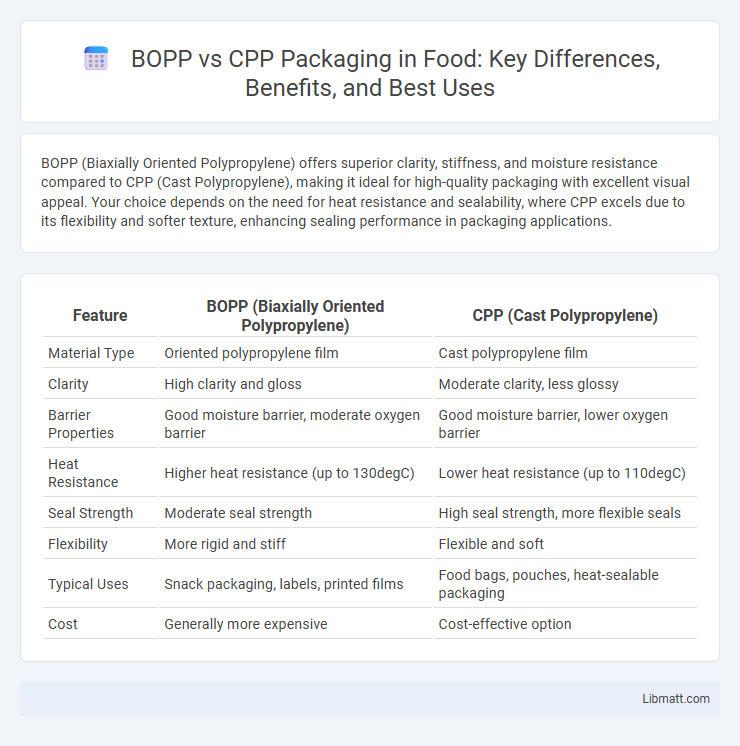

BOPP (Biaxially Oriented Polypropylene) offers superior clarity, stiffness, and moisture resistance compared to CPP (Cast Polypropylene), making it ideal for high-quality packaging with excellent visual appeal. Your choice depends on the need for heat resistance and sealability, where CPP excels due to its flexibility and softer texture, enhancing sealing performance in packaging applications.

Table of Comparison

| Feature | BOPP (Biaxially Oriented Polypropylene) | CPP (Cast Polypropylene) |

|---|---|---|

| Material Type | Oriented polypropylene film | Cast polypropylene film |

| Clarity | High clarity and gloss | Moderate clarity, less glossy |

| Barrier Properties | Good moisture barrier, moderate oxygen barrier | Good moisture barrier, lower oxygen barrier |

| Heat Resistance | Higher heat resistance (up to 130degC) | Lower heat resistance (up to 110degC) |

| Seal Strength | Moderate seal strength | High seal strength, more flexible seals |

| Flexibility | More rigid and stiff | Flexible and soft |

| Typical Uses | Snack packaging, labels, printed films | Food bags, pouches, heat-sealable packaging |

| Cost | Generally more expensive | Cost-effective option |

Introduction to BOPP and CPP Films

BOPP (Biaxially Oriented Polypropylene) and CPP (Cast Polypropylene) films are widely used in packaging for their durability and clarity. BOPP films offer exceptional tensile strength and moisture resistance, making them ideal for food packaging and labels. You can choose CPP films for their superior heat sealability and flexibility, which are essential for applications requiring airtight packaging and easy customization.

What is BOPP? Key Features and Applications

BOPP (Biaxially Oriented Polypropylene) is a versatile packaging film known for its excellent clarity, tensile strength, and moisture resistance, making it ideal for food packaging such as snack wrappers and confectionery. Key features include high gloss, superior printability, and excellent barrier properties against moisture and oxygen, ensuring product freshness. Your packaging benefits from BOPP's durability and lightweight nature, making it a popular choice in consumer goods and labeling applications.

What is CPP? Key Features and Applications

Cast polypropylene (CPP) is a transparent, flexible film made from polypropylene resin using a cast extrusion process, offering excellent clarity and heat resistance. Key features include superior sealing strength, high temperature tolerance up to 180degC, and excellent moisture and chemical resistance, making it ideal for packaging applications requiring durability and food safety. Your packaging solutions benefit from CPP's adaptability in heat sealing, lamination, and printing, commonly used in food packaging, medical products, and consumer goods.

Manufacturing Processes: BOPP vs CPP

BOPP (Biaxially Oriented Polypropylene) is manufactured through a process involving the extrusion of polypropylene film followed by simultaneous stretching in both machine and transverse directions, enhancing strength and clarity. CPP (Cast Polypropylene) production involves extruding molten polymer onto a chill roll surface, solidifying it through rapid cooling without orientation, resulting in a softer and more flexible film. Your choice between BOPP and CPP packaging materials depends on required properties like stiffness and heat resistance, which are directly influenced by their distinct manufacturing processes.

Thickness and Mechanical Properties Comparison

BOPP (Biaxially Oriented Polypropylene) films typically range from 12 to 50 microns in thickness, offering excellent tensile strength and high stiffness, making them ideal for applications requiring durability and clarity. CPP (Cast Polypropylene) films generally have a thickness range of 20 to 50 microns and exhibit superior impact resistance and elongation at break, contributing to enhanced flexibility and heat sealability in packaging. The mechanical properties of BOPP feature higher tensile strength and modulus, while CPP is favored for its toughness and better seal strength, influencing their selection based on packaging requirements.

Barrier Properties: Moisture and Gas Transmission

BOPP films offer superior moisture barrier properties with low water vapor transmission rates, making them ideal for protecting dry goods from humidity. CPP films provide better oxygen and gas barrier performance, essential for maintaining freshness in perishable food packaging. Combining BOPP and CPP layers in laminated films optimizes both moisture and gas resistance, enhancing overall package integrity and shelf life.

Optical and Surface Qualities

BOPP (Biaxially Oriented Polypropylene) films offer superior optical clarity and gloss compared to CPP (Cast Polypropylene), making them ideal for packaging where visual appeal is crucial. CPP films typically provide a smoother surface with better sealability and a softer texture but have lower transparency and gloss levels. Your packaging choice between BOPP and CPP depends on whether enhanced visual presentation or tactile surface properties are prioritized.

Cost and Economic Considerations

BOPP (Biaxially Oriented Polypropylene) typically offers a lower cost per unit due to its efficient production process and high tensile strength, making it economically favorable for high-volume packaging applications. CPP (Cast Polypropylene) often incurs higher material and processing costs but provides better clarity and a softer feel, which can justify its premium pricing for specialized or premium packaging. Your choice between BOPP and CPP will balance material cost, performance requirements, and the intended market positioning of the packaging.

Sustainability and Environmental Impact

BOPP (Biaxially Oriented Polypropylene) film offers superior recyclability compared to CPP (Cast Polypropylene), making it a more sustainable choice in packaging. BOPP's lower carbon footprint is attributed to its energy-efficient manufacturing process, while CPP typically requires higher energy inputs and generates more waste. Both materials are widely used, but ongoing advances in BOPP recycling technologies further enhance its environmental impact profile.

Choosing Between BOPP and CPP: Application Guidelines

BOPP (Biaxially Oriented Polypropylene) offers high tensile strength, excellent moisture barrier, and superior printability, making it ideal for food packaging and labels requiring durability and vibrant graphics. CPP (Cast Polypropylene) provides greater flexibility, heat resistance, and sealability, suited for applications like flow wrap packaging, heavy-duty bags, and lamination facing where formability and heat sealing are critical. Selecting between BOPP and CPP depends on specific requirements such as strength, clarity, heat resistance, and sealing needs to optimize packaging performance and product protection.

BOPP vs CPP (packaging) Infographic

libmatt.com

libmatt.com