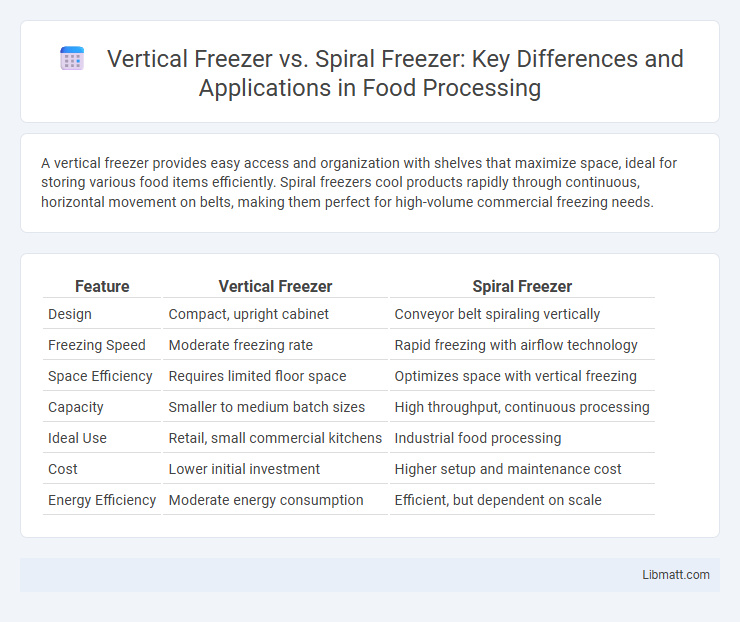

A vertical freezer provides easy access and organization with shelves that maximize space, ideal for storing various food items efficiently. Spiral freezers cool products rapidly through continuous, horizontal movement on belts, making them perfect for high-volume commercial freezing needs.

Table of Comparison

| Feature | Vertical Freezer | Spiral Freezer |

|---|---|---|

| Design | Compact, upright cabinet | Conveyor belt spiraling vertically |

| Freezing Speed | Moderate freezing rate | Rapid freezing with airflow technology |

| Space Efficiency | Requires limited floor space | Optimizes space with vertical freezing |

| Capacity | Smaller to medium batch sizes | High throughput, continuous processing |

| Ideal Use | Retail, small commercial kitchens | Industrial food processing |

| Cost | Lower initial investment | Higher setup and maintenance cost |

| Energy Efficiency | Moderate energy consumption | Efficient, but dependent on scale |

Introduction to Vertical and Spiral Freezers

Vertical freezers are compact, standing units ideal for small spaces and efficient food storage, featuring shelves or compartments accessible from the front. Spiral freezers use a continuous conveyor belt that winds in a spiral pattern, offering rapid freezing for high-volume food production and preserving product quality. Your choice between these two depends on storage capacity needs and processing speed requirements.

How Vertical Freezers Work

Vertical freezers operate by circulating cold air vertically through multiple compartments, using fans to maintain consistent temperatures and efficiently freeze food items stored on shelves or bins. This design leverages gravity to evenly distribute cold air, helping preserve texture and flavor while minimizing frost buildup. Your choice of a vertical freezer offers easy access and space-saving benefits, ideal for bulk storage in commercial or home environments.

How Spiral Freezers Operate

Spiral freezers operate by continuously moving food products along a spiral conveyor belt through a chilled chamber, allowing for rapid and uniform freezing. The vertical design maximizes space efficiency by stacking multiple layers of the belt in a compact footprint, optimizing freezing capacity per square meter. Forced air circulation inside the chamber enhances heat transfer, ensuring consistent product quality and faster freezing times compared to traditional vertical freezers.

Key Differences Between Vertical and Spiral Freezers

Vertical freezers feature a compact, upright design ideal for limited spaces, while spiral freezers employ a continuous belt system that maximizes freezing efficiency for large-volume production. The key difference lies in airflow and freezing speed, with spiral freezers providing rapid, uniform freezing through horizontal product movement and consistent cold air circulation, whereas vertical freezers rely on vertical air flow which may result in slower freezing times. Your choice depends on production capacity and space constraints, as spiral freezers suit high-demand industrial use, while vertical freezers serve smaller-scale or specialized freezing needs.

Space and Footprint Comparison

Vertical freezers feature a compact footprint ideal for limited kitchen space, offering easy access through upright doors and efficient storage with stacked shelves. Spiral freezers, while occupying a larger floor area due to their rotating, multi-tiered design, maximize freezing capacity by continuously processing large volumes of products. Your choice depends on balancing available space with freezing throughput requirements, where vertical freezers suit smaller operations and spiral freezers support high-capacity industrial needs.

Energy Efficiency and Cost Implications

Vertical freezers typically consume less energy due to better insulation and compartmentalized storage, reducing cold air loss during frequent door openings. Spiral freezers, designed for continuous high-volume freezing, require more energy but offer cost savings through faster processing times and improved product throughput. Evaluating operational scale and energy tariffs is essential to determine the most cost-effective choice between these freezer types.

Product Quality and Freezing Speed

Vertical freezers provide consistent product quality by ensuring even freezing through stationary airflow, preserving texture and taste effectively. Spiral freezers achieve superior freezing speed due to continuous conveyor movement and high airflow velocity, rapidly reducing product temperature for efficient processing. Your choice depends on balancing the need for faster freezing times with maintaining optimal product quality.

Maintenance and Operational Considerations

Vertical freezers require regular defrosting to prevent ice buildup, while spiral freezers demand continuous monitoring of belt tension and motor lubrication to ensure smooth operation. Maintenance costs for vertical freezers are generally lower due to simpler designs, whereas spiral freezers, with their automated systems, may incur higher expenses but offer greater energy efficiency. Operationally, spiral freezers provide faster freezing times ideal for high-volume production, whereas vertical freezers suit smaller-scale operations with less intensive freezing needs.

Industry Applications for Vertical vs Spiral Freezers

Vertical freezers are widely used in retail and small-scale food storage due to their compact design and easy product access, ideal for maintaining frozen goods in grocery stores and convenience outlets. Spiral freezers excel in high-capacity industrial food processing environments, efficiently freezing large volumes of items such as seafood, baked goods, and ready-to-eat meals with faster freezing times and better product quality preservation. Your choice depends on the scale and speed requirements of your food freezing operations, with vertical freezers suiting lower volumes and spiral freezers catering to continuous, high-throughput production lines.

Choosing the Right Freezer for Your Business

Choosing the right freezer for your business depends on product type, space availability, and freezing speed requirements; vertical freezers offer efficient use of vertical space and are ideal for storing packaged goods with easy access, while spiral freezers excel in continuous rapid freezing of products like baked goods and seafood due to their conveyor belt system. Vertical freezers are cost-effective for small to medium batches and provide easy inventory management, whereas spiral freezers handle high-volume production, maintaining product quality through consistent airflow and temperature control. Evaluating your production scale, loading frequency, and product sensitivity ensures optimal freezer selection, enhancing operational efficiency and preserving product integrity.

Vertical Freezer vs Spiral Freezer Infographic

libmatt.com

libmatt.com