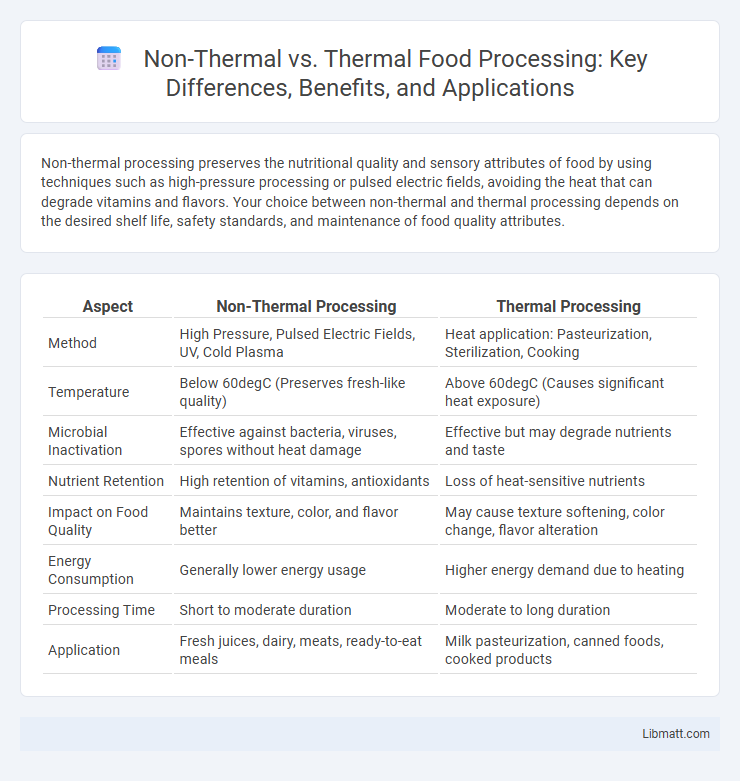

Non-thermal processing preserves the nutritional quality and sensory attributes of food by using techniques such as high-pressure processing or pulsed electric fields, avoiding the heat that can degrade vitamins and flavors. Your choice between non-thermal and thermal processing depends on the desired shelf life, safety standards, and maintenance of food quality attributes.

Table of Comparison

| Aspect | Non-Thermal Processing | Thermal Processing |

|---|---|---|

| Method | High Pressure, Pulsed Electric Fields, UV, Cold Plasma | Heat application: Pasteurization, Sterilization, Cooking |

| Temperature | Below 60degC (Preserves fresh-like quality) | Above 60degC (Causes significant heat exposure) |

| Microbial Inactivation | Effective against bacteria, viruses, spores without heat damage | Effective but may degrade nutrients and taste |

| Nutrient Retention | High retention of vitamins, antioxidants | Loss of heat-sensitive nutrients |

| Impact on Food Quality | Maintains texture, color, and flavor better | May cause texture softening, color change, flavor alteration |

| Energy Consumption | Generally lower energy usage | Higher energy demand due to heating |

| Processing Time | Short to moderate duration | Moderate to long duration |

| Application | Fresh juices, dairy, meats, ready-to-eat meals | Milk pasteurization, canned foods, cooked products |

Introduction to Food Processing Technologies

Non-thermal processing techniques, including high-pressure processing (HPP), pulsed electric fields (PEF), and cold plasma, preserve food quality by minimizing heat-induced nutrient degradation and sensory changes. Thermal processing, such as pasteurization and sterilization, relies on heat to inactivate microorganisms and enzymes, ensuring food safety but often impacting texture and flavor. Advances in non-thermal technologies offer energy-efficient and sustainable alternatives that enhance shelf life while maintaining nutritional and sensory attributes.

Defining Non-Thermal Processing

Non-thermal processing refers to food preservation methods that inactivate microorganisms and enzymes without using high temperatures, thus maintaining the food's nutritional value, flavor, and texture. Techniques such as high-pressure processing (HPP), pulsed electric fields (PEF), and cold plasma effectively enhance food safety and shelf life while preserving sensory qualities. This contrasts with thermal processing, which relies on heat to ensure microbial destruction but often leads to nutrient loss and quality degradation.

Understanding Thermal Processing

Thermal processing uses heat to inactivate microorganisms and enzymes, ensuring food safety and extending shelf life through methods like pasteurization and sterilization. This technique relies on precise temperature control and exposure time to prevent nutrient loss and maintain food quality. Understanding thermal processing helps optimize conditions to balance microbial inactivation with preserving sensory and nutritional attributes.

Key Differences Between Non-Thermal and Thermal Methods

Non-thermal processing preserves food quality by using techniques like high-pressure processing, pulsed electric fields, and cold plasma, which inactivate microbes without heat, maintaining nutrients and sensory properties. Thermal processing relies on heat to destroy pathogens and enzymes but can cause nutrient loss, texture changes, and flavor alterations in your products. Understanding these differences helps optimize food safety while retaining freshness and nutritional value.

Effect on Food Quality and Nutrition

Non-thermal processing techniques such as high-pressure processing (HPP) and pulsed electric fields (PEF) preserve food quality by maintaining flavor, texture, and color while retaining higher levels of heat-sensitive nutrients like vitamins and antioxidants. In contrast, thermal processing methods including pasteurization and sterilization often degrade nutrient content, cause textural changes, and diminish sensory attributes due to high heat exposure. Studies show that non-thermal methods effectively inactivate microbes with minimal nutrient loss, ensuring enhanced preservation of food freshness and nutritional value compared to conventional thermal techniques.

Safety and Microbial Inactivation

Non-thermal processing techniques such as high-pressure processing (HPP) and pulsed electric fields (PEF) effectively inactivate pathogens without compromising food quality or nutrients, offering enhanced safety compared to traditional thermal methods. Thermal processing relies on heat to destroy microbes, but it can weaken nutrient content and alter texture while ensuring pathogen reduction. Your choice of processing method influences food safety and shelf life, with non-thermal methods offering precise microbial control while preserving product integrity.

Environmental Impact and Energy Consumption

Non-thermal processing methods, such as high-pressure processing and pulsed electric fields, consume significantly less energy compared to conventional thermal processing techniques, reducing carbon emissions and minimizing environmental impact. Thermal processing often requires prolonged heating, leading to higher energy consumption and increased greenhouse gas emissions due to fossil fuel use. Adoption of non-thermal technologies contributes to sustainable food production by lowering energy use, preserving product quality, and decreasing the overall ecological footprint.

Industrial Applications and Scalability

Non-thermal processing methods, such as high-pressure processing (HPP) and pulsed electric fields (PEF), offer significant advantages in industrial applications by preserving food quality and extending shelf life without heat-induced nutrient loss. These technologies are increasingly scalable, with large-scale commercial units capable of processing bulk quantities efficiently, making them suitable for industries like juice, dairy, and ready-to-eat meals. Thermal processing remains dominant for its proven microbial inactivation and cost-effectiveness at massive scales, especially in canned and frozen foods, but faces limitations in preserving sensory and nutritional properties compared to non-thermal alternatives.

Consumer Perception and Market Trends

Non-thermal processing methods such as high-pressure processing (HPP) and pulsed electric fields (PEF) are gaining consumer trust due to their ability to preserve the fresh taste, nutrients, and texture of food products better than traditional thermal processing. Market trends indicate a growing demand for minimally processed, clean-label foods, driving food manufacturers to adopt non-thermal technologies that align with health-conscious and environmentally aware consumers. Consumer perception favors non-thermal processing as a modern, innovative approach that maintains food safety while reducing the negative impacts of heat, supporting its expanding application across the beverage, dairy, and ready-to-eat meal sectors.

Future Prospects in Food Processing Technologies

Non-thermal processing techniques like high-pressure processing (HPP), pulsed electric fields (PEF), and cold plasma are gaining traction due to their ability to preserve nutrients, flavor, and texture while ensuring microbial safety. Advances in these technologies promise enhanced energy efficiency, reduced environmental impact, and improved shelf life compared to conventional thermal methods. Future food processing innovation will likely integrate hybrid systems combining non-thermal and mild thermal treatments to optimize quality and safety in diverse food matrices.

Non-Thermal Processing vs Thermal Processing Infographic

libmatt.com

libmatt.com