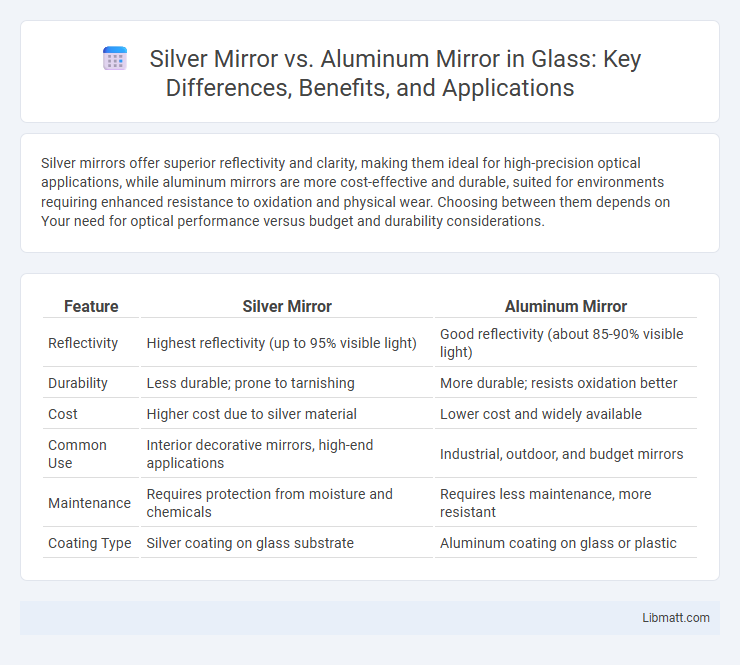

Silver mirrors offer superior reflectivity and clarity, making them ideal for high-precision optical applications, while aluminum mirrors are more cost-effective and durable, suited for environments requiring enhanced resistance to oxidation and physical wear. Choosing between them depends on Your need for optical performance versus budget and durability considerations.

Table of Comparison

| Feature | Silver Mirror | Aluminum Mirror |

|---|---|---|

| Reflectivity | Highest reflectivity (up to 95% visible light) | Good reflectivity (about 85-90% visible light) |

| Durability | Less durable; prone to tarnishing | More durable; resists oxidation better |

| Cost | Higher cost due to silver material | Lower cost and widely available |

| Common Use | Interior decorative mirrors, high-end applications | Industrial, outdoor, and budget mirrors |

| Maintenance | Requires protection from moisture and chemicals | Requires less maintenance, more resistant |

| Coating Type | Silver coating on glass substrate | Aluminum coating on glass or plastic |

Introduction to Silver and Aluminum Mirrors

Silver mirrors provide superior reflectivity, capturing up to 95% of visible light, making them ideal for applications requiring high optical clarity. Aluminum mirrors, while reflecting around 85-90% of light, offer greater durability and resistance to oxidation, suited for outdoor and industrial uses. Understanding the differences helps you choose the right mirror material based on reflectivity needs and environmental conditions.

Material Composition and Manufacturing Process

Silver mirrors consist of a silver coating applied through chemical or electroplating processes onto a glass substrate, providing high reflectivity in the visible spectrum due to silver's superior optical properties. Aluminum mirrors use an aluminum layer deposited via vacuum deposition or sputtering techniques onto glass, offering enhanced durability and resistance to oxidation with slightly lower reflectivity than silver. The manufacturing process for silver mirrors demands careful protection against tarnishing, while aluminum mirrors benefit from protective dielectric coatings that improve longevity and environmental resistance.

Reflectivity: Silver Mirrors vs Aluminum Mirrors

Silver mirrors offer superior reflectivity, typically reflecting up to 95% of visible light, making them ideal for applications requiring high optical clarity. Aluminum mirrors reflect around 85% to 90% of visible light but perform better in ultraviolet and infrared spectrums. For your projects demanding maximum brightness and color accuracy, silver mirrors provide a noticeable advantage over aluminum mirrors.

Durability and Resistance to Tarnishing

Silver mirrors provide superior reflectivity but are more prone to tarnishing due to their silver coating reacting with sulfur compounds in the air, requiring protective layers to enhance durability. Aluminum mirrors offer excellent resistance to corrosion and tarnishing, making them more durable in humid or outdoor environments. Your choice depends on the balance between optical quality and maintenance needs for the mirror's intended use.

Cost Comparison: Silver vs Aluminum Mirrors

Silver mirrors typically have a higher cost than aluminum mirrors due to the expense of silver as a raw material and the complex manufacturing process involved in silver coating. Aluminum mirrors offer a more budget-friendly option, making them ideal for large-scale applications or projects with cost constraints. While silver mirrors provide superior reflectivity and durability, aluminum mirrors deliver acceptable performance at a significantly lower price point.

Applications and Common Uses

Silver mirrors are widely used in high-end optical devices, scientific instruments, and decorative applications due to their superior reflectivity in the visible spectrum and excellent color fidelity. Aluminum mirrors are commonly found in industrial, automotive, and outdoor applications where durability and resistance to oxidation are crucial, despite having slightly lower reflectivity than silver. Your choice between the two depends on the requirement for either optical performance or environmental resilience in specific applications.

Optical Clarity and Image Quality

Silver mirrors offer superior optical clarity and image quality due to their high reflectivity across the visible spectrum, producing bright, true-to-color reflections. Aluminum mirrors, while more durable and cost-effective, typically exhibit slightly lower reflectance and may introduce minor distortions or color shifts. For Your applications requiring precise, sharp images, silver mirrors are generally the preferred choice.

Maintenance and Cleaning Requirements

Silver mirrors require gentle cleaning with non-abrasive, ammonia-free solutions to prevent tarnishing and corrosion, maintaining their high reflectivity over time. Aluminum mirrors offer greater durability and resist oxidation, allowing for easier maintenance using standard glass cleaners without special precautions. Choosing an aluminum mirror can reduce your cleaning effort, but silver mirrors provide superior reflectance if properly cared for.

Environmental Impact of Mirror Materials

Silver mirrors have a higher environmental impact due to the mining and refining processes required for silver, which consume significant energy and produce hazardous waste. Aluminum mirrors are generally more eco-friendly as aluminum is more abundant, recyclable, and requires less energy for production and recycling. Choosing aluminum mirrors reduces carbon footprint and promotes sustainability in mirror manufacturing.

Choosing the Right Mirror for Your Needs

Silver mirrors offer superior reflectivity and true color accuracy, making them ideal for high-precision applications like makeup or scientific instruments. Aluminum mirrors are more durable and cost-effective, suitable for outdoor use or where robustness is essential. Assess your specific needs for clarity, durability, and budget to choose the right mirror for your requirements.

Silver mirror vs aluminum mirror Infographic

libmatt.com

libmatt.com