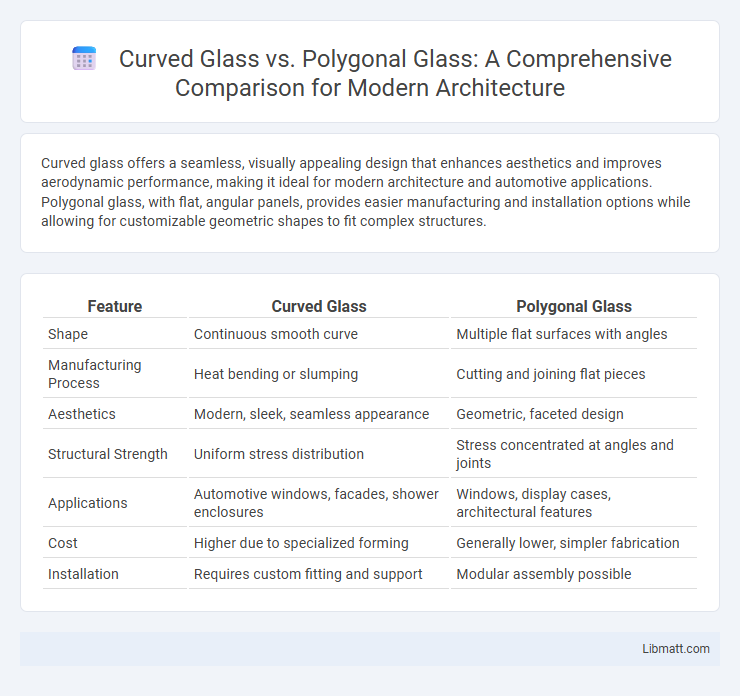

Curved glass offers a seamless, visually appealing design that enhances aesthetics and improves aerodynamic performance, making it ideal for modern architecture and automotive applications. Polygonal glass, with flat, angular panels, provides easier manufacturing and installation options while allowing for customizable geometric shapes to fit complex structures.

Table of Comparison

| Feature | Curved Glass | Polygonal Glass |

|---|---|---|

| Shape | Continuous smooth curve | Multiple flat surfaces with angles |

| Manufacturing Process | Heat bending or slumping | Cutting and joining flat pieces |

| Aesthetics | Modern, sleek, seamless appearance | Geometric, faceted design |

| Structural Strength | Uniform stress distribution | Stress concentrated at angles and joints |

| Applications | Automotive windows, facades, shower enclosures | Windows, display cases, architectural features |

| Cost | Higher due to specialized forming | Generally lower, simpler fabrication |

| Installation | Requires custom fitting and support | Modular assembly possible |

Introduction to Curved Glass and Polygonal Glass

Curved glass features a smooth, continuous bend that enhances architectural aesthetics and provides improved structural integrity compared to polygonal glass, which consists of flat, angular panes joined at defined edges. Your choice between curved and polygonal glass affects light diffusion, design flexibility, and installation complexity, with curved glass offering seamless contours ideal for modern designs and polygonal glass providing more straightforward fabrication and assembly. Both materials are pivotal in contemporary construction but serve distinct functional and visual purposes based on their geometric properties.

Key Differences Between Curved and Polygonal Glass

Curved glass features smooth, continuous curves that enhance aesthetics and improve structural integrity by distributing stress evenly. Polygonal glass consists of flat panels joined at angles, offering more design flexibility but creating visible seams and potential stress points. Your choice depends on the desired architectural effect, with curved glass providing seamless elegance and polygonal glass enabling geometric complexity.

Aesthetic Appeal: Curved Glass vs Polygonal Glass

Curved glass offers a sleek, modern aesthetic with smooth, continuous lines that enhance architectural fluidity and visual harmony. Polygonal glass provides a dynamic, geometric appearance, creating bold, angular facades that emphasize structural complexity and contemporary edge. Choosing between curved and polygonal glass depends on desired visual impact, design intent, and integration with overall building aesthetics.

Structural Strength and Durability Comparison

Curved glass offers enhanced structural strength due to its ability to evenly distribute stress across its surface, reducing the likelihood of cracks and breakage compared to polygonal glass with sharp angles. The smooth, continuous surface of curved glass improves durability by minimizing weak points where fractures typically initiate in polygonal panels. Your choice of curved glass can provide superior resistance to environmental pressures and mechanical impacts in architectural applications.

Design Flexibility and Applications

Curved glass offers superior design flexibility due to its ability to create seamless, flowing surfaces that enhance aesthetics in automotive, architectural, and interior design applications. Polygonal glass, composed of flat panels joined at angles, provides more straightforward fabrication but limits the smooth, continuous forms achievable with curved glass. Your choice depends on the desired visual effect and structural requirements, with curved glass ideal for innovative, fluid designs and polygonal glass suited for angular, geometric structures.

Manufacturing Process and Cost Analysis

Curved glass manufacturing involves complex processes like heating and bending flat glass sheets over molds, requiring precise temperature control and specialized equipment, which significantly increases production costs compared to polygonal glass. Polygonal glass, typically produced through cutting and assembling flat panes at distinct angles, benefits from simpler fabrication with lower material waste and reduced labor expenses. The higher capital investment and time-intensive nature of curved glass result in substantially greater overall costs in contrast to the more economical polygonal glass solutions.

Energy Efficiency and Environmental Impact

Curved glass offers superior energy efficiency due to its ability to minimize air leakage and provide better insulation, reducing heating and cooling costs. Polygonal glass, with its multiple edges and joints, often results in higher thermal bridging, leading to greater energy loss and increased environmental impact. By choosing curved glass, you can enhance your building's sustainability and reduce its carbon footprint.

Safety Considerations for Curved and Polygonal Glass

Curved glass offers enhanced structural strength due to its shape, dispersing impact forces more evenly than polygonal glass, which features multiple angled edges that can create stress points prone to cracking. Safety glazing treatments such as tempered or laminated glass are crucial for both types to prevent hazardous shattering, especially in high-traffic or impact-prone environments. When selecting glass for your project, consider curved glass for applications requiring better impact resistance and aesthetic smoothness while ensuring proper safety certifications and installation standards are met for either glass type.

Market Trends and Consumer Preferences

Curved glass is gaining traction in the market due to its aesthetic appeal and superior structural integrity, making it favored for high-end architectural and automotive applications. Polygonal glass remains popular in customizable, cost-efficient projects where flat panels are easier to manufacture and install. Consumer preferences show a growing demand for innovative designs, driving the increased adoption of curved glass in luxury products and smart technology devices.

Choosing the Right Glass: Factors to Consider

Curved glass offers seamless aesthetics and enhanced structural strength, ideal for modern architectural designs requiring smooth contours. Polygonal glass provides versatility in shape customization, allowing sharp angles and geometric patterns suited for intricate facades. When choosing your glass, consider factors such as design requirements, load-bearing capacity, and visual appeal to ensure optimal performance and style.

curved glass vs polygonal glass Infographic

libmatt.com

libmatt.com