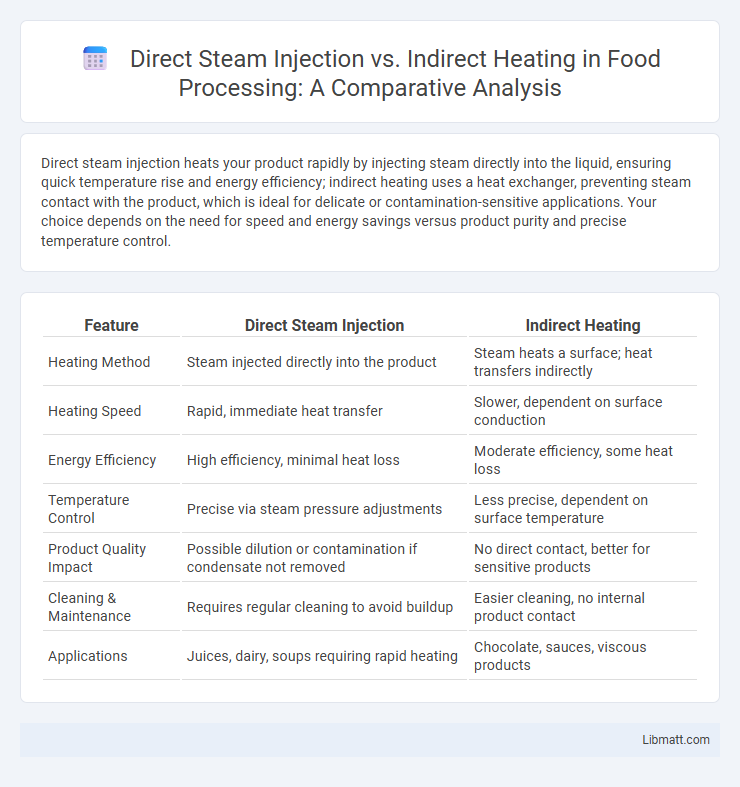

Direct steam injection heats your product rapidly by injecting steam directly into the liquid, ensuring quick temperature rise and energy efficiency; indirect heating uses a heat exchanger, preventing steam contact with the product, which is ideal for delicate or contamination-sensitive applications. Your choice depends on the need for speed and energy savings versus product purity and precise temperature control.

Table of Comparison

| Feature | Direct Steam Injection | Indirect Heating |

|---|---|---|

| Heating Method | Steam injected directly into the product | Steam heats a surface; heat transfers indirectly |

| Heating Speed | Rapid, immediate heat transfer | Slower, dependent on surface conduction |

| Energy Efficiency | High efficiency, minimal heat loss | Moderate efficiency, some heat loss |

| Temperature Control | Precise via steam pressure adjustments | Less precise, dependent on surface temperature |

| Product Quality Impact | Possible dilution or contamination if condensate not removed | No direct contact, better for sensitive products |

| Cleaning & Maintenance | Requires regular cleaning to avoid buildup | Easier cleaning, no internal product contact |

| Applications | Juices, dairy, soups requiring rapid heating | Chocolate, sauces, viscous products |

Introduction to Heating Technologies

Direct steam injection heats by injecting steam directly into liquids, providing rapid and uniform temperature increase with minimal heat loss. Indirect heating relies on heat exchangers or jackets, transferring heat without direct contact, ensuring product purity and reducing contamination risk. Your choice between these methods depends on factors like heating speed, energy efficiency, and process hygiene requirements.

Understanding Direct Steam Injection

Direct steam injection heats liquids rapidly by introducing steam directly into the product, ensuring immediate temperature rise and efficient energy transfer. This method offers precise temperature control and reduces processing time compared to indirect heating, which uses a heat exchanger to transfer steam heat without contact. Industries like food processing and chemical manufacturing favor direct steam injection for its higher thermal efficiency and reduced equipment footprint.

What Is Indirect Heating?

Indirect heating transfers heat to a substance without direct contact between the heating medium and the product, typically using a heat exchanger or jacketed vessel. This method prevents contamination and is ideal for heating sensitive materials or liquids that require precise temperature control. Your process benefits from enhanced safety and energy efficiency when using indirect heating systems.

Key Differences: Direct Steam Injection vs Indirect Heating

Direct steam injection transfers heat by injecting steam directly into the liquid, resulting in rapid and uniform heating with minimal heat loss, while indirect heating uses a heat exchanger to transfer steam heat without mixing fluids, ensuring product purity and controlled temperature. Direct steam injection offers higher energy efficiency and faster start-up times, but may require additional steps for condensate removal, whereas indirect heating provides safer operation for sensitive products due to no direct steam contact. Your choice depends on factors like processing speed, product sensitivity, and maintenance preferences.

Efficiency Comparison

Direct steam injection offers superior thermal efficiency by transferring heat directly through steam condensation, minimizing energy loss and enabling rapid temperature changes. Indirect heating relies on heat exchangers, which often result in reduced efficiency due to steam condensation within the exchanger and slower heat transfer rates. Studies indicate that direct steam injection can achieve efficiency levels up to 85-90%, compared to 70-80% for indirect heating systems.

Impact on Product Quality

Direct steam injection ensures rapid and uniform heating, minimizing thermal degradation and preserving the texture, flavor, and nutritional value of sensitive products. Indirect heating offers precise temperature control but may cause uneven heat distribution, potentially leading to longer processing times and quality inconsistencies. Both methods influence microbial safety, but direct steam injection often results in superior retention of product quality due to minimal heat exposure.

Energy Consumption Analysis

Direct steam injection systems deliver steam directly into the product, resulting in rapid heat transfer and higher energy efficiency due to minimal heat loss. Indirect heating relies on a heat exchanger, where steam transfers heat through a barrier, causing greater energy consumption from temperature gradients and longer heating times. Energy consumption analysis shows direct steam injection reduces operational costs by up to 30% compared to indirect heating methods in industrial processes.

Maintenance and Operational Costs

Direct steam injection systems generally have lower operational costs due to higher energy efficiency and faster heating times, but they require more frequent maintenance to address scaling and corrosion issues directly in the steam path. Indirect heating systems, while typically incurring higher energy consumption and longer heat-up periods, benefit from reduced maintenance costs since the steam does not contact the process fluid, minimizing fouling and extending equipment lifespan. Choosing between the two depends on balancing the higher upfront maintenance requirements of direct steam injection against the increased operational energy expenses associated with indirect heating.

Industry Applications and Use Cases

Direct steam injection (DSI) is widely used in food and beverage industries for rapid heating and precise temperature control, particularly in processes like pasteurization and sterilization where quick steam contact prevents product degradation. Indirect heating methods, such as heat exchangers, are preferred in chemical and pharmaceutical industries requiring contamination-free environments and consistent, controlled heating without direct steam exposure. Both heating techniques optimize thermal efficiency and product quality but are selected based on industry-specific requirements for hygiene, speed, and heat transfer precision.

Choosing the Right Heating Method

Choosing the right heating method involves evaluating energy efficiency, application requirements, and operational costs. Direct steam injection offers rapid, uniform heating with high thermal efficiency, ideal for food processing or sterilization but requires steam quality control to prevent contamination. Indirect heating provides cleaner heat transfer without direct steam contact, suitable for sensitive products or closed systems, though it may involve higher capital and maintenance costs.

Direct Steam Injection vs Indirect Heating Infographic

libmatt.com

libmatt.com