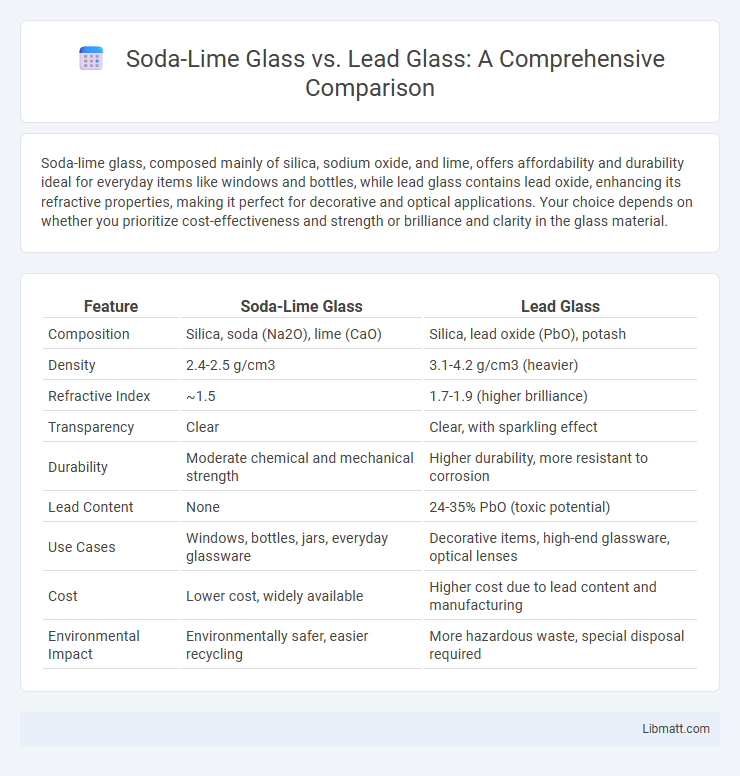

Soda-lime glass, composed mainly of silica, sodium oxide, and lime, offers affordability and durability ideal for everyday items like windows and bottles, while lead glass contains lead oxide, enhancing its refractive properties, making it perfect for decorative and optical applications. Your choice depends on whether you prioritize cost-effectiveness and strength or brilliance and clarity in the glass material.

Table of Comparison

| Feature | Soda-Lime Glass | Lead Glass |

|---|---|---|

| Composition | Silica, soda (Na2O), lime (CaO) | Silica, lead oxide (PbO), potash |

| Density | 2.4-2.5 g/cm3 | 3.1-4.2 g/cm3 (heavier) |

| Refractive Index | ~1.5 | 1.7-1.9 (higher brilliance) |

| Transparency | Clear | Clear, with sparkling effect |

| Durability | Moderate chemical and mechanical strength | Higher durability, more resistant to corrosion |

| Lead Content | None | 24-35% PbO (toxic potential) |

| Use Cases | Windows, bottles, jars, everyday glassware | Decorative items, high-end glassware, optical lenses |

| Cost | Lower cost, widely available | Higher cost due to lead content and manufacturing |

| Environmental Impact | Environmentally safer, easier recycling | More hazardous waste, special disposal required |

Introduction to Soda-Lime Glass and Lead Glass

Soda-lime glass is the most common type of glass, composed primarily of silica, soda, and lime, known for its durability and affordability in everyday applications like windows and bottles. Lead glass, also called lead crystal, contains a significant amount of lead oxide, which increases its density, brilliance, and refractive index, making it ideal for decorative items and high-quality optical products. Understanding the differences in composition and properties helps you choose the right glass type for your specific needs, whether for practical use or ornamental purposes.

Historical Background and Development

Soda-lime glass, developed around 1500 BCE, became the most common glass type due to its low production cost and widespread availability of raw materials like silica, soda ash, and limestone. Lead glass, introduced in the late 17th century by English chemist George Ravenscroft, features added lead oxide to enhance refractive qualities and workability, revolutionizing decorative glassware. The historical shift from soda-lime to lead glass marked significant advancements in optical clarity and craftsmanship during the Renaissance and Industrial Age.

Chemical Composition Differences

Soda-lime glass primarily consists of silica (SiO2), sodium oxide (Na2O), and calcium oxide (CaO), providing durability and affordability. Lead glass contains a significant proportion of lead oxide (PbO), which enhances its density, refractive index, and brilliance compared to soda-lime glass. Your choice between these two depends on the desired optical properties and chemical resistance for specific applications.

Physical Properties Comparison

Soda-lime glass typically has a density of about 2.5 g/cm3 and a lower refractive index around 1.52, while lead glass exhibits a higher density ranging from 3.1 to 4.0 g/cm3 and a refractive index up to 1.85, contributing to its brilliance and weight. Lead glass also features increased softness and lower melting points compared to the harder, more durable soda-lime glass, which offers higher resistance to thermal shock. The physical contrast between their chemical compositions directly impacts applications, with soda-lime commonly used for windows and bottles due to its strength and clarity, whereas lead glass is preferred for decorative items and radiation shielding.

Optical and Aesthetic Qualities

Soda-lime glass features moderate optical clarity and a neutral appearance, making it suitable for everyday applications where cost efficiency and durability are priorities. Lead glass, enriched with lead oxide, offers exceptional brilliance and higher refractive index, resulting in superior light dispersion and a sparkling aesthetic ideal for decorative items and fine glassware. The increased density of lead glass enhances its weight and clarity, providing a distinct visual depth and enhanced color contrast compared to soda-lime glass.

Common Applications and Uses

Soda-lime glass is widely used in everyday applications such as windows, bottles, and jars due to its affordability, durability, and ease of manufacture. Lead glass, also known as crystal glass, is commonly used in decorative items, fine glassware, and optical instruments thanks to its high refractive index and enhanced clarity. You will often find lead glass in luxury products like chandeliers and high-end drinkware, while soda-lime glass dominates mass-market containers and construction materials.

Health and Environmental Considerations

Soda-lime glass is favored for its non-toxic composition and recyclability, making it a safer choice for health and the environment compared to lead glass, which contains lead oxide that poses potential health risks through lead exposure. Lead glass production and disposal can lead to soil and water contamination, raising significant environmental concerns. You can reduce health hazards and environmental impact by choosing soda-lime glass for everyday use and proper recycling practices.

Manufacturing Processes and Costs

Soda-lime glass is manufactured using abundant raw materials such as silica, soda ash, and limestone, making its production cost-effective and suitable for mass production. Lead glass involves adding lead oxide during melting, which increases melting temperatures and energy consumption, resulting in higher manufacturing costs. The simpler process and lower material expenses of soda-lime glass contribute to its widespread use in everyday glass products compared to the more expensive, specialized lead glass.

Durability and Maintenance

Soda-lime glass offers high durability with excellent resistance to chemical corrosion and moderate mechanical stress, making it suitable for everyday use and easy maintenance. Lead glass, while less durable due to its higher density and softer structure, requires more careful handling to prevent scratches and chips but offers superior clarity and brilliance. Both types benefit from regular cleaning with mild detergents to maintain their appearance, though soda-lime glass generally withstands more frequent washing and harsher conditions.

Choosing the Right Glass Type

Choosing the right glass type depends on your specific needs, as soda-lime glass offers durability, affordability, and excellent chemical resistance ideal for everyday use and window panes. Lead glass contains lead oxide, providing superior brilliance and weight, making it perfect for decorative items and fine glassware requiring enhanced refractive qualities. Consider factors like cost, clarity, and usage context to ensure your selection aligns with both practical and aesthetic requirements.

Soda-lime glass vs lead glass Infographic

libmatt.com

libmatt.com