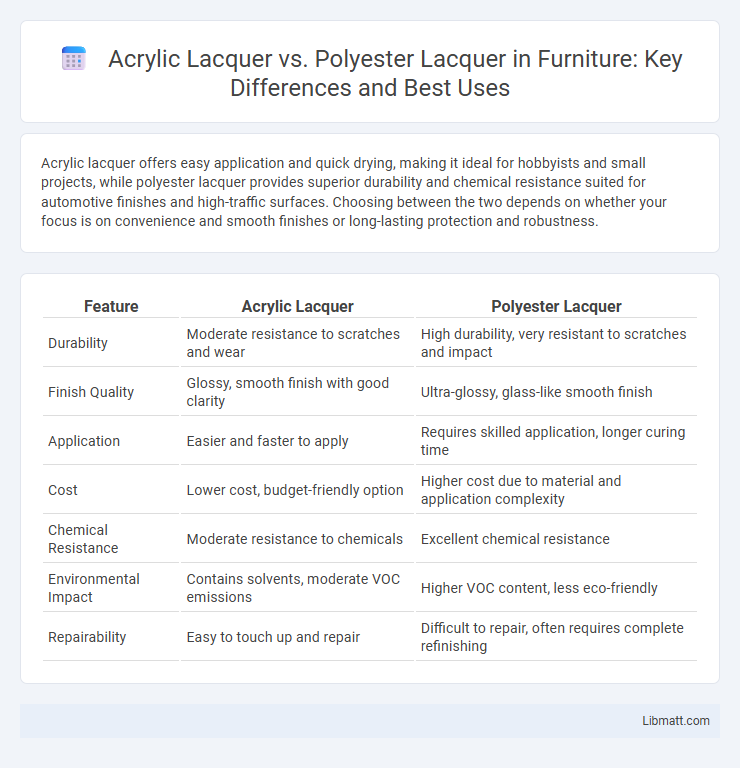

Acrylic lacquer offers easy application and quick drying, making it ideal for hobbyists and small projects, while polyester lacquer provides superior durability and chemical resistance suited for automotive finishes and high-traffic surfaces. Choosing between the two depends on whether your focus is on convenience and smooth finishes or long-lasting protection and robustness.

Table of Comparison

| Feature | Acrylic Lacquer | Polyester Lacquer |

|---|---|---|

| Durability | Moderate resistance to scratches and wear | High durability, very resistant to scratches and impact |

| Finish Quality | Glossy, smooth finish with good clarity | Ultra-glossy, glass-like smooth finish |

| Application | Easier and faster to apply | Requires skilled application, longer curing time |

| Cost | Lower cost, budget-friendly option | Higher cost due to material and application complexity |

| Chemical Resistance | Moderate resistance to chemicals | Excellent chemical resistance |

| Environmental Impact | Contains solvents, moderate VOC emissions | Higher VOC content, less eco-friendly |

| Repairability | Easy to touch up and repair | Difficult to repair, often requires complete refinishing |

Introduction to Acrylic and Polyester Lacquer

Acrylic lacquer is a fast-drying, durable finish made from acrylic resins, offering excellent clarity and UV resistance, ideal for protecting wood and metal surfaces with a smooth, glossy appearance. Polyester lacquer, crafted from polyester resins, provides superior hardness and chemical resistance, making it a preferred choice for automotive and high-end woodworking applications where durability and a deep, glass-like finish are essential. Understanding the differences in drying time, flexibility, and final appearance can help you select the best lacquer for your specific project needs.

Chemical Composition Differences

Acrylic lacquer contains nitrocellulose combined with acrylic resins, resulting in a faster-drying, flexible finish that enhances colors with a high-gloss sheen. Polyester lacquer, made from a thermosetting polyester resin, offers superior durability, chemical resistance, and a thicker, more robust coating ideal for heavy-use surfaces. Understanding these chemical composition differences helps you choose the right lacquer based on your project's durability and aesthetic requirements.

Application Techniques Compared

Acrylic lacquer requires multiple thin coats applied with a high-volume, low-pressure (HVLP) spray gun to achieve a smooth, even finish, drying quickly between layers for easier buffing and polishing. Polyester lacquer demands a meticulous application process, often involving precise sanding between coats to ensure an ultra-durable, high-gloss surface, but it is more sensitive to over-application and environmental conditions. Your choice will affect the technique complexity and finish quality, with acrylic lacquer suited for ease of use and polyester lacquer excelling in durability and depth.

Drying and Curing Times

Acrylic lacquer typically dries faster, often within 15 to 30 minutes, providing a quick-touch surface ready for light handling. Polyester lacquer requires longer curing times, sometimes up to several days, to achieve full chemical resistance and durability. Your choice depends on project deadlines and the desired finish longevity, with acrylic offering speed and polyester ensuring a tougher, more resilient coat.

Durability and Scratch Resistance

Polyester lacquer offers superior durability and scratch resistance compared to acrylic lacquer, making it ideal for high-traffic surfaces in automotive and furniture applications. Acrylic lacquer provides excellent clarity and ease of application but tends to be more prone to scratches and wear over time. Professionals often choose polyester lacquer for long-lasting protection in environments requiring tough, resilient finishes.

Aesthetic Qualities and Finish Options

Acrylic lacquer offers a high-gloss, smooth finish with excellent color clarity and UV resistance, making it ideal for vibrant, detailed projects that demand a polished aesthetic. Polyester lacquer provides a thicker, more durable coating with superior chemical and scratch resistance, often resulting in a deeper, glass-like finish preferred for automotive and high-end woodworking applications. Your choice between acrylic and polyester lacquer will depend on the desired balance between visual appeal and long-lasting protection.

Suitability for Different Surfaces

Acrylic lacquer offers excellent adhesion and flexibility, making it ideal for wood, metal, and plastic surfaces, especially in automotive and furniture applications where a smooth, glossy finish is desired. Polyester lacquer provides superior hardness and chemical resistance, making it suitable for high-wear surfaces like piano cabinets and industrial equipment that require durable, long-lasting protection. Choosing between acrylic and polyester lacquers depends on the specific surface type and the level of durability and finish quality needed.

Environmental and Safety Considerations

Acrylic lacquer emits lower levels of volatile organic compounds (VOCs) compared to polyester lacquer, making it a more environmentally friendly choice for finishing projects. Polyester lacquer contains higher VOC concentrations and hazardous chemicals that require stringent ventilation and protective equipment during application to ensure worker safety. Proper disposal and handling protocols are essential for both lacquers to minimize environmental impact and health risks.

Cost and Availability

Acrylic lacquer generally costs less and is more readily available at local hardware stores, making it a popular choice for DIY projects and small-scale applications. Polyester lacquer, while more expensive, offers superior durability and is often found through specialty suppliers or professional-grade retailers. Your choice may depend on budget constraints and access to these materials in your area.

Choosing the Right Lacquer for Your Project

Acrylic lacquer offers excellent clarity and ease of application, making it ideal for projects requiring a smooth, glossy finish with quick drying times. Polyester lacquer provides superior durability and chemical resistance, perfect for surfaces exposed to heavy wear or outdoor conditions. Choosing the right lacquer depends on your project's requirements for finish quality, durability, and environmental exposure.

acrylic lacquer vs polyester lacquer Infographic

libmatt.com

libmatt.com