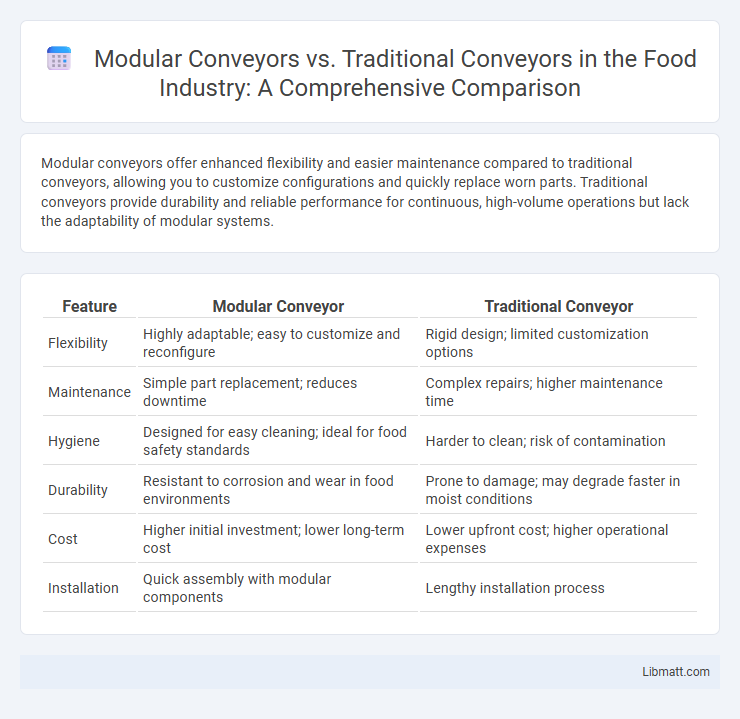

Modular conveyors offer enhanced flexibility and easier maintenance compared to traditional conveyors, allowing you to customize configurations and quickly replace worn parts. Traditional conveyors provide durability and reliable performance for continuous, high-volume operations but lack the adaptability of modular systems.

Table of Comparison

| Feature | Modular Conveyor | Traditional Conveyor |

|---|---|---|

| Flexibility | Highly adaptable; easy to customize and reconfigure | Rigid design; limited customization options |

| Maintenance | Simple part replacement; reduces downtime | Complex repairs; higher maintenance time |

| Hygiene | Designed for easy cleaning; ideal for food safety standards | Harder to clean; risk of contamination |

| Durability | Resistant to corrosion and wear in food environments | Prone to damage; may degrade faster in moist conditions |

| Cost | Higher initial investment; lower long-term cost | Lower upfront cost; higher operational expenses |

| Installation | Quick assembly with modular components | Lengthy installation process |

Introduction to Conveyor Systems

Conveyor systems are essential in material handling and manufacturing, facilitating efficient movement of goods. Modular conveyors offer flexibility with easily reconfigurable components, allowing adaptation to changing production needs. Traditional conveyors provide durable, fixed-path transport solutions ideal for steady, high-volume workflows that require minimal adjustment.

What Are Modular Conveyors?

Modular conveyors consist of interlocking plastic or metal components that create a customizable, flexible conveyor system ideal for varying product sizes and production layouts. Unlike traditional conveyors, which are often made from continuous belts or rollers, modular conveyors offer easy maintenance, quick assembly, and adaptability for complex manufacturing environments. Their segmented design improves durability and reduces downtime by allowing individual modules to be replaced without disassembling the entire conveyor.

What Are Traditional Conveyors?

Traditional conveyors consist of belt or roller systems designed to transport materials continuously along a fixed path, commonly used in manufacturing and packaging industries. These conveyors typically feature a rigid frame and require specific engineering to fit the production line layout, resulting in less flexibility compared to modular conveyors. Understanding your application needs helps determine if the durability and simplicity of traditional conveyors meet your material handling requirements.

Design Flexibility: Modular vs Traditional

Modular conveyors offer superior design flexibility compared to traditional conveyors by allowing easy reconfiguration, expansion, and customization to accommodate changing production needs. Traditional conveyors typically have fixed designs, limiting adaptability and requiring significant effort or cost for modifications. Your operations benefit from modular systems by quickly adjusting layouts and optimizing workflow without major downtime.

Installation and Setup Comparison

Modular conveyors offer faster installation and easier setup with their pre-engineered, customizable components that snap together without specialized tools, reducing downtime and labor costs. Traditional conveyors typically require more complex assembly, precise alignment, and specialized labor, leading to longer setup times and increased installation expenses. Your choice between modular and traditional conveyors can significantly impact project timelines and operational efficiency based on installation requirements.

Maintenance and Downtime Analysis

Modular conveyors require less maintenance than traditional conveyors due to their flexible design with easily replaceable components, minimizing downtime and repair costs. Traditional conveyors often involve longer maintenance times and higher expenses because of their complex assemblies and custom parts, increasing your operational interruptions. Optimizing conveyor systems by choosing modular designs can significantly improve maintenance efficiency and reduce overall downtime.

Cost Efficiency and ROI

Modular conveyors offer significant cost efficiency through lower maintenance expenses and reduced downtime compared to traditional conveyors, thanks to their easy-to-replace components and scalable design. The initial investment in modular conveyor systems is often balanced by faster installation times and enhanced adaptability, leading to a higher return on investment (ROI) in dynamic manufacturing environments. Traditional conveyors may have a lower upfront cost but typically incur higher long-term maintenance and upgrade expenses, which can diminish overall ROI.

Scalability and Expansion

Modular conveyors offer superior scalability compared to traditional conveyors, allowing seamless expansion by adding or rearranging modules to fit evolving production needs. Traditional conveyors often require extensive customization or replacement to accommodate growth, increasing downtime and costs. Your operations benefit from modular systems by enhancing flexibility and reducing time and expense during scalability or layout changes.

Application Suitability

Modular conveyors excel in applications requiring flexibility, easy maintenance, and quick reconfiguration, making them ideal for industries like food processing, packaging, and manufacturing with frequent product changes. Traditional conveyors offer robust durability and high load capacity, better suited for continuous, heavy-duty operations such as mining, automotive, and warehousing. Your choice depends on the need for adaptability versus handling heavy, consistent loads.

Choosing the Right Conveyor for Your Needs

Selecting the right conveyor system depends on factors such as load type, facility layout, and scalability requirements. Modular conveyors offer flexibility with easy reconfiguration, ideal for dynamic production lines, while traditional conveyors provide robustness and cost-efficiency for fixed operations. Evaluating operational demands and future growth plans ensures optimal performance and return on investment.

Modular Conveyor vs Traditional Conveyor Infographic

libmatt.com

libmatt.com