Anti-corrosive glass offers enhanced durability and resistance to weathering, chemicals, and moisture compared to regular glass, making it ideal for harsh environments. Choosing this specialized glass protects your investment by preventing corrosion-related damage and extending the lifespan of windows and surfaces.

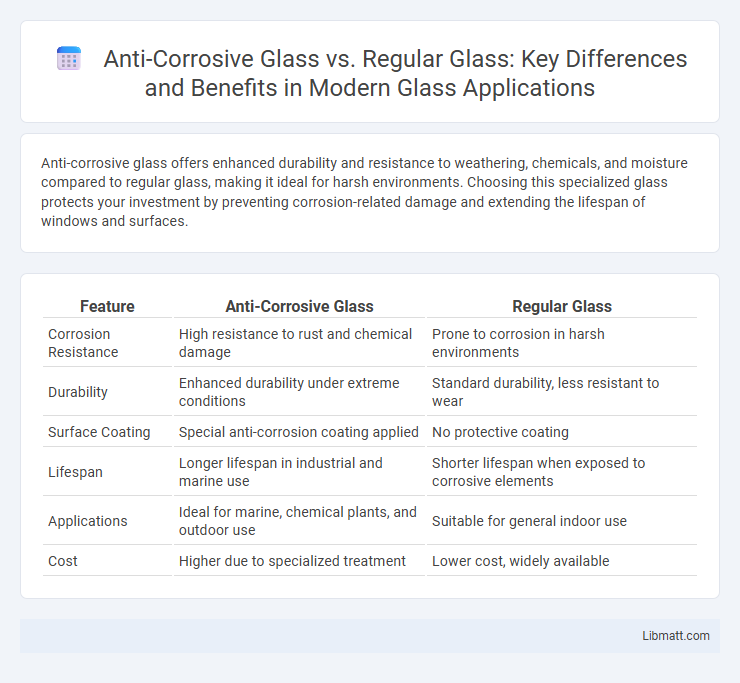

Table of Comparison

| Feature | Anti-Corrosive Glass | Regular Glass |

|---|---|---|

| Corrosion Resistance | High resistance to rust and chemical damage | Prone to corrosion in harsh environments |

| Durability | Enhanced durability under extreme conditions | Standard durability, less resistant to wear |

| Surface Coating | Special anti-corrosion coating applied | No protective coating |

| Lifespan | Longer lifespan in industrial and marine use | Shorter lifespan when exposed to corrosive elements |

| Applications | Ideal for marine, chemical plants, and outdoor use | Suitable for general indoor use |

| Cost | Higher due to specialized treatment | Lower cost, widely available |

Introduction to Glass Types

Anti-corrosive glass features special coatings and treatments that enhance resistance to chemical damage and environmental corrosion, unlike regular glass which lacks these protective properties. This makes anti-corrosive glass ideal for industrial, marine, and outdoor applications where exposure to harsh elements can degrade standard glass over time. Understanding these differences helps you select the appropriate glass type for durability and long-term performance in corrosive environments.

What is Anti-Corrosive Glass?

Anti-corrosive glass is specially engineered with coatings or chemical treatments that resist oxidation and degradation caused by environmental factors such as moisture, salt, and pollutants. Unlike regular glass, which can deteriorate or develop surface flaws over time when exposed to corrosive conditions, anti-corrosive glass maintains clarity, strength, and durability in harsh environments. This type of glass is commonly used in marine, industrial, and medical applications where prolonged exposure to corrosive elements is a concern.

Composition Differences: Anti-Corrosive vs Regular Glass

Anti-corrosive glass incorporates a specialized alkaline-resistant coating or is formulated with higher silica content to prevent degradation caused by chemicals and moisture, unlike regular glass which typically lacks such protective layers and is prone to corrosion in harsh environments. The enhanced composition of anti-corrosive glass often includes additives like fluorine or titanium dioxide to bolster its chemical stability and longevity. Regular glass mainly consists of silica, soda, and lime, making it susceptible to surface pitting and clouding when exposed to corrosive agents.

How Corrosion Affects Glass Surfaces

Corrosion affects glass surfaces by causing etching, discoloration, and a loss of transparency, which can compromise both aesthetics and structural integrity. Anti-corrosive glass is treated with special coatings or additives that create a protective barrier, preventing chemical reactions with environmental elements like moisture, acids, and salts. Your choice of anti-corrosive glass ensures longer-lasting clarity and durability compared to regular glass exposed to harsh conditions.

Performance and Durability Comparison

Anti-corrosive glass offers superior resistance to chemical degradation, moisture, and environmental elements compared to regular glass, significantly enhancing its longevity in harsh conditions. Its specialized coatings prevent oxidation and surface pitting, maintaining optical clarity and structural integrity over time. Regular glass, lacking these protective treatments, is more susceptible to corrosion, scratches, and clouding, resulting in reduced performance and durability.

Applications of Anti-Corrosive Glass

Anti-corrosive glass is extensively used in marine environments, chemical processing plants, and outdoor architectural structures due to its enhanced resistance to moisture, salt, and harsh chemicals. Unlike regular glass, anti-corrosive glass maintains clarity and structural integrity in aggressive environments, reducing maintenance and replacement costs. Its specialized coatings also make it ideal for use in solar panels, automotive windshields, and electronic displays to prevent corrosion and extend product lifespan.

Cost Analysis: Anti-Corrosive vs Regular Glass

Anti-corrosive glass typically incurs a higher initial cost compared to regular glass due to specialized coatings and manufacturing processes that enhance durability against chemical and environmental damage. Despite the upfront expense, anti-corrosive glass offers long-term value by reducing maintenance costs and extending lifespan in harsh conditions, particularly in industrial or marine applications. Regular glass, while cheaper initially, may require frequent replacements or treatments, leading to increased total ownership costs over time.

Maintenance and Longevity Factors

Anti-corrosive glass requires significantly lower maintenance than regular glass due to its protective coatings that resist oxidation and environmental wear. This specialized glass extends longevity by preventing common issues such as rust stains, surface degradation, and structural weakening caused by prolonged exposure to moisture and chemicals. Regular glass, lacking these treatments, demands frequent cleaning and replacement to maintain clarity and structural integrity in harsh conditions.

Environmental Benefits and Sustainability

Anti-corrosive glass offers superior environmental benefits compared to regular glass by significantly extending the lifespan of structures, reducing the frequency of replacements and minimizing resource consumption. Its enhanced durability decreases the need for energy-intensive manufacturing and transportation processes, contributing to lower carbon emissions and waste generation. Choosing anti-corrosive glass supports your sustainability goals by promoting long-term material efficiency and reducing the ecological footprint of construction projects.

Choosing the Right Glass for Your Needs

Anti-corrosive glass offers enhanced durability and resistance to chemical damage compared to regular glass, making it ideal for environments exposed to moisture, salt, or harsh chemicals. Regular glass may suffice for indoor or low-exposure settings, but it is prone to corrosion and etching over time, affecting clarity and strength. Selecting anti-corrosive glass ensures long-term performance and visual integrity in industrial, marine, or high-humidity applications, while regular glass remains a cost-effective choice for general use.

anti-corrosive glass vs regular glass Infographic

libmatt.com

libmatt.com