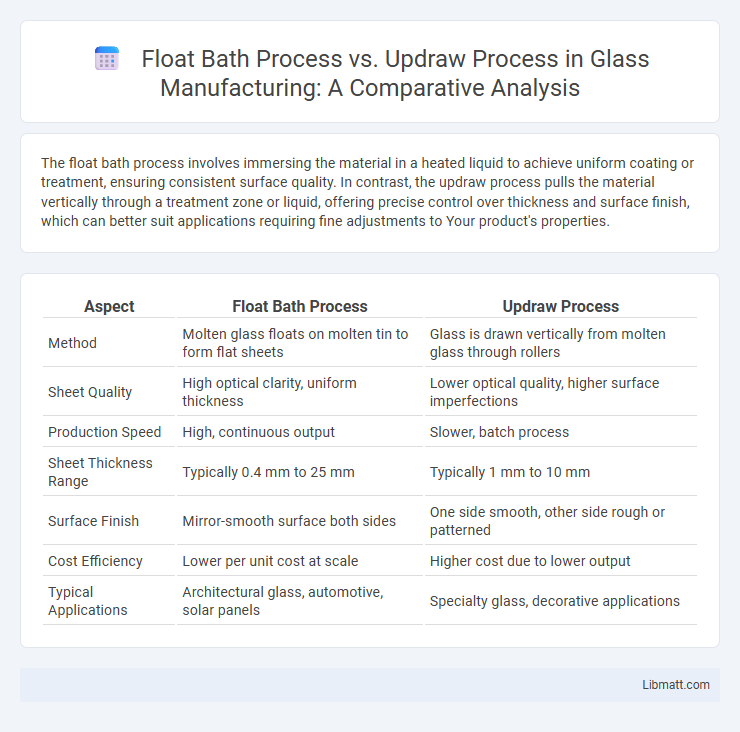

The float bath process involves immersing the material in a heated liquid to achieve uniform coating or treatment, ensuring consistent surface quality. In contrast, the updraw process pulls the material vertically through a treatment zone or liquid, offering precise control over thickness and surface finish, which can better suit applications requiring fine adjustments to Your product's properties.

Table of Comparison

| Aspect | Float Bath Process | Updraw Process |

|---|---|---|

| Method | Molten glass floats on molten tin to form flat sheets | Glass is drawn vertically from molten glass through rollers |

| Sheet Quality | High optical clarity, uniform thickness | Lower optical quality, higher surface imperfections |

| Production Speed | High, continuous output | Slower, batch process |

| Sheet Thickness Range | Typically 0.4 mm to 25 mm | Typically 1 mm to 10 mm |

| Surface Finish | Mirror-smooth surface both sides | One side smooth, other side rough or patterned |

| Cost Efficiency | Lower per unit cost at scale | Higher cost due to lower output |

| Typical Applications | Architectural glass, automotive, solar panels | Specialty glass, decorative applications |

Introduction to Glass Manufacturing Processes

The float bath process involves floating molten glass on a bed of molten tin, producing flat and uniform glass sheets with high optical quality, widely used in architectural and automotive glass production. In contrast, the updraw process pulls molten glass vertically from a molten liquid surface, allowing precise thickness control in the manufacture of specialty glass products. Both processes are fundamental in glass manufacturing, with the float bath process favored for large-scale flat glass and the updraw process suited for high-quality, smaller-scale applications.

Overview of Float Bath Process

The Float Bath Process involves melting glass and distributing it evenly onto a molten tin bath, forming a perfectly flat glass sheet due to gravity and surface tension. This method ensures consistent thickness and superior surface quality, making it ideal for high-precision applications like architectural and automotive glass. You benefit from uniform strength and optical clarity that result from this controlled manufacturing approach.

Overview of Updraw Glass Process

The Updraw Glass Process involves continuously drawing molten glass upward through a vertical slot, resulting in a high-quality, uniform thickness sheet ideal for precision applications. Unlike the Float Bath Process, which floats molten glass on a bed of molten tin to produce flat glass, the Updraw Process emphasizes minimal surface defects and superior optical clarity. Understanding the Updraw Glass Process can help you select the right manufacturing technique for specialized glass products requiring exceptional dimensional control.

Key Differences Between Float Bath and Updraw Processes

The float bath process involves molten glass floating on a bath of molten tin, producing a uniformly flat glass sheet with high optical quality, while the updraw process pulls molten glass vertically upward through a narrow slit to form glass ribbons. Key differences include the float bath's horizontal flow yielding consistent thickness and minimal distortion, contrasted with the updraw process's vertical pulling which can introduce variations in thickness and surface imperfections. The float bath method dominates in large-scale production due to superior surface quality and efficiency, whereas the updraw process is typically used for specialized or smaller-scale applications.

Advantages of Float Bath Process

The Float Bath Process offers superior surface quality and uniform thickness control compared to the Updraw Process, resulting in smoother and defect-free glass sheets ideal for architectural and automotive applications. It provides higher production speeds and better dimensional accuracy, minimizing material waste and lowering manufacturing costs. Your choice of the Float Bath Process ensures enhanced consistency and scalability in glass production, meeting stringent industry standards efficiently.

Advantages of the Updraw Process

The Updraw process offers superior control over film thickness and uniformity compared to the Float bath process, making it ideal for high-precision applications. This process minimizes contamination risks by reducing exposure to molten metals, which enhances the overall quality of the final product. Increased production speed and energy efficiency also make the Updraw process more cost-effective for large-scale manufacturing.

Limitations and Challenges of Each Process

The float bath process faces limitations such as maintaining a consistent molten glass surface temperature and controlling contamination, which can affect the uniformity of the glass thickness. In contrast, the updraw process encounters challenges with precise tension control and vertical alignment, making it difficult to produce large, defect-free glass sheets. Understanding these limitations helps optimize Your choice based on required glass quality and production scale.

Applications of Float Bath and Updraw Glass

The float bath process produces high-quality, distortion-free flat glass primarily used in automotive windows, architectural panels, and solar panels due to its smooth surface and uniform thickness. The updraw process is suited for manufacturing specialty glass such as LCD screens and optical glass, where precision and controlled thickness are critical. Your choice between these methods depends on the specific glass application requirements and desired optical properties.

Economic and Environmental Considerations

The float bath process typically incurs higher initial capital costs due to the extensive glass handling equipment but offers lower operational energy consumption by maintaining a stable molten metal surface, enhancing economic efficiency over time. The updraw process reduces raw material waste through precise control and minimized glass thickness variability, contributing to better raw material utilization and environmental sustainability. Both processes aim to lower emissions and reduce energy consumption, but the float bath process generally produces fewer airborne contaminants, making it more favorable from an environmental perspective.

Choosing the Right Process for Glass Production

Selecting the right glass production method hinges on your specific needs for quality, efficiency, and product application. The float bath process provides a smooth, uniform glass surface ideal for architectural and automotive uses, while the updraw process excels in producing thinner, high-purity glass suited for specialty applications like LCD panels. Evaluating factors such as production volume, glass thickness requirements, and cost constraints can guide your decision to optimize both performance and profitability.

Float bath process vs updraw process Infographic

libmatt.com

libmatt.com