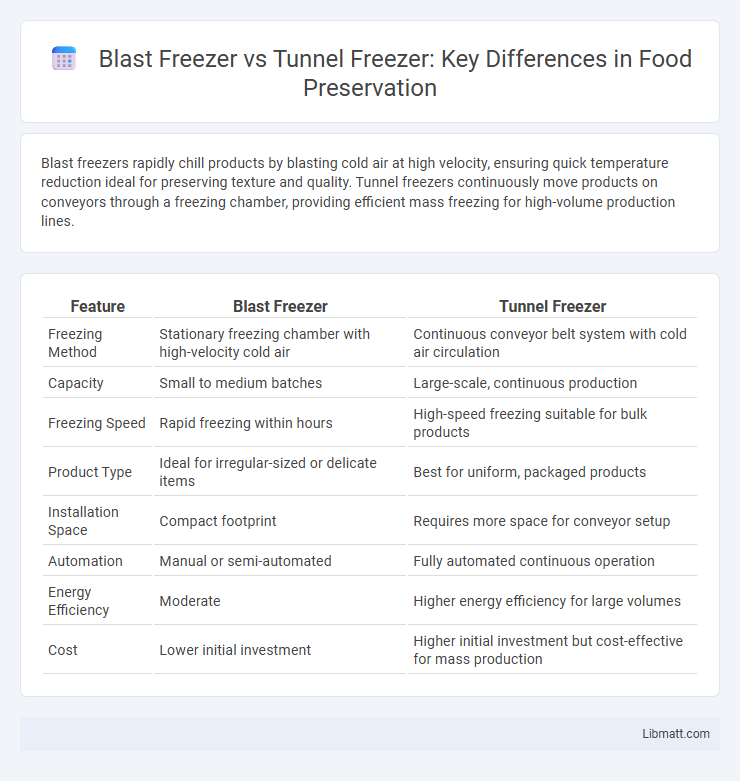

Blast freezers rapidly chill products by blasting cold air at high velocity, ensuring quick temperature reduction ideal for preserving texture and quality. Tunnel freezers continuously move products on conveyors through a freezing chamber, providing efficient mass freezing for high-volume production lines.

Table of Comparison

| Feature | Blast Freezer | Tunnel Freezer |

|---|---|---|

| Freezing Method | Stationary freezing chamber with high-velocity cold air | Continuous conveyor belt system with cold air circulation |

| Capacity | Small to medium batches | Large-scale, continuous production |

| Freezing Speed | Rapid freezing within hours | High-speed freezing suitable for bulk products |

| Product Type | Ideal for irregular-sized or delicate items | Best for uniform, packaged products |

| Installation Space | Compact footprint | Requires more space for conveyor setup |

| Automation | Manual or semi-automated | Fully automated continuous operation |

| Energy Efficiency | Moderate | Higher energy efficiency for large volumes |

| Cost | Lower initial investment | Higher initial investment but cost-effective for mass production |

Introduction to Blast Freezers and Tunnel Freezers

Blast freezers rapidly reduce the temperature of products by circulating extremely cold air around them, preserving quality and extending shelf life, making them ideal for individual or batch freezing processes. Tunnel freezers use a continuous conveyor system to freeze large volumes of food efficiently, optimizing production lines for uniform freezing and high throughput. Both methods maintain product integrity through rapid temperature reduction but differ in scale and application, with blast freezers suited for smaller batches and tunnel freezers for mass production.

How Blast Freezers Work

Blast freezers rapidly reduce the temperature of products by circulating extremely cold air at high velocity around the items, typically reaching temperatures between -30degC to -40degC. This process freezes the food quickly, minimizing ice crystal formation and preserving texture, taste, and nutritional value. The high-powered fans in blast freezers ensure uniform freezing, making them ideal for a wide range of perishable goods in the food industry.

How Tunnel Freezers Operate

Tunnel freezers operate by continuously moving products on a conveyor through a long, refrigerated tunnel where powerful fans circulate cold air at high velocities to rapidly reduce the temperature. This process ensures uniform freezing by maintaining consistent airflow and temperature, which enhances product quality and extends shelf life. Tunnel freezers are ideal for high-volume production lines requiring efficient, continuous freezing of packaged or bulk food items.

Key Differences Between Blast and Tunnel Freezers

Blast freezers rapidly cool products using high-velocity cold air in a stationary chamber, ideal for small batches or varied product sizes, while tunnel freezers continuously move products through a conveyor system for high-volume freezing. Blast freezers maintain consistent air temperature and velocity around each item, ensuring uniform freezing, whereas tunnel freezers prioritize throughput and efficiency with continuous processing. Understanding these key differences helps you select the optimal freezing method based on production scale, product type, and desired freezing speed.

Freezing Efficiency and Speed Comparison

Blast freezers achieve rapid freezing by circulating extremely cold air at high velocity around products, ensuring uniform temperature drop and minimizing ice crystal formation. Tunnel freezers convey items on a moving belt through a long, temperature-controlled chamber, optimizing continuous high-volume processing with consistent freezing speed. Your choice between blast and tunnel freezers depends on required freezing efficiency, speed, product type, and production scale to maintain quality and reduce freezing time effectively.

Space and Installation Requirements

Blast freezers typically require more vertical space due to their tall, cabinet-style design, making them suitable for facilities with limited floor area but ample height. Tunnel freezers demand larger floor space and complex installation with conveyors, ideal for high-volume production lines needing continuous freezing. Your choice depends on available space and production scale, with blast freezers fitting smaller operations and tunnel freezers accommodating extensive output.

Energy Consumption and Costs

Blast freezers generally consume less energy compared to tunnel freezers due to their compartmentalized design allowing for targeted cooling and reduced air leakage. Tunnel freezers require continuous operation of conveyor belts and high airflow rates, leading to higher electricity costs and increased wear on mechanical parts. Evaluating energy consumption per unit of product cooled reveals blast freezers offer better cost-efficiency in energy usage for smaller to medium batch freezing operations.

Food Quality and Product Versatility

Blast freezers maintain superior food quality by rapidly lowering temperatures, minimizing ice crystal formation that preserves texture and flavor in a wide range of products. Tunnel freezers offer exceptional product versatility, handling large volumes with continuous freezing suitable for items of varying sizes and shapes without compromising efficiency. Your choice depends on prioritizing optimal food quality for delicate products or maximizing throughput with diverse frozen goods.

Maintenance and Operational Considerations

Blast freezers require frequent maintenance of refrigeration coils and fans to ensure consistent airflow and temperature control, while tunnel freezers demand regular inspection of conveyor systems and tunnel seals to avoid product contamination and heat leakage. Operationally, blast freezers offer greater flexibility for varied batch sizes, whereas tunnel freezers excel in continuous, high-volume freezing processes but may require more energy for maintaining uniform freezing conditions. Your choice should consider the ease of routine maintenance and the operational scale to optimize productivity and equipment longevity.

Choosing the Right Freezing Solution for Your Business

Blast freezers rapidly reduce product temperature by circulating extremely cold air at high velocity, ideal for preserving quality and texture in individual items. Tunnel freezers provide a continuous freezing process suitable for high-volume production lines, using conveyor belts to efficiently freeze large batches. Selecting the right freezing solution depends on your product type, production capacity, and space constraints to maximize efficiency and maintain product integrity.

blast freezer vs tunnel freezer Infographic

libmatt.com

libmatt.com