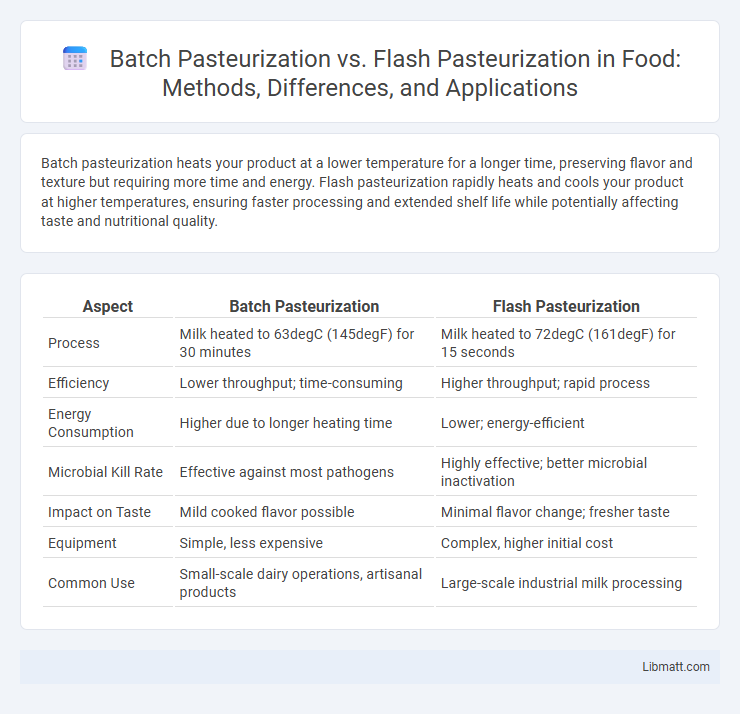

Batch pasteurization heats your product at a lower temperature for a longer time, preserving flavor and texture but requiring more time and energy. Flash pasteurization rapidly heats and cools your product at higher temperatures, ensuring faster processing and extended shelf life while potentially affecting taste and nutritional quality.

Table of Comparison

| Aspect | Batch Pasteurization | Flash Pasteurization |

|---|---|---|

| Process | Milk heated to 63degC (145degF) for 30 minutes | Milk heated to 72degC (161degF) for 15 seconds |

| Efficiency | Lower throughput; time-consuming | Higher throughput; rapid process |

| Energy Consumption | Higher due to longer heating time | Lower; energy-efficient |

| Microbial Kill Rate | Effective against most pathogens | Highly effective; better microbial inactivation |

| Impact on Taste | Mild cooked flavor possible | Minimal flavor change; fresher taste |

| Equipment | Simple, less expensive | Complex, higher initial cost |

| Common Use | Small-scale dairy operations, artisanal products | Large-scale industrial milk processing |

Introduction to Pasteurization Methods

Batch pasteurization involves heating a large volume of liquid at a controlled temperature for an extended period, typically 63degC for 30 minutes, effectively eliminating harmful microorganisms while preserving flavor. Flash pasteurization, also known as high-temperature short-time (HTST) pasteurization, rapidly heats the liquid to around 72degC for at least 15 seconds, ensuring quick microbial inactivation with minimal impact on taste and nutritional value. Your choice between these methods depends on the type of product, desired shelf life, and production scale.

What is Batch Pasteurization?

Batch pasteurization is a method of heating large volumes of liquid, such as milk or juice, to a specific temperature--typically 63degC (145degF)--for a set time, usually 30 minutes, to kill harmful microorganisms and extend shelf life. This process preserves the flavor and nutritional quality better than higher heat methods but requires more time and energy. Your choice of batch pasteurization may depend on product type, processing scale, and desired quality retention.

What is Flash Pasteurization?

Flash pasteurization, also known as high-temperature short-time (HTST) pasteurization, rapidly heats liquids to a temperature of about 71.5degC (160degF) for 15 to 30 seconds before quickly cooling them to remove harmful microorganisms while preserving taste and nutrients. This method contrasts with batch pasteurization, which heats liquids at lower temperatures, typically around 63degC (145degF), for 30 minutes, resulting in longer processing times. Flash pasteurization is widely used in the dairy and beverage industries for its efficiency and ability to maintain product quality.

Historical Overview of Pasteurization Techniques

Batch pasteurization, developed in the late 19th century, involves heating milk to around 63degC (145degF) for 30 minutes, representing the earliest method popularized by Louis Pasteur's work on microbial control. Flash pasteurization, introduced in the 20th century, rapidly heats milk to 72degC (161degF) for 15 seconds, significantly reducing processing time while maintaining product quality. Your choice between these methods depends on desired shelf life, flavor preservation, and processing efficiency.

Temperature and Time Differences

Batch pasteurization typically heats liquids to around 63degC (145degF) for 30 minutes, ensuring thorough microbial kill through extended exposure. Flash pasteurization rapidly raises the temperature to approximately 72degC (161degF) for just 15 seconds, balancing microbial safety with minimal impact on flavor and nutrients. Your choice depends on the product's sensitivity and shelf-life requirements, as flash pasteurization offers faster processing while batch pasteurization provides gentler heat treatment.

Impact on Nutritional Value and Flavor

Batch pasteurization, conducted at lower temperatures for longer times, better preserves heat-sensitive nutrients like vitamins C and B complex while maintaining a fuller, richer flavor profile. Flash pasteurization exposes products to higher temperatures for shorter durations, which can slightly degrade some nutrients but results in a cleaner taste by reducing microbial load rapidly. Both methods balance safety and quality, with batch pasteurization favoring nutrient retention and flash pasteurization optimizing flavor clarity and shelf life.

Microbial Reduction and Safety

Batch pasteurization offers effective microbial reduction by maintaining milk at a consistent temperature of around 63degC (145degF) for 30 minutes, ensuring the destruction of most pathogenic bacteria. Flash pasteurization, or High-Temperature Short-Time (HTST) pasteurization, rapidly heats milk to 72degC (161degF) for 15 seconds, achieving superior microbial kill rates and enhanced safety by minimizing heat exposure and preserving quality. Your choice between these methods influences the balance between microbial safety and nutrient retention, with flash pasteurization providing a faster, more efficient reduction of harmful microorganisms.

Industrial Applications and Scalability

Batch pasteurization suits small to medium-scale industrial applications where precise temperature control ensures uniform microbial reduction, ideal for artisanal products and dairy farms. Flash pasteurization supports high-volume processing with rapid heating and cooling cycles, making it highly scalable for large beverage manufacturers and liquid food production lines. Industrial adoption favors flash pasteurization for continuous operation efficiency, while batch methods allow flexibility for niche markets demanding tailored thermal treatments.

Cost Comparison and Energy Efficiency

Batch pasteurization generally incurs higher labor and operational costs due to longer processing times and manual handling requirements, whereas flash pasteurization benefits from automated systems that reduce labor expenses despite higher initial equipment investments. Energy efficiency favors flash pasteurization as it rapidly heats and cools products, minimizing energy consumption per unit compared to the prolonged heating cycles in batch processing. The overall cost-effectiveness of flash pasteurization improves with large-scale production, while batch pasteurization may remain viable for smaller volumes despite lower energy efficiency.

Choosing the Right Pasteurization Method

Batch pasteurization offers precise temperature control and is ideal for small-scale production, preserving flavor and nutrients through slower heating. Flash pasteurization, with rapid heating and cooling at higher temperatures, suits large-scale operations by ensuring longer shelf life and microbial safety. Selecting the right pasteurization method depends on production volume, product type, and desired quality outcomes.

Batch Pasteurization vs Flash Pasteurization Infographic

libmatt.com

libmatt.com