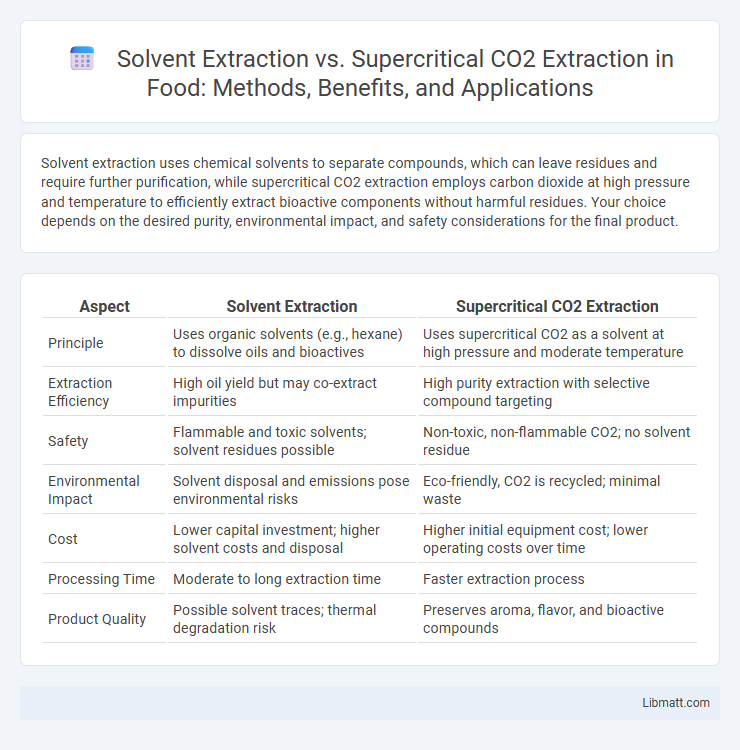

Solvent extraction uses chemical solvents to separate compounds, which can leave residues and require further purification, while supercritical CO2 extraction employs carbon dioxide at high pressure and temperature to efficiently extract bioactive components without harmful residues. Your choice depends on the desired purity, environmental impact, and safety considerations for the final product.

Table of Comparison

| Aspect | Solvent Extraction | Supercritical CO2 Extraction |

|---|---|---|

| Principle | Uses organic solvents (e.g., hexane) to dissolve oils and bioactives | Uses supercritical CO2 as a solvent at high pressure and moderate temperature |

| Extraction Efficiency | High oil yield but may co-extract impurities | High purity extraction with selective compound targeting |

| Safety | Flammable and toxic solvents; solvent residues possible | Non-toxic, non-flammable CO2; no solvent residue |

| Environmental Impact | Solvent disposal and emissions pose environmental risks | Eco-friendly, CO2 is recycled; minimal waste |

| Cost | Lower capital investment; higher solvent costs and disposal | Higher initial equipment cost; lower operating costs over time |

| Processing Time | Moderate to long extraction time | Faster extraction process |

| Product Quality | Possible solvent traces; thermal degradation risk | Preserves aroma, flavor, and bioactive compounds |

Introduction to Extraction Methods

Solvent extraction utilizes liquid solvents such as hexane or ethanol to dissolve target compounds from raw materials, offering high efficiency and cost-effectiveness in isolating essential oils, flavors, and pharmaceuticals. Supercritical CO2 extraction employs carbon dioxide above its critical temperature and pressure, creating a tunable solvent that provides selective extraction without toxic residues, ideal for heat-sensitive and high-purity applications. Both methods are widely used in food, cosmetic, and pharmaceutical industries but differ significantly in environmental impact, safety, and product quality.

Overview of Solvent Extraction

Solvent extraction utilizes organic solvents such as hexane, ethanol, or methanol to dissolve and separate target compounds from raw materials, making it a widely used method in industries like pharmaceuticals, food processing, and essential oil production. The process operates under relatively low pressure and temperature conditions, facilitating efficient extraction of bioactive compounds while preserving their integrity. Despite its effectiveness, solvent extraction poses challenges related to solvent residues, environmental impact, and the need for extensive solvent recovery systems.

Overview of Supercritical CO2 Extraction

Supercritical CO2 extraction utilizes carbon dioxide at elevated temperature and pressure to function as a solvent, efficiently separating desired compounds without leaving harmful residues. This method offers a green, non-toxic alternative to traditional solvent extraction, preserving the integrity and purity of sensitive bioactive compounds. Your products benefit from enhanced safety, environmental sustainability, and superior quality through this precise extraction technique.

Chemical Principles Behind Each Method

Solvent extraction relies on the differential solubility of compounds in an organic solvent, where the solvent selectively dissolves target compounds based on polarity and chemical affinity. Supercritical CO2 extraction utilizes carbon dioxide above its critical temperature and pressure, combining gas-like diffusivity with liquid-like density to penetrate materials and dissolve compounds without altering their chemical structure. Understanding these chemical principles helps you choose the most effective extraction method for preserving compound integrity and maximizing yield.

Efficiency and Yield Comparison

Supercritical CO2 extraction offers higher efficiency and purity compared to solvent extraction, as it selectively targets desired compounds without leaving harmful residues. Solvent extraction can yield larger quantities but often includes impurities requiring further refining, potentially lowering overall product quality. The yield from supercritical CO2 extraction is typically more consistent and environmentally friendly, making it preferable for high-value applications.

Purity and Product Quality

Supercritical CO2 extraction yields higher purity and superior product quality by avoiding residual solvents and preserving heat-sensitive compounds, resulting in a cleaner, more potent extract. Solvent extraction often leaves trace amounts of chemicals that can compromise the final product's purity and safety. Your choice influences the extract's overall quality, with supercritical CO2 offering a safer and more environmentally friendly alternative.

Environmental Impact and Sustainability

Solvent extraction often relies on organic solvents that can pose environmental hazards due to toxicity and volatile organic compound emissions, leading to higher ecological risks and disposal challenges. Supercritical CO2 extraction utilizes carbon dioxide, a non-toxic, non-flammable, and recyclable solvent, significantly reducing environmental impact and promoting sustainability through lower energy consumption and minimal chemical residues. Your choice of extraction method can greatly influence the environmental footprint and sustainability of the production process, with supercritical CO2 extraction generally offering a greener alternative.

Safety Considerations

Solvent extraction involves the use of flammable and potentially toxic chemicals, posing fire hazards and health risks through inhalation or skin contact. Supercritical CO2 extraction utilizes non-toxic carbon dioxide at high pressure, significantly reducing chemical residue and enhancing safety for both operators and consumers. Your choice should weigh the risk of chemical exposure in solvent extraction against the high-pressure equipment requirements of supercritical CO2 methods.

Cost and Industrial Scalability

Solvent extraction typically incurs lower initial equipment costs but involves higher expenses related to solvent recovery, disposal, and safety measures, impacting overall operational costs. Supercritical CO2 extraction demands significant upfront capital investment for specialized high-pressure equipment but offers cost savings through solvent recycling, minimal waste, and faster processing times, enhancing industrial scalability. Many large-scale industries prefer supercritical CO2 extraction for its efficiency and eco-friendly profile despite the higher initial cost, while solvent extraction remains popular in smaller operations due to lower entry barriers.

Applications and Best Use Cases

Solvent extraction is widely used in the food and pharmaceutical industries for extracting essential oils, flavors, and active compounds from plant materials due to its efficiency and versatility with various solvents. Supercritical CO2 extraction excels in producing high-purity extracts like cannabinoids, antioxidants, and fragrances, especially where solvent residues must be minimized, making it ideal for pharmaceutical, nutraceutical, and cosmetic applications. Best use cases for solvent extraction include large-scale, cost-sensitive operations requiring broad solvent compatibility, while supercritical CO2 extraction suits high-value, sensitive compounds demanding environmentally friendly and residue-free processing.

Solvent Extraction vs Supercritical CO2 Extraction Infographic

libmatt.com

libmatt.com