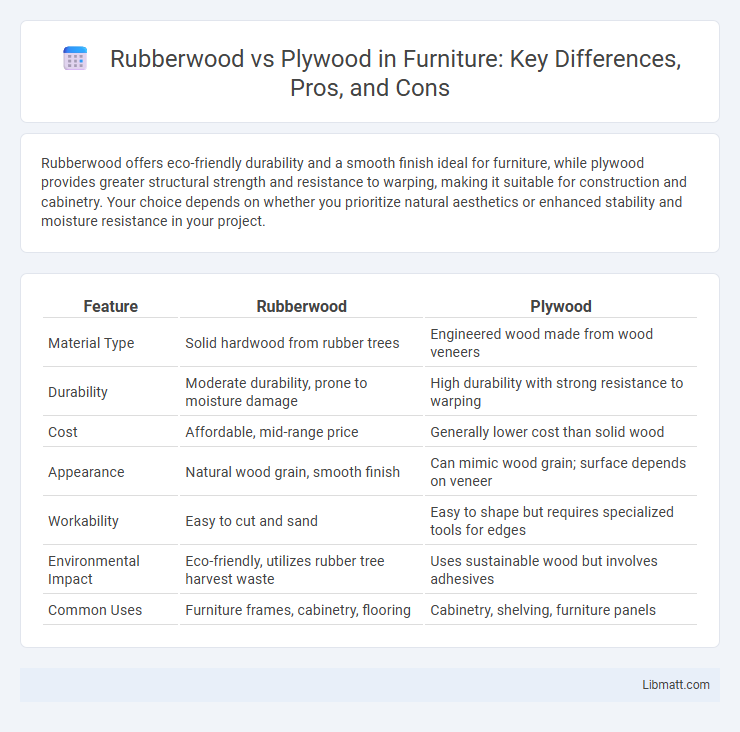

Rubberwood offers eco-friendly durability and a smooth finish ideal for furniture, while plywood provides greater structural strength and resistance to warping, making it suitable for construction and cabinetry. Your choice depends on whether you prioritize natural aesthetics or enhanced stability and moisture resistance in your project.

Table of Comparison

| Feature | Rubberwood | Plywood |

|---|---|---|

| Material Type | Solid hardwood from rubber trees | Engineered wood made from wood veneers |

| Durability | Moderate durability, prone to moisture damage | High durability with strong resistance to warping |

| Cost | Affordable, mid-range price | Generally lower cost than solid wood |

| Appearance | Natural wood grain, smooth finish | Can mimic wood grain; surface depends on veneer |

| Workability | Easy to cut and sand | Easy to shape but requires specialized tools for edges |

| Environmental Impact | Eco-friendly, utilizes rubber tree harvest waste | Uses sustainable wood but involves adhesives |

| Common Uses | Furniture frames, cabinetry, flooring | Cabinetry, shelving, furniture panels |

Introduction to Rubberwood and Plywood

Rubberwood, derived from the Para rubber tree (Hevea brasiliensis), is a sustainable hardwood known for its durability and fine texture, commonly used in furniture manufacturing. Plywood is an engineered wood product made from thin layers of wood veneer glued together, offering high strength and resistance to warping. Your choice between rubberwood and plywood depends on factors like environmental impact, appearance, and specific application requirements.

Origins and Source Materials

Rubberwood originates from the Para rubber tree (Hevea brasiliensis), primarily sourced from Southeast Asia, especially Malaysia and Thailand, where used rubber trees are repurposed after latex extraction. Plywood is manufactured by layering thin veneers of various softwood or hardwood species, such as pine, birch, or oak, bonded together with adhesive under heat and pressure. While rubberwood is a solid timber harvested from plantation trees, plywood is an engineered wood product designed to maximize strength and stability from multiple wood layers.

Manufacturing Processes

Rubberwood is manufactured by kiln-drying the timber derived from rubber trees, ensuring moisture content is minimized for durability and stability, followed by processing into solid lumber or engineered wood products. Plywood is produced by gluing together multiple thin layers, or veneers, of wood with the grain of adjacent layers oriented perpendicular, creating a strong, flexible panel. The manufacturing process of rubberwood emphasizes sustainability through utilizing plantation trees, while plywood manufacturing focuses on structural strength and uniformity.

Physical Properties and Appearance

Rubberwood features a light, creamy color with a straight grain, known for its moderate hardness and durability, making it suitable for furniture that requires a smooth finish and natural look. Plywood is composed of thin layers of wood veneer glued together, offering superior strength and resistance to warping due to its cross-grain construction, but it often has a less uniform appearance with visible layers on the edges. Your choice between rubberwood and plywood depends on whether you prioritize aesthetic appeal or structural integrity for your project.

Strength and Durability Comparison

Rubberwood offers moderate strength and durability, making it suitable for lightweight furniture and indoor use, while plywood boasts superior strength due to its layered construction, providing enhanced resistance to warping and splitting. Plywood's cross-grain layers give it higher load-bearing capacity and better moisture resistance compared to rubberwood, which can be prone to damage in humid environments. When choosing materials for your project, plywood is ideal for demanding applications requiring long-term durability, whereas rubberwood suits budget-friendly, aesthetically pleasing indoor furniture.

Environmental Impact and Sustainability

Rubberwood is a sustainable choice as it utilizes the byproduct of the latex industry, reducing deforestation and promoting responsible forestry practices. Plywood production often involves adhesives containing formaldehyde, which can release harmful VOCs, impacting indoor air quality and the environment. Choosing rubberwood supports eco-friendly craftsmanship while minimizing your carbon footprint.

Cost Differences

Rubberwood typically costs more than plywood due to its sustainable sourcing and durability, making it a preferred choice in quality furniture manufacturing. Plywood, being manufactured from thin layers of wood veneer, offers a more affordable option ideal for budget-sensitive projects and structural applications. Cost variability depends on factors like thickness, grade, and intended use, with rubberwood often commanding higher prices in retail markets.

Common Applications and Uses

Rubberwood is commonly used in furniture production, cabinetry, and interior fixtures due to its durability and attractive grain pattern, making it ideal for eco-friendly wood products. Plywood's layered construction provides superior strength and stability, which suits applications such as subflooring, wall sheathing, roofing, and industrial packaging. Both materials find frequent use in cabinetry and furniture, but plywood is preferred for structural projects requiring moisture resistance and load-bearing capacity.

Maintenance and Care

Rubberwood requires minimal maintenance, needing only regular dusting and occasional wiping with a damp cloth to preserve its natural finish and prevent warping. Plywood demands more careful handling to avoid moisture damage, often requiring sealing or varnishing to maintain durability and appearance over time. Your choice between rubberwood and plywood should consider how much upkeep you are willing to invest to keep furniture looking its best.

Which Is Better: Rubberwood or Plywood?

Rubberwood offers a sustainable, eco-friendly choice with durability and natural resistance to decay, making it ideal for furniture and indoor applications. Plywood provides superior strength and stability due to its layered construction, excelling in structural uses and areas exposed to moisture. Choosing between rubberwood and plywood depends on project requirements, with plywood favored for load-bearing tasks and rubberwood preferred for cost-effective, aesthetically pleasing indoor furniture.

Rubberwood vs plywood Infographic

libmatt.com

libmatt.com