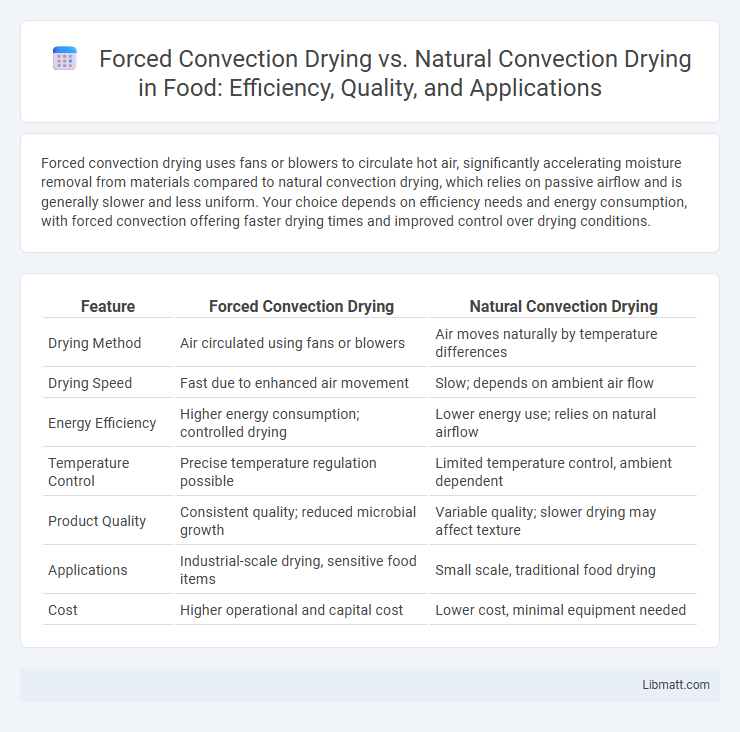

Forced convection drying uses fans or blowers to circulate hot air, significantly accelerating moisture removal from materials compared to natural convection drying, which relies on passive airflow and is generally slower and less uniform. Your choice depends on efficiency needs and energy consumption, with forced convection offering faster drying times and improved control over drying conditions.

Table of Comparison

| Feature | Forced Convection Drying | Natural Convection Drying |

|---|---|---|

| Drying Method | Air circulated using fans or blowers | Air moves naturally by temperature differences |

| Drying Speed | Fast due to enhanced air movement | Slow; depends on ambient air flow |

| Energy Efficiency | Higher energy consumption; controlled drying | Lower energy use; relies on natural airflow |

| Temperature Control | Precise temperature regulation possible | Limited temperature control, ambient dependent |

| Product Quality | Consistent quality; reduced microbial growth | Variable quality; slower drying may affect texture |

| Applications | Industrial-scale drying, sensitive food items | Small scale, traditional food drying |

| Cost | Higher operational and capital cost | Lower cost, minimal equipment needed |

Introduction to Convection Drying Methods

Forced convection drying uses external means like fans or blowers to enhance air movement, significantly accelerating moisture removal from materials. Natural convection drying relies on passive airflow induced by temperature differences, resulting in slower drying rates but lower energy consumption. The efficiency of forced convection drying makes it ideal for industrial applications requiring rapid drying, while natural convection is suited for low-cost, less time-sensitive processes.

Basics of Forced Convection Drying

Forced convection drying involves the use of external mechanical means, such as fans or blowers, to circulate heated air over the material being dried, significantly enhancing heat and mass transfer rates compared to natural convection drying. This method increases the drying rate by maintaining a higher temperature gradient and reducing the boundary layer thickness around the drying surface, leading to faster moisture removal. The efficiency of forced convection drying depends on factors such as air velocity, temperature, humidity, and the properties of the material being dried.

Fundamentals of Natural Convection Drying

Natural convection drying relies on buoyancy-driven airflow generated by temperature differences between the material surface and surrounding air, facilitating moisture removal without external energy input. Heat transfer occurs primarily through conduction and free convection, resulting in slower drying rates compared to forced convection methods. This process is energy-efficient and suitable for heat-sensitive materials but is limited by environmental conditions and lower drying efficiency.

Key Differences Between Forced and Natural Convection Drying

Forced convection drying uses fans or blowers to circulate heated air over the material, significantly increasing the drying rate by enhancing heat and mass transfer. Natural convection drying relies on the natural buoyancy-driven airflow caused by temperature differences, resulting in slower and less uniform drying. Forced convection systems offer better control over drying parameters, making them more efficient for industrial applications compared to the passive and energy-efficient but slower natural convection method.

Efficiency Comparison: Forced vs. Natural Convection

Forced convection drying significantly enhances heat transfer rates by using fans or blowers to circulate air, resulting in higher drying efficiency compared to natural convection drying. Natural convection relies on buoyancy-driven airflow, which produces slower moisture removal and often leads to longer drying times and increased energy consumption. The improved airflow in forced convection drying reduces drying time by up to 50%, making it more suitable for industrial applications requiring consistent and rapid moisture elimination.

Impact on Product Quality and Uniformity

Forced convection drying enhances product quality and uniformity by providing consistent temperature and airflow, reducing drying time and minimizing the risk of uneven moisture content. Natural convection drying often results in slower, variable drying rates due to dependence on ambient air movement, leading to potential quality degradation and inconsistent product texture. Optimizing forced convection parameters ensures improved retention of nutrients, color, and texture compared to the more unpredictable natural convection drying process.

Energy Consumption and Cost Analysis

Forced convection drying consumes significantly less energy and reduces drying time compared to natural convection, leading to lower operational costs. The use of fans or blowers in forced convection enhances heat transfer efficiency, resulting in faster moisture removal and improved productivity. Your choice of drying method directly impacts energy expenses, with forced convection offering a cost-effective solution in industrial applications.

Suitable Applications for Forced Convection Drying

Forced convection drying is highly suitable for industrial applications requiring rapid moisture removal, such as drying pharmaceuticals, food products, and timber. The use of fans or blowers accelerates heat transfer, making it ideal for processes demanding uniform and efficient drying under controlled temperatures. Your production lines benefit from reduced drying times and enhanced energy efficiency compared to natural convection drying.

Best Uses for Natural Convection Drying

Natural convection drying is best suited for products that require gentle, uniform drying without the risk of mechanical damage, such as delicate herbs, fruits, and flowers. It is ideal for small-scale or low-cost operations where energy efficiency and simplicity take priority over speed. This method relies on ambient airflow and temperature, making it suitable for environments with controlled humidity and moderate temperature conditions.

Choosing the Right Drying Method for Your Needs

Forced convection drying offers faster moisture removal by using external fans to circulate hot air, making it ideal for industrial applications requiring speed and uniformity. Natural convection drying relies on passive air flow and ambient heat, suitable for small-scale or energy-efficient processes where drying time is less critical. Selecting the right drying method depends on factors like drying time, energy consumption, product sensitivity, and production scale to optimize efficiency and product quality.

forced convection drying vs natural convection drying Infographic

libmatt.com

libmatt.com