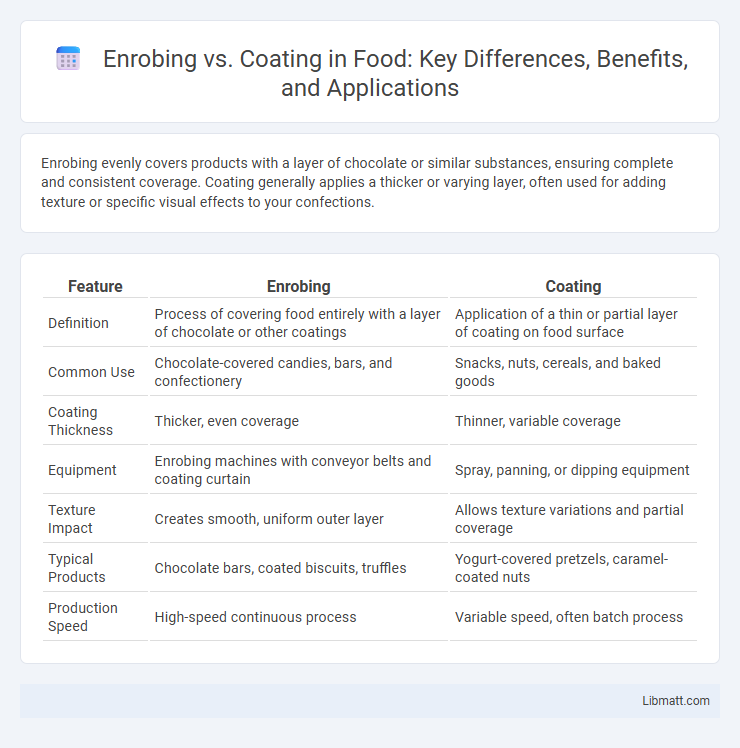

Enrobing evenly covers products with a layer of chocolate or similar substances, ensuring complete and consistent coverage. Coating generally applies a thicker or varying layer, often used for adding texture or specific visual effects to your confections.

Table of Comparison

| Feature | Enrobing | Coating |

|---|---|---|

| Definition | Process of covering food entirely with a layer of chocolate or other coatings | Application of a thin or partial layer of coating on food surface |

| Common Use | Chocolate-covered candies, bars, and confectionery | Snacks, nuts, cereals, and baked goods |

| Coating Thickness | Thicker, even coverage | Thinner, variable coverage |

| Equipment | Enrobing machines with conveyor belts and coating curtain | Spray, panning, or dipping equipment |

| Texture Impact | Creates smooth, uniform outer layer | Allows texture variations and partial coverage |

| Typical Products | Chocolate bars, coated biscuits, truffles | Yogurt-covered pretzels, caramel-coated nuts |

| Production Speed | High-speed continuous process | Variable speed, often batch process |

Introduction to Enrobing and Coating

Enrobing involves continuously covering food products with a flowing layer of chocolate or other coatings to achieve a uniform and smooth finish, commonly used in confections and baked goods. Coating refers to the broader process of applying a layer of material such as chocolate, sugar, or glaze onto food items for texture, flavor, or preservation purposes. Both techniques are essential in the food industry for enhancing product appearance, taste, and shelf life, with enrobing specializing in seamless coverage and coating encompassing various application methods.

Defining Enrobing: Process and Applications

Enrobing is a confectionery process where a center, such as nuts or biscuits, is completely covered with a uniform layer of chocolate or coating material using an enrobing machine. This technique ensures consistent thickness and smoothness, enhancing both the aesthetics and taste of products like chocolate bars, candies, and pastries. Enrobing is widely applied in industrial chocolate production, bakery items, and snack foods to improve shelf life and provide a professional finish.

Understanding Coating: Methods and Materials

Coating involves applying a layer of materials such as chocolate, sugar, or syrup onto food products through methods like dipping, spraying, or panning to enhance flavor, texture, and appearance. Common substances used in coating include cocoa butter, confectionery glaze, and caramel, each providing specific sensory and protective properties. Techniques like enrobing use conveyor belts and controlled temperature settings to ensure uniform coating, making it essential in confectionery and snack manufacturing.

Key Differences Between Enrobing and Coating

Enrobing involves fully covering a product with a layer of chocolate or other coatings, providing uniform thickness and complete encapsulation, whereas coating typically refers to applying a thinner, partial layer that enhances surface texture and appearance. Enrobing machines use conveyor belts to pass products through a curtain of coating, while coating methods like spraying or dipping offer more control over the coating thickness. Your choice between enrobing and coating depends on the desired coverage, texture, and production process requirements.

Advantages of Enrobing in Food Production

Enrobing offers superior control over the distribution of coatings such as chocolate or fat, ensuring even coverage and a consistent texture that enhances product quality in food production. Its ability to rapidly enrobe items with minimal waste improves efficiency and cost-effectiveness, particularly in confectionery and snack manufacturing. The process also supports versatile applications, allowing producers to maintain product freshness and extend shelf life by creating protective barriers against moisture and oxygen.

Benefits of Coating Techniques

Coating techniques offer precise control over thickness and uniformity, ensuring consistent product quality across large production batches. These methods enhance the appearance, texture, and shelf-life of confectionery by providing a glossy finish and effective protection against moisture and air. Efficient coating processes also improve productivity through faster application speeds and reduced material waste compared to traditional enrobing.

Common Industries Using Enrobing vs Coating

Enrobing is commonly used in the confectionery and pharmaceutical industries for coating chocolates, candies, and pills with a smooth, uniform layer. Coating processes are widely applied in automotive, aerospace, and electronics sectors to protect surfaces, enhance durability, and improve aesthetics. Your choice between enrobing and coating depends on the specific industry requirements and the product's functional needs.

Equipment Used for Enrobing and Coating

Enrobing equipment primarily features a curtain or pan system that allows products to pass through a flowing layer of chocolate or coating, ensuring an even and consistent coverage. Coating machines use spray or waterfall methods to apply thinner, more controlled layers, often employing air knives or cooling tunnels to achieve precise finishes. Both types of equipment integrate temperature controls and conveyors to maintain product quality and throughput in confectionery production.

Quality Control in Enrobing and Coating Processes

Quality control in enrobing and coating processes ensures consistent coverage and product uniformity by monitoring parameters such as temperature, viscosity, and coating thickness. Advanced sensors and real-time imaging systems detect defects like uneven layers, air bubbles, or contamination, allowing immediate adjustments to maintain product standards. Statistical process control (SPC) techniques analyze production data, minimizing variability and enhancing the overall quality of enrobed and coated products.

Choosing the Right Method: Factors to Consider

Choosing between enrobing and coating depends on factors like product shape, thickness preference, and desired texture; enrobing provides full, uniform coverage ideal for consistent layers, while coating suits thinner, lighter applications with more control. Consider your production scale and speed requirements, as enrobing is often faster for large batches whereas coating allows detailed customization for specialty products. Your choice should align with product specifications, ingredient compatibility, and the final sensory experience you aim to deliver.

Enrobing vs Coating Infographic

libmatt.com

libmatt.com