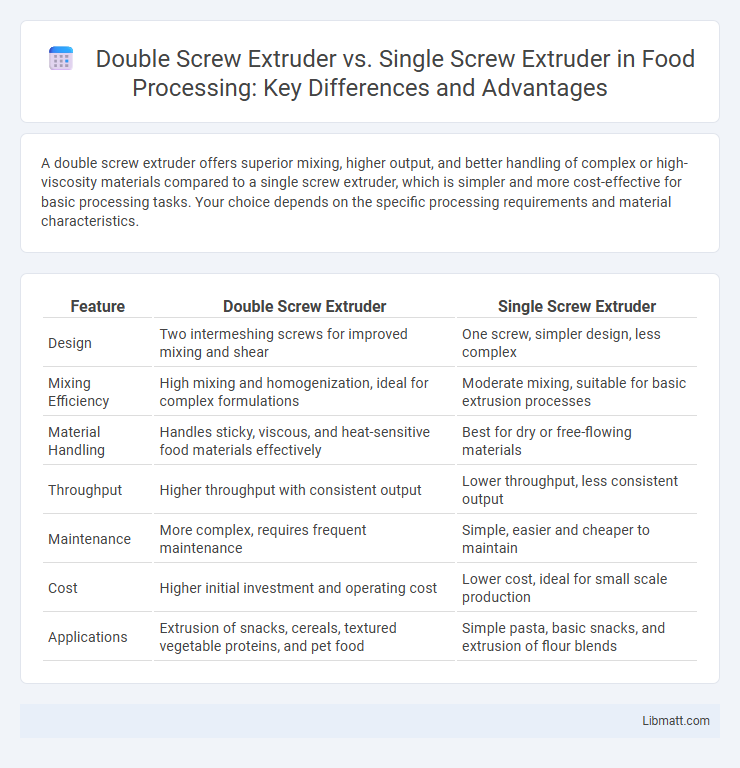

A double screw extruder offers superior mixing, higher output, and better handling of complex or high-viscosity materials compared to a single screw extruder, which is simpler and more cost-effective for basic processing tasks. Your choice depends on the specific processing requirements and material characteristics.

Table of Comparison

| Feature | Double Screw Extruder | Single Screw Extruder |

|---|---|---|

| Design | Two intermeshing screws for improved mixing and shear | One screw, simpler design, less complex |

| Mixing Efficiency | High mixing and homogenization, ideal for complex formulations | Moderate mixing, suitable for basic extrusion processes |

| Material Handling | Handles sticky, viscous, and heat-sensitive food materials effectively | Best for dry or free-flowing materials |

| Throughput | Higher throughput with consistent output | Lower throughput, less consistent output |

| Maintenance | More complex, requires frequent maintenance | Simple, easier and cheaper to maintain |

| Cost | Higher initial investment and operating cost | Lower cost, ideal for small scale production |

| Applications | Extrusion of snacks, cereals, textured vegetable proteins, and pet food | Simple pasta, basic snacks, and extrusion of flour blends |

Introduction to Screw Extruders

Screw extruders are essential machines in plastic processing, where the screw design directly impacts efficiency and product quality. Double screw extruders feature two intermeshing screws, providing superior mixing, higher output, and better temperature control compared to single screw extruders, which have a single rotating screw primarily suited for simple melting and conveying tasks. The choice between single and double screw extruders depends on application requirements such as material homogeneity, processing versatility, and operational stability.

Core Differences: Double vs. Single Screw

Double screw extruders offer superior mixing and higher output rates due to the intermeshing screws that provide consistent shear and better material homogeneity compared to single screw extruders, which rely on one screw for both conveying and melting. Single screw extruders are simpler, cost-effective, and ideal for processing homogeneous materials with lower viscosity, while double screw models excel in handling complex formulations and materials with fillers or additives. Your choice between these two should consider the required processing efficiency, material type, and production scale to optimize performance and product quality.

Mechanism and Design Features

Double screw extruders feature two intermeshing screws that provide enhanced mixing, consistent material flow, and superior shear control, making them ideal for processing complex or heat-sensitive materials. Single screw extruders rely on a single rotating screw within a barrel, characterized by simpler design and lower cost but less effective at mixing and managing high-viscosity materials. Your choice depends on the desired processing efficiency, material characteristics, and product quality requirements tied to these distinct mechanism and design features.

Material Compatibility and Processing

Double screw extruders offer superior material compatibility by efficiently processing a wider range of polymers, including high-viscosity and heat-sensitive materials, through enhanced mixing and consistent shear forces. Single screw extruders are best suited for simpler, homogeneous materials but may struggle with compounding or materials requiring precise temperature control. Your choice depends on the complexity of the material and the specific processing requirements to ensure optimal product quality.

Throughput and Output Quality

Double screw extruders offer higher throughput compared to single screw extruders due to their enhanced mixing and consistent melting capabilities, resulting in improved output quality with fewer defects. Single screw extruders typically handle lower volumes and may produce less uniform products, making them suitable for simpler processing tasks. You can achieve superior production efficiency and product consistency by choosing a double screw extruder for complex or high-volume applications.

Mixing and Homogenization Capabilities

Double screw extruders offer superior mixing and homogenization capabilities compared to single screw extruders due to intermeshing screws that generate intensive shear and distributive mixing. The co-rotating or counter-rotating twin screws facilitate efficient heat transfer and consistent material dispersion, crucial for compounding polymers and additives. Single screw extruders tend to have limited mixing efficiency, primarily suitable for melting and conveying rather than thorough homogenization.

Energy Efficiency Comparison

Double screw extruders offer higher energy efficiency than single screw extruders by providing better mixing and heat transfer, which reduces processing time and lowers energy consumption. Single screw extruders generally consume more energy due to uneven material flow and less effective shear heating, leading to longer operation times. When optimizing Your production process, choosing a double screw extruder can result in significant energy savings and improved overall performance.

Maintenance and Operational Costs

Double screw extruders generally involve higher maintenance and operational costs due to their complex design and increased number of moving parts compared to single screw extruders. You may experience more frequent part replacements and specialized servicing requirements, which can elevate downtime and expenses. Single screw extruders typically offer lower costs and simpler maintenance, making them more cost-effective for straightforward extrusion processes.

Application Areas and Industry Use Cases

Double screw extruders excel in complex polymer blending, compounding, and reactive extrusion applications across industries like automotive, pharmaceuticals, and food processing, where precise mixing and high shear are critical. Single screw extruders are widely used for simpler tasks such as plastic film, pipe, and profile extrusion, benefiting industries focused on continuous, high-throughput production with less demanding mixing requirements. Your choice depends on the specific material handling needs and process complexity of your manufacturing application.

Conclusion: Choosing the Optimal Extruder

Double screw extruders offer enhanced mixing and higher output, ideal for complex formulations and consistent product quality. Single screw extruders provide simpler design and lower cost, suitable for straightforward processing and lower volume production. Selecting the optimal extruder depends on specific production needs, material properties, and desired efficiency in the manufacturing process.

double screw extruder vs single screw extruder Infographic

libmatt.com

libmatt.com