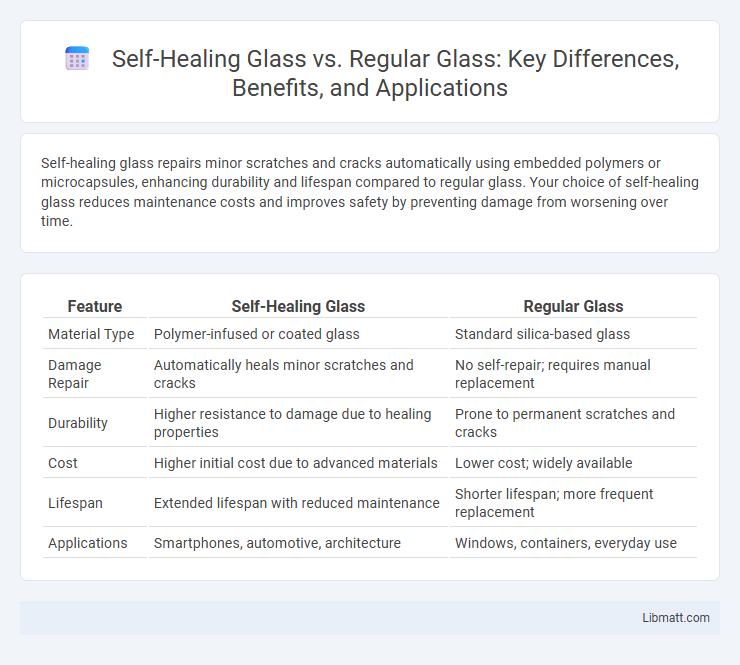

Self-healing glass repairs minor scratches and cracks automatically using embedded polymers or microcapsules, enhancing durability and lifespan compared to regular glass. Your choice of self-healing glass reduces maintenance costs and improves safety by preventing damage from worsening over time.

Table of Comparison

| Feature | Self-Healing Glass | Regular Glass |

|---|---|---|

| Material Type | Polymer-infused or coated glass | Standard silica-based glass |

| Damage Repair | Automatically heals minor scratches and cracks | No self-repair; requires manual replacement |

| Durability | Higher resistance to damage due to healing properties | Prone to permanent scratches and cracks |

| Cost | Higher initial cost due to advanced materials | Lower cost; widely available |

| Lifespan | Extended lifespan with reduced maintenance | Shorter lifespan; more frequent replacement |

| Applications | Smartphones, automotive, architecture | Windows, containers, everyday use |

Introduction to Self-Healing Glass and Regular Glass

Self-healing glass incorporates advanced polymer technology that enables it to repair minor cracks and scratches autonomously, enhancing durability and lifespan compared to regular glass. Regular glass, typically composed of silica and formed through a cooling process, remains rigid and vulnerable to permanent damage when impacted or scratched. Understanding the unique properties of self-healing glass can help you invest in materials that offer long-term resilience and reduced maintenance costs.

How Self-Healing Glass Works

Self-healing glass contains microcapsules filled with healing agents embedded within its structure, which activate upon damage to repair cracks and scratches autonomously. When the glass is damaged, these capsules rupture, releasing the healing agents that chemically bond with the surrounding material, effectively restoring the surface without manual intervention. This innovative technology enhances durability and longevity compared to regular glass, which requires external repair or replacement after damage.

Composition and Manufacturing Differences

Self-healing glass incorporates microcapsules or embedded polymers that react to cracks by filling and bonding the damaged area, unlike regular glass made solely from silica and other inorganic materials. Manufacturing self-healing glass involves advanced techniques to integrate these self-repair components, requiring precise polymer embedding or coating processes, whereas regular glass follows traditional melting and cooling methods. Your choice of self-healing glass ensures enhanced durability through innovative material composition and specialized production methods.

Durability and Scratch Resistance Comparison

Self-healing glass demonstrates superior durability compared to regular glass by effectively repairing minor scratches and surface damage autonomously, extending its lifespan. Regular glass lacks this ability, often showing permanent scratches that weaken structural integrity over time. The self-healing mechanism significantly enhances scratch resistance, maintaining clarity and strength under repeated stress that would degrade conventional glass.

Self-Healing Glass vs Regular Glass in Everyday Applications

Self-healing glass offers enhanced durability and longevity by autonomously repairing minor scratches and cracks, significantly reducing maintenance costs compared to regular glass. In everyday applications such as smartphone screens, automotive windows, and building facades, this innovation ensures clearer visibility and improved safety over time. You benefit from reduced replacements and extended product life, making self-healing glass a superior choice in high-use environments.

Cost Analysis: Is Self-Healing Glass Worth It?

Self-healing glass typically incurs higher initial costs compared to regular glass due to advanced materials and manufacturing processes that enable automatic repair of minor scratches and cracks. Although the upfront investment is greater, the long-term savings on maintenance, replacements, and enhanced durability often justify the expense, especially in high-use or safety-critical applications. Cost-benefit analysis reveals that self-healing glass reduces total lifecycle costs by minimizing damage-related downtime and preserving structural integrity over time.

Environmental Impact of Both Glass Types

Self-healing glass significantly reduces environmental impact by extending the lifespan of windows and screens, minimizing waste and the need for frequent replacements. Regular glass, prone to cracking and breaking, often ends up in landfills, increasing material waste and energy consumption for production. You can contribute to sustainability by choosing self-healing glass, which promotes resource efficiency and lowers overall carbon footprint.

Maintenance and Longevity

Self-healing glass significantly reduces maintenance efforts by automatically repairing minor scratches and cracks, extending its functional lifespan compared to regular glass. This advanced material boasts increased longevity as it resists damage accumulation that typically leads to costly replacements. Regular glass, lacking self-repair capabilities, often requires frequent upkeep or replacement to maintain clarity and structural integrity.

Safety Features and Limitations

Self-healing glass enhances safety by quickly repairing minor cracks and scratches, reducing the risk of shattering and maintaining structural integrity. In contrast, regular glass lacks this capability, making it more prone to sudden breakage under stress or impact. Limitations of self-healing glass include slower healing times for extensive damage and potential reduction in clarity after repeated repairs, whereas regular glass offers consistent optical properties but no damage recovery.

Future Trends in Glass Technology

Self-healing glass represents a breakthrough in glass technology by incorporating microcapsules or polymeric materials that automatically repair surface damage, significantly enhancing durability compared to regular glass. Future trends in glass technology emphasize the integration of smart materials, such as self-healing polymers and nanomaterials, to improve longevity, safety, and energy efficiency in applications ranging from consumer electronics to automotive and architectural glass. Advances in nanotechnology and materials science are driving the development of adaptive glass surfaces with self-healing capabilities, positioning this innovation as a key component in next-generation sustainable and resilient building designs.

self-healing glass vs regular glass Infographic

libmatt.com

libmatt.com