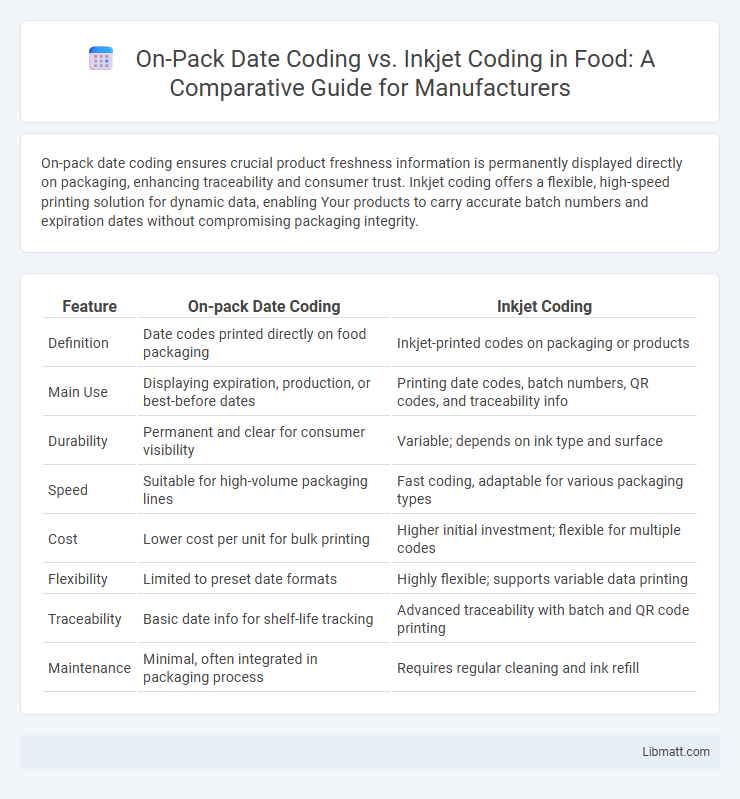

On-pack date coding ensures crucial product freshness information is permanently displayed directly on packaging, enhancing traceability and consumer trust. Inkjet coding offers a flexible, high-speed printing solution for dynamic data, enabling Your products to carry accurate batch numbers and expiration dates without compromising packaging integrity.

Table of Comparison

| Feature | On-pack Date Coding | Inkjet Coding |

|---|---|---|

| Definition | Date codes printed directly on food packaging | Inkjet-printed codes on packaging or products |

| Main Use | Displaying expiration, production, or best-before dates | Printing date codes, batch numbers, QR codes, and traceability info |

| Durability | Permanent and clear for consumer visibility | Variable; depends on ink type and surface |

| Speed | Suitable for high-volume packaging lines | Fast coding, adaptable for various packaging types |

| Cost | Lower cost per unit for bulk printing | Higher initial investment; flexible for multiple codes |

| Flexibility | Limited to preset date formats | Highly flexible; supports variable data printing |

| Traceability | Basic date info for shelf-life tracking | Advanced traceability with batch and QR code printing |

| Maintenance | Minimal, often integrated in packaging process | Requires regular cleaning and ink refill |

Introduction to On-pack Date Coding and Inkjet Coding

On-pack date coding involves printing production or expiry dates directly on packaging to ensure product traceability and compliance with regulatory standards. Inkjet coding uses precision ink droplets to mark variable data such as batch numbers and dates on various surfaces quickly and clearly. Understanding these technologies helps optimize Your packaging process for accuracy and efficiency in consumer information delivery.

Understanding On-pack Date Coding Technologies

On-pack date coding technologies encompass various methods for printing essential product information directly onto packaging, ensuring traceability and regulatory compliance. Inkjet coding, a common technique, uses high-speed jets of ink to create clear, precise dates on diverse surfaces, offering flexibility and minimal downtime. Understanding these technologies helps you select the most efficient and durable option for your production line, balancing cost, speed, and print quality.

What is Inkjet Coding?

Inkjet coding is a non-contact printing method that uses tiny droplets of ink to create variable information such as dates, batch numbers, or barcodes directly on product packaging. This technology offers high-speed application with minimal maintenance, making it ideal for coding on various surfaces including paper, plastic, and metal. Understanding inkjet coding helps you choose the most efficient date coding solution to ensure product traceability and compliance.

Key Differences Between On-pack and Inkjet Coding

On-pack date coding directly prints information such as expiry dates or batch numbers on product packaging, ensuring clear, permanent identification. Inkjet coding uses high-speed printers to apply variable data like dates or barcodes on products or packages, offering flexibility without altering packaging design. You should choose on-pack coding for durable, tamper-evident marks, while inkjet coding suits dynamic data and high-speed production lines.

Advantages of On-pack Date Coding

On-pack date coding offers superior traceability by directly printing expiration dates and batch numbers on individual product packaging, reducing the risk of mislabeling and improving inventory management. This method enhances consumer confidence by providing clear, legible information essential for product safety and regulatory compliance. You benefit from increased accuracy and durability in date coding, compared to the variable results often seen with inkjet coding.

Benefits of Inkjet Coding Solutions

Inkjet coding solutions offer high-speed, non-contact printing that ensures clear, durable codes on a variety of packaging materials without damaging the product. These systems provide greater flexibility by easily adapting to different packaging shapes, sizes, and surfaces, enabling efficient customization and on-demand coding. You benefit from reduced downtime and lower maintenance costs compared to on-pack date coding methods, resulting in improved productivity and cost savings.

Application Areas: On-pack vs. Inkjet Coding

On-pack date coding is commonly used for direct printing on product packaging such as cartons, bottles, and flexible pouches, ensuring clear visibility and tamper-evident information. Inkjet coding excels in marking on diverse surfaces including glass, metal, plastics, and non-porous materials, making it suitable for variable data printing in fast-paced production lines. Your choice depends on the packaging material and production speed, with on-pack coding ideal for primary packaging and inkjet coding favored for versatile, high-speed applications.

Cost Considerations and ROI

Inkjet coding generally offers lower upfront costs and faster setup times compared to on-pack date coding systems, making it a cost-effective solution for smaller production volumes or businesses with limited budgets. On-pack date coding systems, while typically requiring higher initial investments, deliver greater precision and durability for long-term applications, which can result in higher ROI through reduced rework and improved compliance. Evaluating your production scale and coding accuracy needs will help determine the best balance between cost and return on investment.

Factors to Consider When Choosing a Coding Method

Selecting between on-pack date coding and inkjet coding depends on factors such as packaging material compatibility, production line speed, and environmental conditions. On-pack date coding offers durability and precision on rigid surfaces, while inkjet coding provides flexibility and rapid application on various substrates. Cost-effectiveness, maintenance requirements, and desired print resolution also influence the optimal choice for specific manufacturing needs.

Future Trends in Packaging Date Coding Technologies

Future trends in packaging date coding technologies emphasize increased integration of IoT-enabled inkjet coding systems, enhancing real-time data tracking and quality control across supply chains. On-pack date coding is evolving with advanced laser coding techniques that offer higher resolution and permanence, reducing environmental impact from consumables. Smart date coding solutions are expected to incorporate AI-driven predictive maintenance and blockchain for improved traceability and fraud prevention in food and pharmaceutical packaging.

On-pack Date Coding vs Inkjet Coding Infographic

libmatt.com

libmatt.com