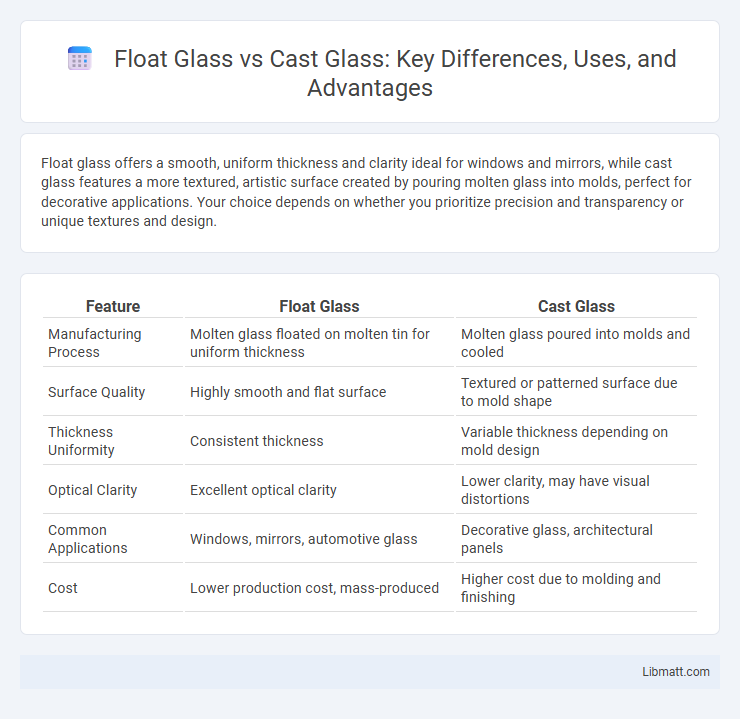

Float glass offers a smooth, uniform thickness and clarity ideal for windows and mirrors, while cast glass features a more textured, artistic surface created by pouring molten glass into molds, perfect for decorative applications. Your choice depends on whether you prioritize precision and transparency or unique textures and design.

Table of Comparison

| Feature | Float Glass | Cast Glass |

|---|---|---|

| Manufacturing Process | Molten glass floated on molten tin for uniform thickness | Molten glass poured into molds and cooled |

| Surface Quality | Highly smooth and flat surface | Textured or patterned surface due to mold shape |

| Thickness Uniformity | Consistent thickness | Variable thickness depending on mold design |

| Optical Clarity | Excellent optical clarity | Lower clarity, may have visual distortions |

| Common Applications | Windows, mirrors, automotive glass | Decorative glass, architectural panels |

| Cost | Lower production cost, mass-produced | Higher cost due to molding and finishing |

Introduction to Float Glass and Cast Glass

Float glass is produced by floating molten glass on a bed of molten metal, typically tin, resulting in a smooth, uniform surface ideal for windows and mirrors. Cast glass is made by pouring molten glass into molds, allowing for varied thickness and shapes often used in artistic and architectural applications. Understanding these manufacturing methods helps you select the right glass type for your specific design or functional needs.

Manufacturing Processes: Float vs Cast Glass

Float glass is produced by floating molten glass on a bed of molten metal, typically tin, resulting in a uniform and smooth surface with consistent thickness. Cast glass involves pouring molten glass into molds where it cools and solidifies, allowing for thicker, more textured, and uniquely shaped panels. Understanding these manufacturing processes helps you choose between the precision of float glass and the artistic versatility of cast glass.

Key Physical Properties Comparison

Float glass offers uniform thickness, smooth surfaces, and high optical clarity due to its manufacturing process on molten metal, providing excellent transparency and consistent mechanical strength. Cast glass, formed by pouring molten glass into molds, typically exhibits textured surfaces and variable thickness, resulting in unique visual effects but lower optical clarity and strength compared to float glass. Your choice depends on whether you prioritize precision and clarity (float glass) or artistic texture and form (cast glass) in your application.

Visual and Aesthetic Differences

Float glass offers a smooth, flat surface with uniform clarity and minimal distortion, making it ideal for applications requiring clean, modern aesthetics. Cast glass features a textured, often irregular surface that can create unique visual effects and add depth through light diffusion, enhancing decorative appeal. Your choice depends on whether you prioritize sleek transparency or artistic texture in your design.

Strength and Durability Analysis

Float glass offers uniform thickness and smooth surfaces due to its controlled manufacturing process, resulting in consistent strength and moderate durability ideal for standard architectural applications. Cast glass exhibits variable thickness and natural surface textures, enhancing its impact resistance and durability, making it suitable for decorative features requiring both strength and aesthetic appeal. Your choice depends on whether you prioritize the uniform strength and clarity of float glass or the robust, artistic qualities of cast glass for your project.

Common Applications of Float and Cast Glass

Float glass is widely used in windows, doors, and storefronts due to its smooth surface and uniform thickness, making it ideal for architectural and automotive applications. Cast glass is favored for decorative purposes, such as art installations, textured wall panels, and custom furniture, where unique patterns and thickness variations add aesthetic value. Both types serve complementary roles in construction and design, with float glass prioritizing clarity and strength, and cast glass emphasizing artistic expression.

Energy Efficiency and Insulation

Float glass offers superior energy efficiency due to its uniform thickness and smooth surface, which enhances the performance of low-emissivity coatings that reduce heat transfer. Cast glass, with its irregular texture and thickness, typically provides less effective insulation and higher thermal conductivity, leading to increased energy loss. In energy-efficient building applications, float glass is preferred for minimizing heat gain and loss, contributing to lower heating and cooling costs.

Cost Considerations

Float glass generally offers lower production costs due to its continuous manufacturing process, resulting in economies of scale. Cast glass requires more labor-intensive techniques and longer cooling times, increasing material and operational expenses. Budget-conscious projects often favor float glass for cost efficiency, while cast glass is reserved for custom or artistic applications despite its higher price.

Sustainability and Environmental Impact

Float glass production uses continuous melting and rolling processes, resulting in less energy consumption and lower emissions compared to cast glass, which involves slower, more energy-intensive cooling cycles. Float glass recycling is highly efficient, contributing to significant reductions in raw material extraction and landfill waste. Cast glass often demands more raw materials and produces more manufacturing waste, leading to a higher environmental footprint relative to float glass.

Choosing the Right Glass for Your Project

Float glass offers a smooth, uniform surface ideal for windows and large architectural panels, ensuring clarity and strength at a competitive cost. Cast glass provides unique textures and artistic effects, making it perfect for decorative applications, custom installations, and projects requiring light diffusion. Selecting between float and cast glass depends on the balance between functional requirements and aesthetic preferences, with float glass favored for structural purposes and cast glass chosen for design-driven projects.

float glass vs cast glass Infographic

libmatt.com

libmatt.com