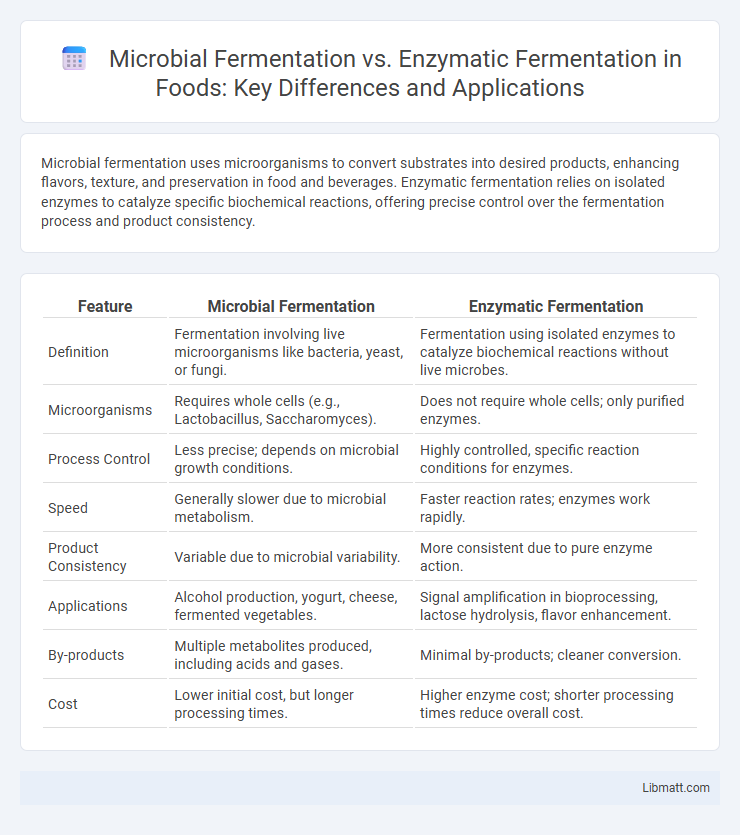

Microbial fermentation uses microorganisms to convert substrates into desired products, enhancing flavors, texture, and preservation in food and beverages. Enzymatic fermentation relies on isolated enzymes to catalyze specific biochemical reactions, offering precise control over the fermentation process and product consistency.

Table of Comparison

| Feature | Microbial Fermentation | Enzymatic Fermentation |

|---|---|---|

| Definition | Fermentation involving live microorganisms like bacteria, yeast, or fungi. | Fermentation using isolated enzymes to catalyze biochemical reactions without live microbes. |

| Microorganisms | Requires whole cells (e.g., Lactobacillus, Saccharomyces). | Does not require whole cells; only purified enzymes. |

| Process Control | Less precise; depends on microbial growth conditions. | Highly controlled, specific reaction conditions for enzymes. |

| Speed | Generally slower due to microbial metabolism. | Faster reaction rates; enzymes work rapidly. |

| Product Consistency | Variable due to microbial variability. | More consistent due to pure enzyme action. |

| Applications | Alcohol production, yogurt, cheese, fermented vegetables. | Signal amplification in bioprocessing, lactose hydrolysis, flavor enhancement. |

| By-products | Multiple metabolites produced, including acids and gases. | Minimal by-products; cleaner conversion. |

| Cost | Lower initial cost, but longer processing times. | Higher enzyme cost; shorter processing times reduce overall cost. |

Introduction to Fermentation: Microbial vs Enzymatic

Microbial fermentation utilizes microorganisms such as bacteria, yeast, or fungi to convert organic substrates into desired products like alcohol, acids, or gases through metabolic processes. Enzymatic fermentation involves isolated enzymes catalyzing specific biochemical reactions without the presence of living cells, enabling more controlled and selective product formation. Both methods are pivotal in biotechnology industries, with microbial fermentation widely used in food and biofuel production, while enzymatic fermentation is favored in pharmaceuticals and fine chemical synthesis.

Understanding Microbial Fermentation

Microbial fermentation involves using microorganisms such as bacteria, yeast, or fungi to convert organic substrates into valuable products like alcohol, acids, or gases through metabolic processes. This method is essential for producing items like yogurt, beer, and biofuels by exploiting the natural enzymatic activity within microbes. Understanding microbial fermentation helps optimize conditions like temperature, pH, and nutrient availability to enhance yield and product quality in your biotechnological applications.

Exploring Enzymatic Fermentation

Enzymatic fermentation utilizes specific enzymes to catalyze biochemical reactions, producing desired compounds with precision and efficiency compared to microbial fermentation, which relies on whole microorganisms. This method offers greater control over reaction conditions, resulting in higher purity and yield of products such as biofuels, pharmaceuticals, and food additives. Understanding enzymatic fermentation allows you to optimize production processes and tailor outputs for specialized industrial applications.

Key Differences Between Microbial and Enzymatic Fermentation

Microbial fermentation relies on living microorganisms such as bacteria, yeast, or fungi to convert substrates into desired products, whereas enzymatic fermentation uses isolated enzymes to catalyze specific biochemical reactions without living cells. Microbial fermentation often involves complex metabolic pathways and produces multiple byproducts, while enzymatic fermentation offers higher specificity, faster reaction rates, and easier control over reaction conditions. The scalability and cost-effectiveness of microbial fermentation make it suitable for large-scale production of biofuels, pharmaceuticals, and food products, whereas enzymatic fermentation is preferred for precision applications like high-purity biochemical synthesis and food processing.

Microorganisms Involved in Microbial Fermentation

Microbial fermentation primarily involves bacteria, yeasts, and molds such as Lactobacillus, Saccharomyces cerevisiae, and Aspergillus species, which drive biochemical transformations by metabolizing sugars under anaerobic conditions. These microorganisms produce enzymes and metabolites like lactic acid, ethanol, and organic acids, essential for the fermentation process in food, beverage, and pharmaceutical industries. The specific strain selection and environmental factors directly influence the efficiency, yield, and product specificity of microbial fermentation.

Types of Enzymes Used in Enzymatic Fermentation

Enzymatic fermentation primarily utilizes specific enzymes such as amylases, proteases, lipases, and cellulases to catalyze biochemical reactions, targeting carbohydrates, proteins, fats, and cellulose respectively. These enzymes facilitate the breakdown of complex substrates into simpler molecules, enhancing the efficiency and specificity of the fermentation process compared to microbial fermentation, which relies on entire microorganisms producing a range of enzymes. Understanding the types of enzymes in enzymatic fermentation allows you to optimize conditions for improved yield and product quality.

Applications in Food and Beverage Industries

Microbial fermentation utilizes bacteria, yeast, or molds to convert sugars into products like yogurt, beer, and sourdough, essential for developing flavor, texture, and preservation in food and beverages. Enzymatic fermentation employs isolated enzymes to catalyze specific biochemical reactions, enhancing processes such as lactose hydrolysis in dairy or starch breakdown in brewing for improved efficiency and product consistency. Both methods are pivotal in the industry, with microbial fermentation driving traditional food cultures and enzymatic fermentation optimizing industrial-scale production and ingredient modification.

Efficiency and Yield Comparison

Microbial fermentation often achieves higher yield rates due to the ability of microorganisms to rapidly reproduce and efficiently convert substrates into desired products, making it suitable for large-scale industrial applications. Enzymatic fermentation provides greater specificity and faster reaction rates, enhancing efficiency in processes requiring targeted biochemical transformations with minimal by-products. Your choice between these methods depends on balancing the scale of production and the precision of the desired outcome for optimal efficiency and yield.

Safety, Quality, and Regulatory Considerations

Microbial fermentation leverages live microorganisms to produce complex metabolites, requiring stringent safety assessments to prevent contamination and ensure product consistency, with regulatory oversight focusing on controlled microbial strains and bioprocess parameters. Enzymatic fermentation involves isolated enzymes catalyzing specific biochemical reactions, reducing contamination risk and enhancing product purity, which simplifies quality control and regulatory approval processes due to defined enzyme sources and reaction conditions. Both fermentation types must comply with food safety standards such as FDA and EFSA guidelines, emphasizing toxin absence, allergen management, and traceability to meet consumer safety and quality expectations.

Future Trends and Innovations in Fermentation Technologies

Future trends in fermentation technologies emphasize enhanced precision and sustainability through genetic engineering and synthetic biology, driving innovations in both microbial and enzymatic fermentation. Advances in AI-driven optimization enable more efficient substrate utilization and product yield, reshaping industrial applications ranging from biofuels to pharmaceuticals. Your ability to leverage these cutting-edge fermentation processes ensures competitive advantage in developing cost-effective, eco-friendly bioproducts.

Microbial Fermentation vs Enzymatic Fermentation Infographic

libmatt.com

libmatt.com