal formation that damages cellular structure. This method enhances shelf life and maintains nutritional content, texture, and flavor better than IQF (Individually Quick Frozen) techniques. Its ultra-fast freezing process also reduces drip loss and microbial growth, ensuring higher food safety and product integrity.

Applications in the Food Industry

IQF (Individually Quick Frozen) technology rapidly freezes individual food items like fruits, vegetables, and seafood to maintain texture and nutritional value, making it ideal for portion-controlled packaging and convenience foods. Cryogenic freezing uses liquid nitrogen or carbon dioxide to achieve ultra-low temperatures quickly, preserving delicate products such as berries, herbs, and premium seafood with minimal cellular damage. Your choice between IQF and cryogenic freezing depends on product type, desired quality, and processing speed requirements in the food industry.

Cost Analysis: IQF vs Cryogenic Freezing

IQF (Individually Quick Frozen) systems generally have lower upfront equipment costs compared to cryogenic freezing, which requires expensive cryogen gases such as liquid nitrogen or carbon dioxide. Operating costs for IQF are typically more energy-intensive but stable over time, whereas cryogenic freezing incurs higher variable costs due to continuous cryogen supply and handling. From a cost analysis perspective, IQF is often more cost-effective for large-volume, high-throughput operations, while cryogenic freezing suits smaller batches with a premium on food quality and rapid freezing.

Quality and Texture: Impact on Frozen Products

IQF (Individually Quick Frozen) technology preserves the quality and texture of frozen products by rapidly freezing items separately, which minimizes ice crystal formation and maintains cell integrity. Cryogenic freezing uses liquid nitrogen or carbon dioxide at extremely low temperatures, resulting in faster freezing times that further reduce moisture loss and preserve a product's original texture and flavor. Both methods enhance the frozen product's quality, but cryogenic freezing often achieves superior texture retention due to its ultra-fast freezing rate.

Choosing the Best Freezing Method for Your Business

IQF (Individual Quick Freezing) preserves food quality by rapidly freezing individual pieces, ideal for maintaining texture and flavor in fruits, vegetables, and seafood. Cryogenic freezing uses liquid nitrogen or carbon dioxide for ultra-fast freezing, offering superior preservation of delicate products and minimal ice crystal formation, crucial for premium seafood and gourmet items. Selecting the best method depends on product type, desired shelf life, and budget, with IQF favored for cost-effectiveness and cryogenic for high-quality, small-batch applications.

IQF vs Cryogenic Freezing Infographic

libmatt.com

libmatt.com