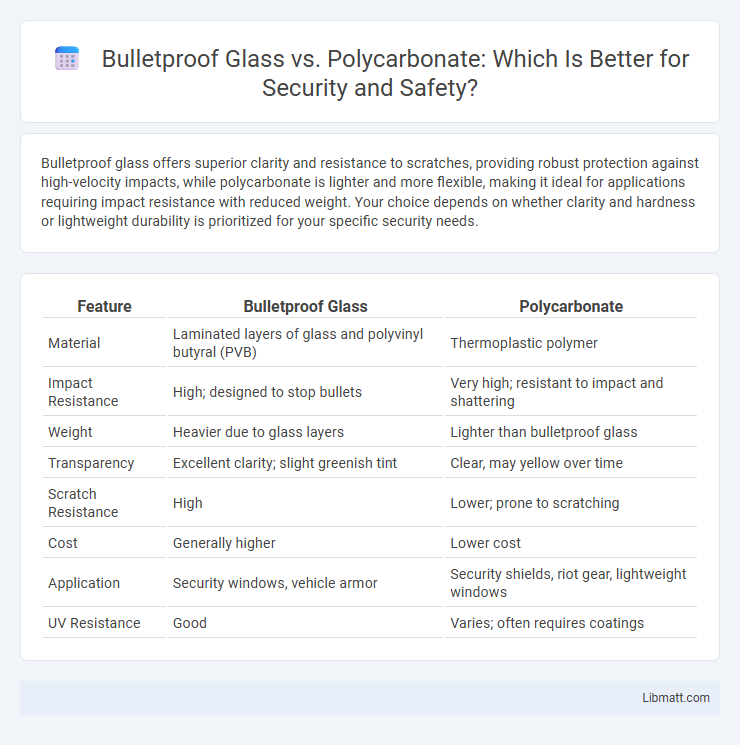

Bulletproof glass offers superior clarity and resistance to scratches, providing robust protection against high-velocity impacts, while polycarbonate is lighter and more flexible, making it ideal for applications requiring impact resistance with reduced weight. Your choice depends on whether clarity and hardness or lightweight durability is prioritized for your specific security needs.

Table of Comparison

| Feature | Bulletproof Glass | Polycarbonate |

|---|---|---|

| Material | Laminated layers of glass and polyvinyl butyral (PVB) | Thermoplastic polymer |

| Impact Resistance | High; designed to stop bullets | Very high; resistant to impact and shattering |

| Weight | Heavier due to glass layers | Lighter than bulletproof glass |

| Transparency | Excellent clarity; slight greenish tint | Clear, may yellow over time |

| Scratch Resistance | High | Lower; prone to scratching |

| Cost | Generally higher | Lower cost |

| Application | Security windows, vehicle armor | Security shields, riot gear, lightweight windows |

| UV Resistance | Good | Varies; often requires coatings |

Understanding Bulletproof Glass

Bulletproof glass, also known as ballistic glass, consists of multiple layers of laminated glass and polycarbonate designed to absorb and disperse the impact from bullets, providing high-level protection against firearms. Unlike polycarbonate alone, which is a single resin sheet offering flexibility and impact resistance, bulletproof glass combines the hardness of glass with the toughness of polycarbonate to prevent penetration and maintain clarity. Understanding bulletproof glass helps you choose the right material for secure environments where both visibility and safety are critical.

What is Polycarbonate?

Polycarbonate is a durable, lightweight thermoplastic known for its exceptional impact resistance and clarity, making it ideal for protective applications. Unlike traditional glass, polycarbonate can absorb significant force without shattering, enhancing safety in bulletproof and security windows. Its high strength-to-weight ratio and ease of fabrication offer a versatile alternative to bulletproof glass in various defense and commercial settings.

Key Differences Between Bulletproof Glass and Polycarbonate

Bulletproof glass, typically composed of laminated layers of glass and polycarbonate, offers superior transparency and scratch resistance compared to pure polycarbonate sheets, which are lighter and more impact-resistant but prone to scratching. Polycarbonate provides enhanced flexibility and shatter resistance, making it ideal for applications requiring lightweight protection, whereas bulletproof glass excels in rigid ballistic defense with higher clarity. The key difference lies in bulletproof glass's multi-layered structure optimizing ballistic resistance and optical clarity, while polycarbonate focuses on weight reduction and impact absorption.

Security Levels: Bullet Resistance Comparison

Bulletproof glass offers higher levels of bullet resistance due to its multi-layered construction combining glass and polyvinyl butyral (PVB) or other interlayers, effectively stopping various calibers of bullets. Polycarbonate provides excellent impact resistance with lighter weight and flexibility, but generally withstands lower ballistic threats compared to bulletproof glass. Your security needs determine which material suits best, as bulletproof glass is ideal for high-level protection, while polycarbonate suits moderate security environments.

Weight and Thickness Considerations

Bulletproof glass typically weighs more and is thicker than polycarbonate for the same level of ballistic protection, impacting installation and structural support requirements. Polycarbonate offers significant weight savings, often up to 50-70% lighter, while maintaining comparable impact resistance with thinner profiles. These differences make polycarbonate advantageous in applications where reducing weight and thickness is critical without compromising safety.

Installation and Maintenance Requirements

Bulletproof glass requires professional installation due to its heavy weight and precise sealing needs, ensuring optimal security and durability. Polycarbonate is lighter and easier to install, often allowing for simpler, less costly fitting processes and more flexible mounting options. Your maintenance regimen for bulletproof glass involves regular inspection for cracks and seal integrity, whereas polycarbonate demands frequent cleaning to prevent scratching and UV degradation.

Cost Analysis: Bulletproof Glass vs Polycarbonate

Bulletproof glass typically costs between $25 to $100 per square foot, making it significantly more expensive than polycarbonate, which ranges from $15 to $60 per square foot. While bulletproof glass offers superior clarity and high resistance to impact, polycarbonate provides comparable protection at a lower price and with greater flexibility and lighter weight. Long-term maintenance costs also favor polycarbonate due to its higher shatter resistance and easier replacement options.

Durability and Longevity

Bulletproof glass offers exceptional durability due to its multi-layered construction of glass and polycarbonate, providing high resistance to impact and scratching while maintaining clarity over time. Polycarbonate, known for its superior impact resistance and lightweight properties, is more prone to surface scratches and may require additional coatings for enhanced longevity. The longevity of bulletproof glass typically surpasses that of polycarbonate alone, making it a preferred choice for applications demanding long-term durability and sustained protective performance.

Common Applications in Security

Bulletproof glass is commonly used in high-security settings such as bank teller windows, armored vehicles, and government buildings due to its ability to resist high-velocity projectiles and blunt force impacts. Polycarbonate is frequently employed in riot shields, safety helmets, and protective barriers, offering lightweight, shatter-resistant protection ideal for rapid deployment and impact absorption. Your choice between bulletproof glass and polycarbonate should depend on the specific security requirements, balancing impact resistance, weight, and visibility needs.

Choosing the Right Material for Your Needs

Bulletproof glass offers superior clarity and long-lasting protection against high-caliber firearms, making it ideal for secure installations in banks and government buildings. Polycarbonate is lighter, more impact-resistant, and easier to install, often preferred for automotive and portable security applications. Evaluating factors such as thickness, weight, threat level, and installation environment helps determine the most effective material for your specific security requirements.

bulletproof glass vs polycarbonate Infographic

libmatt.com

libmatt.com