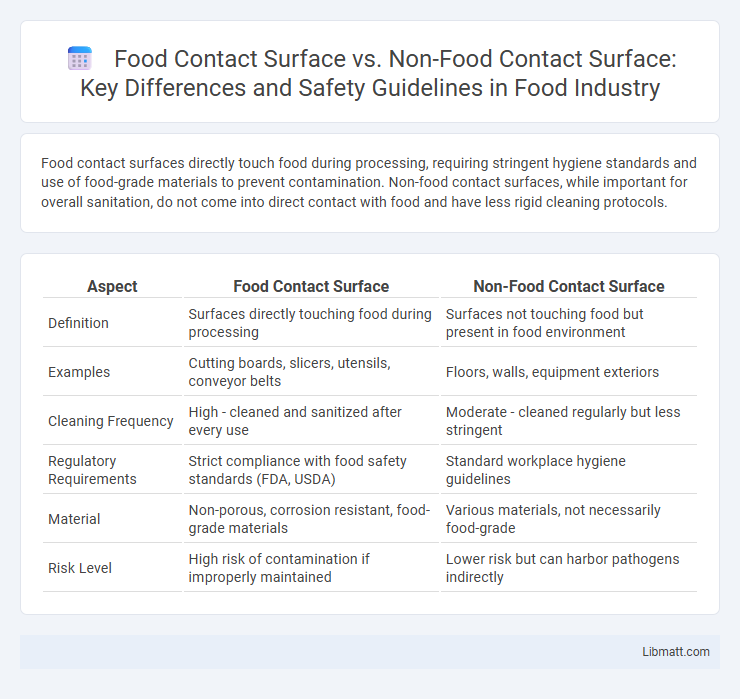

Food contact surfaces directly touch food during processing, requiring stringent hygiene standards and use of food-grade materials to prevent contamination. Non-food contact surfaces, while important for overall sanitation, do not come into direct contact with food and have less rigid cleaning protocols.

Table of Comparison

| Aspect | Food Contact Surface | Non-Food Contact Surface |

|---|---|---|

| Definition | Surfaces directly touching food during processing | Surfaces not touching food but present in food environment |

| Examples | Cutting boards, slicers, utensils, conveyor belts | Floors, walls, equipment exteriors |

| Cleaning Frequency | High - cleaned and sanitized after every use | Moderate - cleaned regularly but less stringent |

| Regulatory Requirements | Strict compliance with food safety standards (FDA, USDA) | Standard workplace hygiene guidelines |

| Material | Non-porous, corrosion resistant, food-grade materials | Various materials, not necessarily food-grade |

| Risk Level | High risk of contamination if improperly maintained | Lower risk but can harbor pathogens indirectly |

Definition of Food Contact Surfaces

Food contact surfaces refer to any parts of equipment or materials that directly touch food during processing, preparation, or storage, including utensils, cutting boards, conveyor belts, and packaging surfaces. These surfaces must comply with strict hygiene and safety standards to prevent contamination and ensure food safety. In contrast, non-food contact surfaces do not directly touch food but still require regular cleaning to maintain overall sanitation in food handling environments.

What Are Non-Food Contact Surfaces?

Non-food contact surfaces refer to areas in food processing environments that do not directly touch food during preparation, handling, or storage. These surfaces include walls, floors, ceilings, equipment exteriors, and conveyor frames, which can harbor contaminants if not properly cleaned and sanitized. Effective sanitation protocols targeting non-food contact surfaces are essential to prevent cross-contamination and ensure overall food safety compliance.

Key Differences Between Food and Non-Food Contact Surfaces

Food contact surfaces are specially designed and manufactured to ensure safety, hygiene, and compliance with regulatory standards such as FDA and EU regulations, preventing contamination and chemical migration into food products. Non-food contact surfaces do not have direct interaction with food and therefore have less stringent requirements regarding materials, cleanability, and contamination risks. The primary differences lie in material composition, surface smoothness, and certification, with food contact surfaces requiring FDA-approved, non-toxic, and corrosion-resistant materials to maintain food safety.

Regulatory Standards for Food Contact Surfaces

Regulatory standards for food contact surfaces require materials to be non-toxic, non-absorbent, and easily cleanable to prevent contamination and ensure food safety. Non-food contact surfaces are subject to less stringent regulations but must still meet basic hygiene standards to avoid indirect contamination. Your compliance with these standards helps maintain product quality and protects consumer health.

Common Materials Used for Food Contact Surfaces

Food contact surfaces commonly use materials such as stainless steel, food-grade plastics like polyethylene and polypropylene, and glass due to their non-reactive, easy-to-clean, and durable properties. These materials prevent contamination and ensure food safety by resisting corrosion, chemical leaching, and microbial growth. Your choice of food contact surface materials directly impacts hygiene standards and compliance with food safety regulations.

Examples of Non-Food Contact Surfaces in Food Facilities

Non-food contact surfaces in food facilities include walls, floors, ceilings, drains, support beams, and equipment exteriors that do not directly touch food products. These surfaces require regular cleaning to prevent contamination but do not need to meet the same strict sanitary standards as food contact surfaces. Ensuring your food facility maintains strict hygiene protocols on both food contact and non-food contact surfaces helps control cross-contamination risks and maintains overall safety.

Cleaning and Sanitizing Food Contact Surfaces

Food contact surfaces require stringent cleaning and sanitizing protocols to eliminate harmful bacteria, allergens, and residues that could contaminate your food. Non-food contact surfaces still need regular cleaning to prevent cross-contamination but do not demand the same level of sanitization as food contact surfaces. Proper use of food-safe sanitizers and verified cleaning procedures ensures the safety and hygiene of all food contact areas.

Risks Associated with Improper Surface Classification

Improper classification of food contact surfaces can lead to cross-contamination, posing significant health risks such as foodborne illnesses caused by pathogens like Salmonella and Listeria. Non-food contact surfaces harbor bacteria and allergens, which may transfer to food if surfaces are misclassified or inadequately cleaned, compromising food safety. Ensuring accurate surface classification helps you implement proper sanitation protocols, minimizing contamination risks and protecting consumer health.

Best Practices for Maintaining Food Contact Surfaces

Regular cleaning and sanitizing of food contact surfaces using approved food-grade chemicals prevent contamination and ensure food safety. Frequent inspection for cracks, corrosion, or buildup on stainless steel, plastic, and glass surfaces helps maintain hygiene standards. Implementing strict protocols for avoiding cross-contamination between food contact and non-food contact surfaces is essential in food processing environments.

Importance of Surface Distinction in Food Safety

Proper distinction between food contact surfaces (FCS) and non-food contact surfaces (NFCS) is critical for preventing cross-contamination and ensuring food safety. Food contact surfaces, such as cutting boards and conveyor belts, require stringent hygiene and sanitation standards because they directly interact with food. Non-food contact surfaces, including walls and floors, although less critical, must also be monitored to maintain an overall sanitary environment and reduce microbial risks.

food contact surface vs non-food contact surface Infographic

libmatt.com

libmatt.com