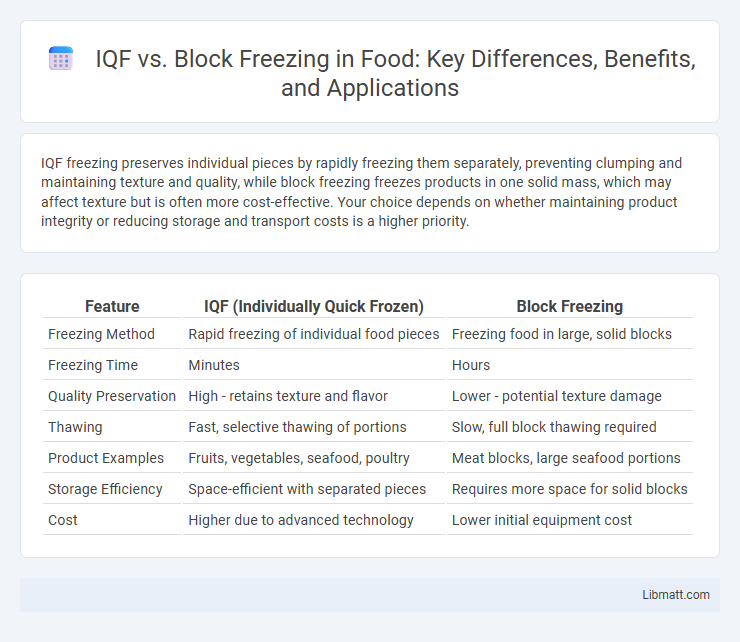

IQF freezing preserves individual pieces by rapidly freezing them separately, preventing clumping and maintaining texture and quality, while block freezing freezes products in one solid mass, which may affect texture but is often more cost-effective. Your choice depends on whether maintaining product integrity or reducing storage and transport costs is a higher priority.

Table of Comparison

| Feature | IQF (Individually Quick Frozen) | Block Freezing |

|---|---|---|

| Freezing Method | Rapid freezing of individual food pieces | Freezing food in large, solid blocks |

| Freezing Time | Minutes | Hours |

| Quality Preservation | High - retains texture and flavor | Lower - potential texture damage |

| Thawing | Fast, selective thawing of portions | Slow, full block thawing required |

| Product Examples | Fruits, vegetables, seafood, poultry | Meat blocks, large seafood portions |

| Storage Efficiency | Space-efficient with separated pieces | Requires more space for solid blocks |

| Cost | Higher due to advanced technology | Lower initial equipment cost |

Introduction to IQF and Block Freezing

Individual Quick Freezing (IQF) rapidly freezes individual food items separately, preserving texture and quality by preventing clumping, ideal for fruits, vegetables, and seafood. Block freezing involves freezing bulk quantities as a solid mass, which can result in longer thawing times and potential quality degradation due to slower freezing rates. IQF technology enhances product shelf life and maintains nutritional value better compared to traditional block freezing methods.

Understanding the IQF (Individual Quick Freezing) Process

IQF (Individual Quick Freezing) uses rapid freezing techniques that preserve the quality and texture of individual food pieces by freezing them separately, preventing clumping and maintaining freshness. This process involves exposing products to extremely cold air or liquid nitrogen at temperatures typically below -30degC, ensuring quick preservation of nutritional value and flavor. Compared to block freezing, which freezes food in solid blocks, IQF enhances product handling, portion control, and reduces thawing time.

What is Block Freezing?

Block freezing is a preservation method where products are frozen in large, solid masses, typically using mechanical freezers or blast chillers, resulting in a dense ice block around the food. This technique minimizes surface dehydration but often leads to longer thawing times and potential texture degradation due to slower freezing rates. Commonly used for bulky items like meats or fish, block freezing is less efficient than Individual Quick Freezing (IQF) in maintaining product quality and ease of handling.

Key Differences Between IQF and Block Freezing

IQF (Individually Quick Frozen) preserves the texture and quality of food by freezing items separately at extremely low temperatures, preventing clumping and allowing for convenient portion control. Block freezing involves freezing a large mass of food together, which can result in slower thaw times and potential quality degradation due to ice crystal formation. Understanding these key differences helps you choose the best freezing method to maintain freshness and optimize storage efficiency.

Benefits of IQF Freezing Technology

IQF freezing technology offers rapid freezing of individual food items, preserving texture, flavor, and nutritional value better than block freezing. This method prevents clumping, allowing you to easily separate portions, reducing waste and enhancing convenience in food preparation. IQF's precise freezing also minimizes ice crystal formation, resulting in superior product quality and longer shelf life.

Advantages of Block Freezing Methods

Block freezing methods provide superior preservation of texture and flavor in large cuts of meat and seafood by slowing the freezing process. This method reduces freezer burn and dehydration, maintaining product quality over extended storage periods. Your food retains more moisture and structural integrity compared to IQF, which is ideal for bulk storage and processing needs.

Applications: When to Use IQF vs Block Freezing

IQF (Individually Quick Frozen) is ideal for preserving the texture and quality of small, delicate food items like berries, shrimp, or vegetables, making it perfect for products that require quick portioning and minimal clumping. Block freezing suits larger quantities or bulk storage, such as meat cuts or fruits, where long-term preservation and space-efficient stacking are prioritized over individual piece separation. Your choice between IQF and block freezing should depend on your product's size, usage frequency, and handling requirements to maximize freshness and convenience.

Quality and Texture: Product Outcomes Compared

IQF (Individual Quick Freezing) maintains superior quality and texture by preventing large ice crystals, preserving cell structure and preventing drip loss upon thawing. Block freezing forms larger ice crystals that can rupture cells, resulting in a mushier texture and increased moisture loss. The distinct freezing processes of IQF ensure better retention of the product's original taste, appearance, and nutritional value compared to block freezing.

Cost Considerations: IQF vs Block Freezing

IQF (Individually Quick Frozen) technology typically incurs higher initial investment and operational costs compared to block freezing due to advanced machinery and greater energy consumption. Block freezing offers cost advantages in bulk freezing where lower equipment expenses and simpler logistics reduce overall expenditure. However, IQF's ability to maintain product quality and reduce waste can offset these costs, delivering better value in premium product segments.

Choosing the Right Freezing Method for Your Business

Choosing between IQF (Individually Quick Frozen) and block freezing depends on your product's quality preservation needs and storage efficiency. IQF maintains the individual texture and flavor of each item, making it ideal for businesses requiring rapid freezing and easy product separation. Block freezing offers cost-effective bulk storage but may compromise texture upon thawing, suitable for companies prioritizing volume over individual item quality.

IQF vs block freezing Infographic

libmatt.com

libmatt.com