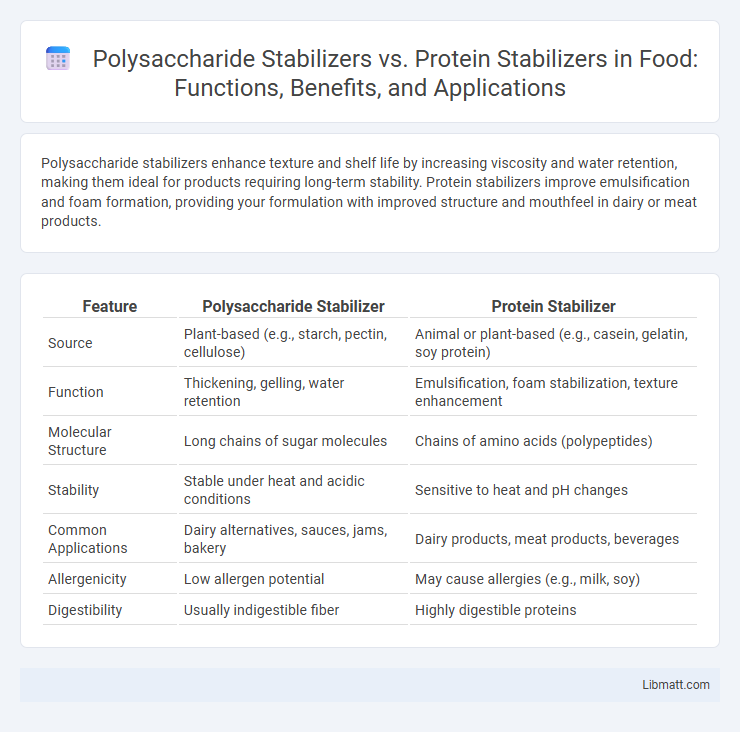

Polysaccharide stabilizers enhance texture and shelf life by increasing viscosity and water retention, making them ideal for products requiring long-term stability. Protein stabilizers improve emulsification and foam formation, providing your formulation with improved structure and mouthfeel in dairy or meat products.

Table of Comparison

| Feature | Polysaccharide Stabilizer | Protein Stabilizer |

|---|---|---|

| Source | Plant-based (e.g., starch, pectin, cellulose) | Animal or plant-based (e.g., casein, gelatin, soy protein) |

| Function | Thickening, gelling, water retention | Emulsification, foam stabilization, texture enhancement |

| Molecular Structure | Long chains of sugar molecules | Chains of amino acids (polypeptides) |

| Stability | Stable under heat and acidic conditions | Sensitive to heat and pH changes |

| Common Applications | Dairy alternatives, sauces, jams, bakery | Dairy products, meat products, beverages |

| Allergenicity | Low allergen potential | May cause allergies (e.g., milk, soy) |

| Digestibility | Usually indigestible fiber | Highly digestible proteins |

Introduction to Food Stabilizers

Food stabilizers enhance texture, consistency, and shelf life in various products by preventing ingredient separation. Polysaccharide stabilizers, derived from carbohydrates like gums and starches, excel in water retention and viscosity control, making them ideal for suspending particles and stabilizing emulsions. Protein stabilizers, sourced from milk, egg whites, or soy, provide emulsification and gel formation, contributing to creamy textures and improved mouthfeel in dairy and meat products.

Understanding Polysaccharide Stabilizers

Polysaccharide stabilizers, derived from natural sources like guar gum or xanthan gum, enhance texture and prevent ice crystal formation in frozen desserts. These stabilizers increase viscosity and moisture retention, improving product consistency and shelf life. Your formulation benefits from polysaccharide stabilizers by achieving a smoother mouthfeel and stable structure without the allergenic concerns sometimes associated with protein stabilizers.

Protein Stabilizers: Characteristics and Functions

Protein stabilizers, such as casein and whey proteins, provide emulsification and film-forming properties crucial for texture and stability in food products. Their amphiphilic nature enables them to adsorb at oil-water interfaces, reducing surface tension and preventing phase separation. These stabilizers also improve mouthfeel and provide nutritional benefits by contributing essential amino acids.

Mechanisms of Stabilization in Food Systems

Polysaccharide stabilizers function by increasing viscosity and creating a gel network that traps water and other food components, preventing phase separation and improving texture. Protein stabilizers stabilize food systems through surface-active properties, forming a protective layer around fat droplets or air bubbles, which inhibits aggregation and maintains emulsion or foam stability. Understanding these mechanisms allows you to select the appropriate stabilizer based on the desired texture and stability in your food formulation.

Key Differences Between Polysaccharide and Protein Stabilizers

Polysaccharide stabilizers, derived from carbohydrates like xanthan gum and guar gum, primarily enhance viscosity and water retention in food systems, while protein stabilizers, such as gelatin and whey protein, improve texture and emulsification through their ability to form gels and bind water. Polysaccharide stabilizers are more resistant to pH and temperature changes, making them ideal for maintaining stability in acidic or heated environments, whereas protein stabilizers offer superior nutritional value and contribute to mouthfeel and creaminess. Understanding these key differences helps you select the appropriate stabilizer to optimize texture, stability, and functionality in your product formulation.

Applications of Polysaccharide Stabilizers in the Food Industry

Polysaccharide stabilizers such as xanthan gum, guar gum, and carrageenan are widely used in the food industry for their ability to improve texture, viscosity, and shelf-life in products like sauces, dairy, and baked goods. These stabilizers help to prevent ingredient separation, enhance mouthfeel, and maintain consistent product quality under varying storage conditions. Their natural origin and compatibility with gluten-free and vegan formulations make them favorable choices over protein stabilizers in plant-based and allergen-sensitive foods.

Common Uses of Protein Stabilizers in Food Products

Protein stabilizers are commonly used in food products such as dairy items, dressings, and baked goods to improve texture, emulsification, and water retention. They enhance the creaminess in yogurt and ice cream, stabilize emulsions in salad dressings, and provide structure in gluten-free baking. Unlike polysaccharide stabilizers, protein stabilizers contribute to nutritional value by adding essential amino acids and improving mouthfeel.

Advantages and Limitations of Each Stabilizer Type

Polysaccharide stabilizers, such as xanthan gum and guar gum, offer excellent viscosity enhancement and water retention, making them ideal for maintaining texture and stability in aqueous food systems but can sometimes lead to undesirable gelation or phase separation under certain conditions. Protein stabilizers, including casein and whey protein, provide superior emulsification and foam stabilization due to their amphiphilic nature, though they may be sensitive to pH changes, temperature fluctuations, and enzymatic degradation, limiting their use in some formulations. Both stabilizer types require careful selection based on the specific product matrix and processing conditions to optimize texture, shelf life, and sensory attributes.

Factors Influencing Stabilizer Selection

The selection of polysaccharide versus protein stabilizers depends on factors such as the desired viscosity, pH tolerance, and interaction with other formulation components. Polysaccharide stabilizers like xanthan gum offer high stability in acidic conditions and contribute to gel formation, whereas protein stabilizers such as gelatin provide excellent emulsification and foam stabilization but are sensitive to heat and pH changes. The choice also hinges on allergenicity concerns, dietary restrictions, and regulatory status in food or pharmaceutical applications.

Future Trends in Food Stabilization Technologies

Emerging food stabilization technologies emphasize the integration of polysaccharide stabilizers and protein stabilizers to enhance texture, shelf life, and nutritional value. Innovations focus on hybrid stabilizer systems combining the gel-forming properties of polysaccharides with the emulsifying capabilities of proteins, optimizing food product stability under varying processing conditions. Your preference for clean label and natural ingredients is driving research towards sustainable, plant-based stabilizers with multifunctional benefits in future food formulations.

Polysaccharide Stabilizer vs Protein Stabilizer Infographic

libmatt.com

libmatt.com