Float glass offers a smoother, more uniform surface and is produced by floating molten glass on a bed of molten metal, making it ideal for window panes and mirrors. Plate glass, thicker and heavier, undergoes additional polishing and grinding processes, providing greater strength and clarity for architectural applications and high-quality glazing.

Table of Comparison

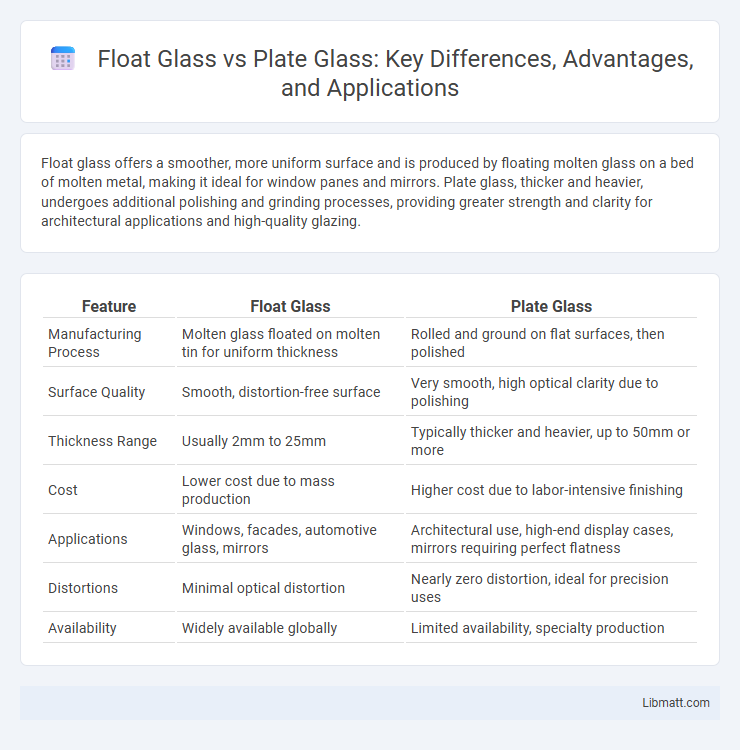

| Feature | Float Glass | Plate Glass |

|---|---|---|

| Manufacturing Process | Molten glass floated on molten tin for uniform thickness | Rolled and ground on flat surfaces, then polished |

| Surface Quality | Smooth, distortion-free surface | Very smooth, high optical clarity due to polishing |

| Thickness Range | Usually 2mm to 25mm | Typically thicker and heavier, up to 50mm or more |

| Cost | Lower cost due to mass production | Higher cost due to labor-intensive finishing |

| Applications | Windows, facades, automotive glass, mirrors | Architectural use, high-end display cases, mirrors requiring perfect flatness |

| Distortions | Minimal optical distortion | Nearly zero distortion, ideal for precision uses |

| Availability | Widely available globally | Limited availability, specialty production |

Introduction to Float Glass and Plate Glass

Float glass, produced by floating molten glass on a bed of molten tin, offers a uniform thickness and smooth surface ideal for architectural and automotive applications. Plate glass, manufactured by casting molten glass onto a flat surface followed by mechanical grinding and polishing, provides a thicker, more optically perfect finish used in high-end mirrors and specialty glazing. Both types serve distinct purposes based on their production methods, surface quality, and cost-efficiency.

Historical Development of Glass Manufacturing

Float glass revolutionized glass manufacturing after its invention by Sir Alastair Pilkington in 1959, enabling the production of smooth, uniform sheets by floating molten glass on a bed of molten tin. Plate glass, developed much earlier in the 17th century, involved casting molten glass onto a flat surface and then grinding and polishing it to achieve clarity and smoothness. The float glass process significantly reduced production costs and improved optical quality compared to the labor-intensive plate glass method.

Manufacturing Process: Float Glass vs Plate Glass

Float glass is produced by floating molten glass on a bed of molten tin, resulting in a smooth, uniform thickness and high optical clarity, while plate glass is manufactured by casting molten glass onto a flat surface and then mechanically polishing and grinding it to achieve a smooth finish. The float glass process allows for continuous production with fewer imperfections and lower costs compared to the labor-intensive and time-consuming plate glass method. Your choice between float glass and plate glass may depend on the required surface quality, thickness tolerance, and budget constraints.

Physical Properties Comparison

Float glass exhibits a uniform thickness and smooth surface achieved through a continuous molten glass floating process on molten tin, resulting in minimal internal stresses and high optical clarity. Plate glass, produced by casting molten glass onto a metal table and then grinding and polishing, features a thicker, heavier composition with lower optical quality due to surface imperfections and micro-scratches. The thermal and mechanical strength of float glass surpasses that of plate glass, making float glass more suitable for architectural and automotive applications requiring consistent performance and higher durability.

Optical Clarity and Distortion

Float glass offers superior optical clarity and minimal distortion due to its manufacturing process, where molten glass is floated on a bed of molten metal, resulting in a smooth and uniform surface. Plate glass, produced by rolling and polishing, often exhibits slight imperfections and distortions that can affect visual quality. For applications requiring high clarity and consistent transparency, your best choice is float glass over plate glass.

Strength and Durability Differences

Float glass offers greater uniformity and strength due to its even cooling process on a molten bed, resulting in fewer internal stresses compared to plate glass. Plate glass, being older in manufacturing technique, often contains surface imperfections that reduce its durability and resistance to impact. Your choice between these glass types should consider float glass for applications requiring enhanced strength and long-term durability.

Surface Quality and Thickness Consistency

Float glass offers superior surface quality with a smooth, uniform finish due to its production process on molten metal, minimizing distortions and imperfections. Plate glass, while thicker and heavier, often exhibits less consistency in thickness and can have minor surface irregularities from grinding and polishing. Your choice depends on the need for precise thickness uniformity and impeccable surface clarity, with float glass excelling in both aspects.

Applications in Architecture and Industry

Float glass, characterized by its uniform thickness and smooth surfaces, is widely used in architectural applications such as windows, facades, and curtain walls due to its clarity and cost-effectiveness. Plate glass, known for its superior optical quality and thickness variations, is preferred in industries requiring precision, such as automotive manufacturing, mirrors, and specialized glazing. Both types serve essential roles, with float glass dominating large-scale construction and plate glass fulfilling niche industrial needs demanding high durability and clarity.

Cost and Availability Comparison

Float glass is generally more cost-effective and widely available due to its efficient manufacturing process that produces large, uniform sheets at scale. Plate glass, being thicker and requiring more labor-intensive polishing, is typically more expensive and harder to source in large quantities. When considering your project budget and timeline, float glass offers a more affordable and accessible option for most standard glazing needs.

Which is Better: Choosing Between Float Glass and Plate Glass

Float glass offers superior optical clarity and uniform thickness due to its manufacturing process, making it ideal for windows, mirrors, and automotive uses. Plate glass, known for its polished surfaces and greater thickness, is preferred in architectural applications requiring high strength and aesthetic appeal. Selecting between float glass and plate glass depends on specific project needs such as clarity, thickness, durability, and cost-effectiveness.

Float glass vs plate glass Infographic

libmatt.com

libmatt.com