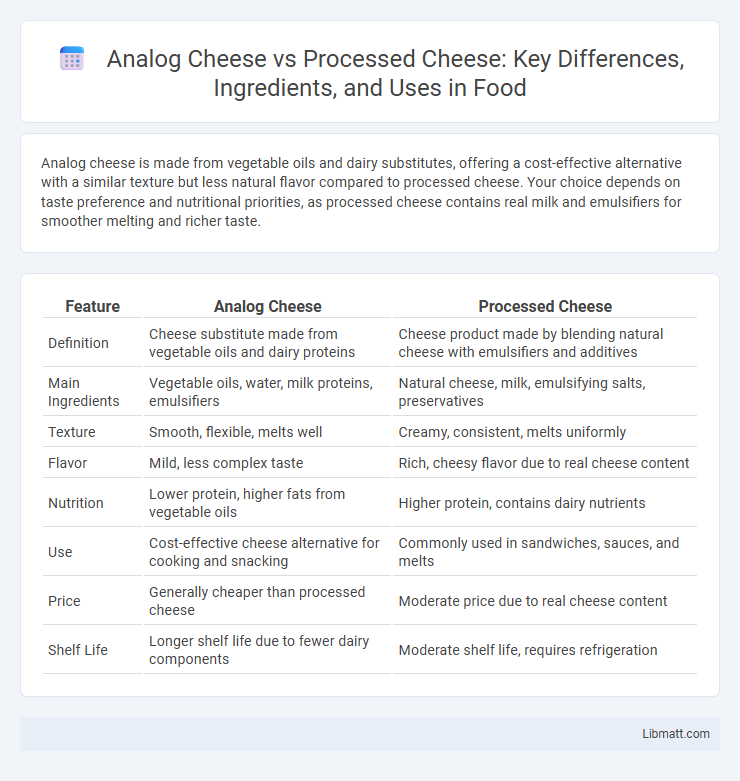

Analog cheese is made from vegetable oils and dairy substitutes, offering a cost-effective alternative with a similar texture but less natural flavor compared to processed cheese. Your choice depends on taste preference and nutritional priorities, as processed cheese contains real milk and emulsifiers for smoother melting and richer taste.

Table of Comparison

| Feature | Analog Cheese | Processed Cheese |

|---|---|---|

| Definition | Cheese substitute made from vegetable oils and dairy proteins | Cheese product made by blending natural cheese with emulsifiers and additives |

| Main Ingredients | Vegetable oils, water, milk proteins, emulsifiers | Natural cheese, milk, emulsifying salts, preservatives |

| Texture | Smooth, flexible, melts well | Creamy, consistent, melts uniformly |

| Flavor | Mild, less complex taste | Rich, cheesy flavor due to real cheese content |

| Nutrition | Lower protein, higher fats from vegetable oils | Higher protein, contains dairy nutrients |

| Use | Cost-effective cheese alternative for cooking and snacking | Commonly used in sandwiches, sauces, and melts |

| Price | Generally cheaper than processed cheese | Moderate price due to real cheese content |

| Shelf Life | Longer shelf life due to fewer dairy components | Moderate shelf life, requires refrigeration |

Understanding Analog Cheese: Definition and Composition

Analog cheese is a dairy product designed to mimic traditional cheese but is made using non-dairy fats, proteins, and emulsifiers instead of natural milk components. Its composition often includes vegetable oils, casein, and various additives to replicate the texture and flavor of real cheese while reducing production costs. Understanding this helps you differentiate between authentic cheese and analog alternatives commonly found in processed foods.

What Is Processed Cheese? Key Ingredients Explained

Processed cheese is a product made by blending natural cheeses with emulsifiers, milk solids, salts, and preservatives to create a consistent texture and extended shelf life. Key ingredients include cheddar or other cheese varieties, sodium citrate or phosphate as emulsifying agents, and sometimes food coloring and additional flavorings. This combination results in a smooth, meltable cheese ideal for food manufacturing and convenience products.

The Manufacturing Process: Analog vs Processed Cheese

The manufacturing process of analog cheese involves substituting traditional dairy ingredients with plant-based oils, milk protein concentrates, and starches to mimic natural cheese, resulting in a product designed for cost efficiency and extended shelf life. Processed cheese is created by blending natural cheese with emulsifiers, preservatives, and additional milk solids, then heating the mixture to achieve a smooth, uniform texture that melts consistently. Understanding these differences in production helps you choose products based on nutritional content, texture preferences, and dietary needs.

Taste and Texture Comparison

Analog cheese typically offers a milder, less complex flavor and a rubbery texture compared to authentic varieties, while processed cheese delivers a consistently smooth, creamy texture with a slightly salty taste due to added emulsifiers and preservatives. The taste of processed cheese is often uniform and less nuanced, making it popular for melting in sandwiches and sauces, whereas analog cheese may lack the rich, buttery notes found in traditional cheese but can vary depending on its base ingredients. Your preference for taste and texture will depend on whether you prioritize the smooth meltability of processed cheese or the economical, albeit less flavorful, qualities of analog cheese.

Nutritional Differences: Health Implications

Analog cheese generally contains lower protein and calcium levels compared to processed cheese, which often incorporates real dairy ingredients enhancing nutritional value. Processed cheese offers higher amounts of essential nutrients like calcium and vitamin D, supporting bone health more effectively than analog cheese. Health implications include a higher sodium content and artificial additives in analog cheese, potentially increasing risks of hypertension and allergic reactions versus the relatively balanced nutrient profile of processed cheese.

Common Uses in Cooking and Food Industry

Analog cheese is widely used in industrial food production for pizzas, sandwiches, and ready-to-eat meals due to its cost-effectiveness and longer shelf life. Processed cheese, favored for its melting properties and consistent texture, is commonly found in fast food items, cheese sauces, and snack products. Both types serve distinct purposes in cooking, with analog cheese preferred for bulk applications and processed cheese chosen for enhanced flavor and smoothness.

Labeling and Regulatory Considerations

Analog cheese is labeled as a cheese substitute and must comply with specific FDA standards for identity and ingredient composition, often highlighting the use of non-dairy fats and proteins. Processed cheese is regulated under FDA standards as a cheese product, requiring specific moisture and fat content levels, and must list all ingredients including emulsifiers and preservatives on the label. Labeling accuracy is critical to avoid consumer confusion and ensure compliance with food safety regulations and marketing laws.

Consumer Preferences and Market Trends

Consumer preferences increasingly favor natural analog cheese for its perceived authenticity and better nutritional profile compared to processed cheese, which is often viewed as less healthy due to additives. Market trends indicate a growing demand for specialty and artisanal analog cheese varieties, driven by health-conscious and gourmet consumers seeking quality ingredients. Your choice between analog and processed cheese can significantly impact taste experience and dietary goals as these preferences shape product availability and innovation in the cheese market.

Environmental Impact of Production

Analog cheese production generally has a lower environmental impact than processed cheese due to its simplified ingredient list and reduced reliance on dairy, which lowers greenhouse gas emissions and water usage. Processed cheese often involves more energy-intensive manufacturing processes and additional additives that increase its ecological footprint. Choosing analog cheese can help reduce your carbon footprint while supporting more sustainable food production practices.

Choosing the Right Cheese: Factors to Consider

When choosing between analog cheese and processed cheese, consider factors such as taste preference, nutritional content, and intended use in recipes. Analog cheese often contains plant-based fats and fillers, making it lower in protein but sometimes more affordable, while processed cheese blends natural cheese with emulsifiers for a consistent texture and meltability. Your decision should balance flavor authenticity, dietary needs, and cooking performance to achieve the best culinary results.

analog cheese vs processed cheese Infographic

libmatt.com

libmatt.com