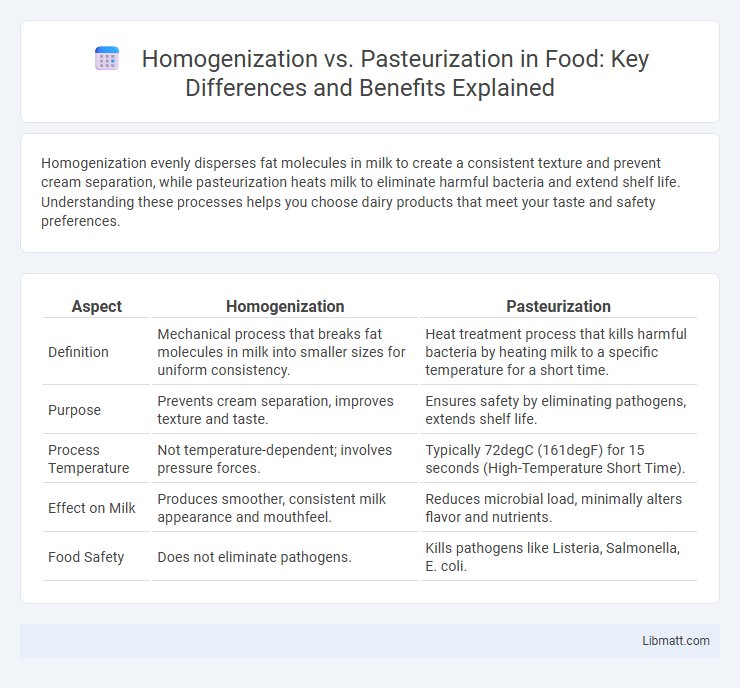

Homogenization evenly disperses fat molecules in milk to create a consistent texture and prevent cream separation, while pasteurization heats milk to eliminate harmful bacteria and extend shelf life. Understanding these processes helps you choose dairy products that meet your taste and safety preferences.

Table of Comparison

| Aspect | Homogenization | Pasteurization |

|---|---|---|

| Definition | Mechanical process that breaks fat molecules in milk into smaller sizes for uniform consistency. | Heat treatment process that kills harmful bacteria by heating milk to a specific temperature for a short time. |

| Purpose | Prevents cream separation, improves texture and taste. | Ensures safety by eliminating pathogens, extends shelf life. |

| Process Temperature | Not temperature-dependent; involves pressure forces. | Typically 72degC (161degF) for 15 seconds (High-Temperature Short Time). |

| Effect on Milk | Produces smoother, consistent milk appearance and mouthfeel. | Reduces microbial load, minimally alters flavor and nutrients. |

| Food Safety | Does not eliminate pathogens. | Kills pathogens like Listeria, Salmonella, E. coli. |

Introduction to Homogenization and Pasteurization

Homogenization is a mechanical process that breaks down fat molecules in milk, creating a uniform and stable mixture by preventing cream separation. Pasteurization involves heating milk to specific temperatures to eliminate harmful bacteria while preserving nutritional quality and extending shelf life. Understanding both processes helps you choose dairy products that meet your safety and texture preferences.

Defining Homogenization: Process and Purpose

Homogenization is a mechanical process that breaks down fat molecules in milk, ensuring a uniform distribution and preventing cream from separating. This process improves the milk's texture and taste by creating a smoother, consistent product. Your milk remains fresh and visually appealing due to the even dispersion of fat achieved through homogenization.

Understanding Pasteurization: Process and Purpose

Pasteurization involves heating milk to a specific temperature for a set time to kill harmful bacteria without altering its nutritional value, ensuring safety and extending shelf life. This process primarily targets pathogens like Listeria, Salmonella, and E. coli to protect your health. Understanding pasteurization helps in recognizing why milk labeled as "pasteurized" is safer for consumption compared to raw milk.

Key Differences Between Homogenization and Pasteurization

Homogenization mechanically breaks down fat globules in milk to create a uniform texture, while pasteurization uses heat treatment to kill harmful bacteria and extend shelf life. Your milk undergoes homogenization to prevent cream separation, whereas pasteurization ensures safety by reducing pathogens without altering flavor significantly. Understanding these key differences helps in selecting dairy products based on texture preference and health considerations.

Benefits of Homogenization in Dairy Processing

Homogenization improves the texture and taste of dairy products by evenly distributing fat globules, preventing cream separation and enhancing mouthfeel. This process increases the shelf life and stability of milk by reducing the size of fat particles, which also aids in better digestion and absorption of nutrients. Your dairy products will have a consistent quality and enriched flavor, making homogenization essential in modern dairy processing.

Health Advantages of Pasteurization

Pasteurization significantly reduces harmful bacteria and pathogens in milk, enhancing safety and minimizing the risk of foodborne illnesses. Unlike homogenization, which primarily improves texture and consistency, pasteurization directly protects your health by eliminating microbes such as Salmonella, Listeria, and E. coli. This process preserves essential nutrients while ensuring that dairy products remain safe for consumption.

Effects on Milk Flavor, Texture, and Shelf Life

Homogenization breaks down fat molecules in milk, creating a smoother texture and creamy flavor, while pasteurization uses heat to kill harmful bacteria, extending shelf life without significantly altering taste. Your milk will have a consistent texture due to homogenization, but pasteurization is essential for safety and longevity, slightly affecting flavor by reducing raw milk notes. Combining both processes results in milk that is safe, has a uniform texture, and stays fresh longer.

Common Misconceptions and Myths

Homogenization is often confused with pasteurization, but while homogenization mechanically breaks down fat molecules in milk to prevent separation, pasteurization uses heat to kill harmful bacteria. A common myth is that homogenized milk is less nutritious or causes allergies, despite scientific evidence showing it does not affect nutritional value or allergenic potential. Many also mistakenly believe pasteurization lowers milk quality, although it actually ensures safety by eliminating pathogens without significantly altering taste or nutrients.

Regulatory Standards and Safety Guidelines

Regulatory standards for homogenization and pasteurization are enforced by agencies such as the FDA and USDA to ensure dairy product safety and quality. Pasteurization must meet strict temperature and time protocols, typically 161degF for 15 seconds (HTST), to eliminate pathogenic bacteria, while homogenization standards focus on mechanical pressure levels, usually 2,000 to 4,000 psi, to achieve consistent fat dispersion. Safety guidelines require pasteurized products to have verified pathogen destruction through routine microbial testing, whereas homogenization emphasizes preventing fat separation and improving shelf life without altering safety profiles.

Choosing the Right Process for Your Dairy Products

Homogenization evenly distributes fat molecules in milk, enhancing texture and preventing cream separation, while pasteurization eliminates harmful bacteria through heat treatment, ensuring safety and extended shelf life. Selecting the right process depends on the desired product quality, with homogenization preferred for smooth consistency in milk and cream, and pasteurization essential for microbiological safety in all dairy products. Dairy producers must balance texture, flavor retention, and health standards to optimize their product's appeal and regulatory compliance.

Homogenization vs Pasteurization Infographic

libmatt.com

libmatt.com