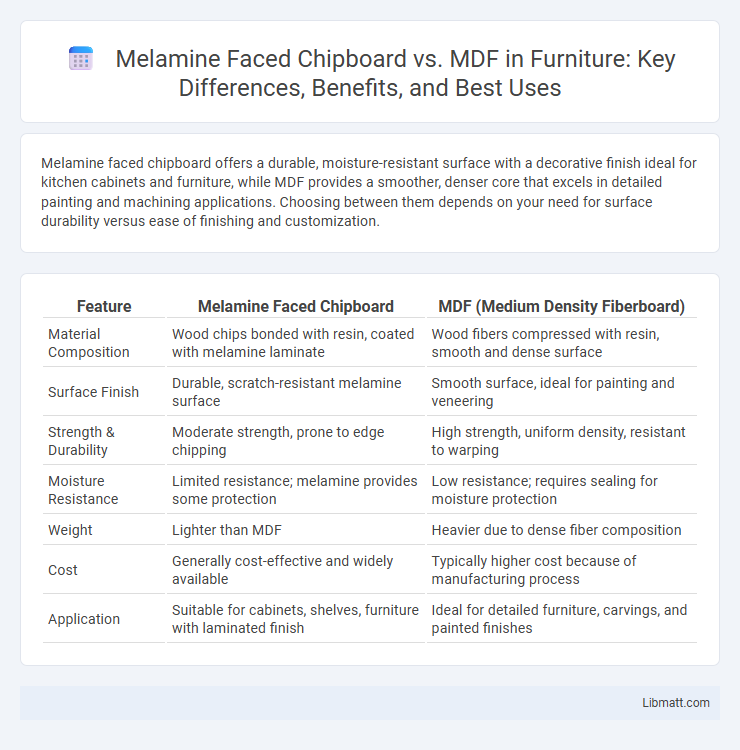

Melamine faced chipboard offers a durable, moisture-resistant surface with a decorative finish ideal for kitchen cabinets and furniture, while MDF provides a smoother, denser core that excels in detailed painting and machining applications. Choosing between them depends on your need for surface durability versus ease of finishing and customization.

Table of Comparison

| Feature | Melamine Faced Chipboard | MDF (Medium Density Fiberboard) |

|---|---|---|

| Material Composition | Wood chips bonded with resin, coated with melamine laminate | Wood fibers compressed with resin, smooth and dense surface |

| Surface Finish | Durable, scratch-resistant melamine surface | Smooth surface, ideal for painting and veneering |

| Strength & Durability | Moderate strength, prone to edge chipping | High strength, uniform density, resistant to warping |

| Moisture Resistance | Limited resistance; melamine provides some protection | Low resistance; requires sealing for moisture protection |

| Weight | Lighter than MDF | Heavier due to dense fiber composition |

| Cost | Generally cost-effective and widely available | Typically higher cost because of manufacturing process |

| Application | Suitable for cabinets, shelves, furniture with laminated finish | Ideal for detailed furniture, carvings, and painted finishes |

Introduction to Melamine Faced Chipboard and MDF

Melamine Faced Chipboard (MFC) is a type of engineered wood product made from chipboard coated with a decorative and durable melamine resin surface, providing resistance to scratches and moisture. Medium Density Fiberboard (MDF) is a dense, smooth panel produced by compressing wood fibers with resin, known for its uniform texture and suitability for detailed machining and painting. Both materials are commonly used in furniture and cabinetry, with MFC offering ready-to-use surfaces and MDF prized for its versatility and finish quality.

Composition and Manufacturing Process

Melamine faced chipboard (MFC) is made from wood chips and resin bonded under heat and pressure, then coated with a decorative melamine-impregnated paper layer for durability and moisture resistance. Medium Density Fiberboard (MDF) consists of fine wood fibers combined with wax and resin, compressed into dense, smooth panels through high-pressure pressing. Your choice depends on whether you prefer the rougher, economical composition of MFC or the uniform, fine texture and machinability of MDF.

Surface Finish and Aesthetic Options

Melamine faced chipboard offers a durable, pre-finished surface with a wide variety of colors and patterns, making it ideal for cabinetry and furniture that demand consistent texture and easy maintenance. MDF, on the other hand, provides a smooth and uniform surface ideal for painting or veneering, allowing for more customized aesthetic options and intricate designs. Your choice depends on whether you prioritize ready-to-use finishes or flexible, high-quality customization for your project's appearance.

Strength and Durability Comparison

Melamine-faced chipboard offers high resistance to scratches and moisture due to its laminated surface, making it suitable for kitchen and office furniture with moderate durability requirements. MDF, with its dense and uniform composition, provides superior strength and smoothness, ideal for detailed cabinetry and heavy-duty applications requiring greater load-bearing capacity. Your choice depends on whether you prioritize moisture resistance and cost-effectiveness (melamine chipboard) or structural integrity and finish quality (MDF).

Moisture and Heat Resistance

Melamine faced chipboard offers superior moisture resistance due to its sealed surface, making it ideal for damp environments compared to MDF, which is more prone to swelling when exposed to water. In terms of heat resistance, melamine faced chipboard withstands higher temperatures without warping, whereas MDF can deteriorate under prolonged heat exposure. These properties make melamine faced chipboard a preferred choice for kitchen and bathroom applications where moisture and heat are common factors.

Workability and Machining Differences

Melamine faced chipboard offers easier cutting and drilling due to its rigid structure and factory-applied melamine surface, which reduces the need for additional finishing but may cause chipping if not handled correctly. MDF, being denser and uniform, provides superior machining precision with smoother edges and less splintering, making it ideal for intricate routing and shaping. Workability of MDF is preferred for detailed craftsmanship, whereas melamine chipboard suits straightforward applications requiring durability and a finished look.

Cost Analysis and Affordability

Melamine faced chipboard typically offers a lower cost compared to MDF, making it a budget-friendly option for furniture and cabinetry projects where surface durability is essential. MDF, while slightly more expensive, delivers a smoother finish and greater density, which can justify higher upfront costs with enhanced longevity and paintability. Affordability considerations depend on project requirements, with melamine chipboard preferred for cost-sensitive applications and MDF favored when superior finish quality and workability are priorities.

Environmental Impact and Sustainability

Melamine faced chipboard is often favored for its use of wood residues and lower energy consumption during production, making it a more sustainable option compared to MDF, which typically requires more intensive processing and resin use. However, both materials involve formaldehyde-based adhesives that can affect indoor air quality and environmental health if not properly managed. Advances in low-emission binders and recycling practices are critical to reducing the environmental impact and enhancing the sustainability of both melamine faced chipboard and MDF in construction and furniture manufacturing.

Common Applications in Furniture and Interiors

Melamine faced chipboard is widely used in kitchen cabinets, wardrobes, and office furniture due to its durability and moisture resistance. MDF is preferred for decorative moldings, furniture panels, and interior doors because of its smooth surface and ease of machining. Both materials offer cost-effective solutions for furniture and interior design, with melamine faced chipboard excelling in practical applications and MDF favored for detailed finishes.

Choosing Between Melamine Faced Chipboard and MDF

Melamine faced chipboard offers a durable, moisture-resistant surface ideal for kitchen cabinets and wardrobes, while MDF provides a smoother, denser core suited for intricate woodworking and painted finishes. Melamine chipboard is cost-effective with a wide variety of decorative finishes, making it favorable for budget-conscious projects requiring easy maintenance. MDF's uniform texture allows superior adhesion of paint and veneers, preferred for custom furniture and designs demanding high precision.

melamine faced chipboard vs MDF Infographic

libmatt.com

libmatt.com