Wired glass offers enhanced fire resistance and security by embedding a metal mesh within the glass, making it less likely to shatter into sharp pieces, while laminated glass consists of multiple layers bonded with a plastic interlayer, providing superior impact resistance and sound insulation. Your choice depends on whether safety against fire or protection from breakage and noise reduction is the primary concern.

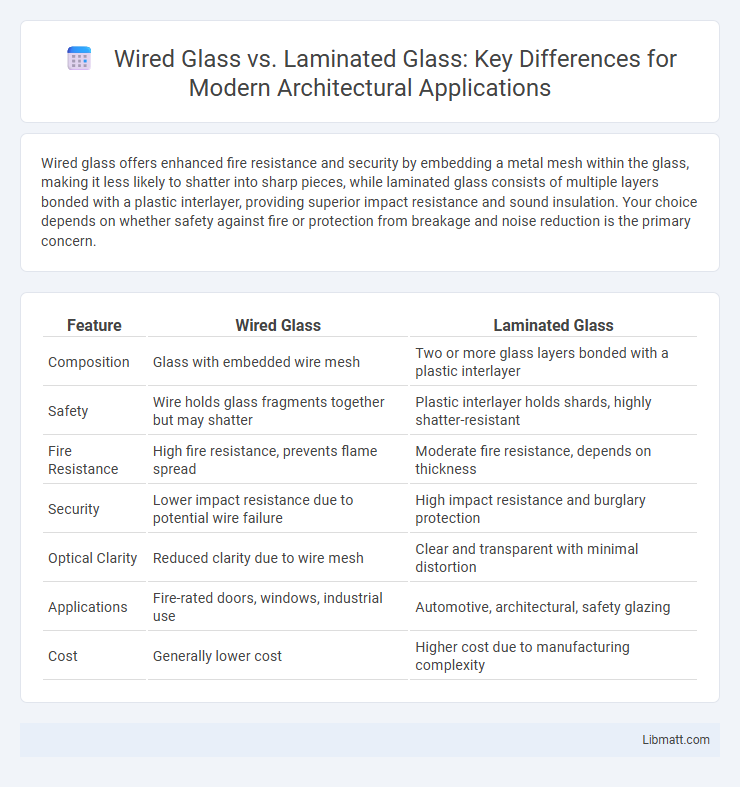

Table of Comparison

| Feature | Wired Glass | Laminated Glass |

|---|---|---|

| Composition | Glass with embedded wire mesh | Two or more glass layers bonded with a plastic interlayer |

| Safety | Wire holds glass fragments together but may shatter | Plastic interlayer holds shards, highly shatter-resistant |

| Fire Resistance | High fire resistance, prevents flame spread | Moderate fire resistance, depends on thickness |

| Security | Lower impact resistance due to potential wire failure | High impact resistance and burglary protection |

| Optical Clarity | Reduced clarity due to wire mesh | Clear and transparent with minimal distortion |

| Applications | Fire-rated doors, windows, industrial use | Automotive, architectural, safety glazing |

| Cost | Generally lower cost | Higher cost due to manufacturing complexity |

Introduction to Wired Glass and Laminated Glass

Wired glass features a metal mesh embedded within the glass, enhancing fire resistance and preventing shattering during impacts. Laminated glass consists of two or more glass layers bonded by an interlayer, typically polyvinyl butyral (PVB), offering superior safety by holding shards together upon breakage. Both materials serve different safety and security purposes, with wired glass commonly used in fire-rated assemblies and laminated glass preferred for impact resistance and sound insulation.

Composition and Manufacturing Processes

Wired glass consists of a layer of glass embedded with a metal wire mesh during the manufacturing process to enhance fire resistance and prevent shattering. Laminated glass is made by bonding two or more layers of glass with an interlayer, typically polyvinyl butyral (PVB), through heat and pressure to improve safety and sound insulation. The manufacturing of wired glass involves embedding wire mesh within the molten glass, whereas laminated glass production involves sandwiching and curing layers for structural integrity and impact resistance.

Safety Performance Comparison

Wired glass features a metal mesh embedded within the glass pane, providing enhanced fire resistance by holding shards together during breakage, but it tends to shatter into sharp fragments posing injury risks. Laminated glass consists of multiple layers bonded with an interlayer, typically polyvinyl butyral (PVB), which maintains structural integrity upon impact, significantly reducing the likelihood of penetration and minimizing injury hazards. In safety performance, laminated glass surpasses wired glass by offering superior impact resistance, shatter containment, and protection against forced entry.

Impact Resistance and Durability

Wired glass offers moderate impact resistance due to its embedded wire mesh, which helps hold shards together upon breakage but can still shatter under strong forces. Laminated glass provides superior durability and impact resistance by bonding multiple layers of glass with a plastic interlayer that absorbs shocks and prevents penetration. When choosing glass for safety, laminated glass better protects your environment by maintaining integrity under high-impact conditions.

Fire and Heat Resistance Capabilities

Wired glass offers superior fire resistance due to its embedded wire mesh, which maintains structural integrity and prevents shattering under extreme heat, making it ideal for fire-rated assemblies. Laminated glass also provides excellent fire and heat resistance by holding glass fragments together with a resilient interlayer, ensuring safety and reducing smoke penetration. Both types comply with stringent fire safety standards, but wired glass is often preferred in applications requiring enhanced fire containment and thermal protection.

Applications in Modern Architecture

Wired glass is commonly used in fire-rated doors and windows due to its enhanced fire resistance and safety during breakage, while laminated glass is favored for its superior impact resistance and noise reduction in curtain walls and facades. Modern architecture often employs laminated glass in skylights and balustrades to ensure durability and occupant safety without compromising transparency. Both materials support sustainable building practices by contributing to energy efficiency and occupant protection in commercial and residential designs.

Acoustic and Thermal Insulation Properties

Wired glass offers limited acoustic insulation due to its single-pane construction and lacks significant thermal resistance compared to laminated glass. Laminated glass contains interlayers that effectively reduce sound transmission and provide enhanced thermal insulation by minimizing heat transfer. The multilayer structure of laminated glass makes it superior for applications requiring noise reduction and energy efficiency.

Cost Differences and Budget Considerations

Wired glass typically costs less than laminated glass, making it a budget-friendly option for projects with tight financial constraints. Laminated glass offers superior safety and sound insulation but comes at a higher price due to its multiple layers and interlayer materials. Understanding your specific needs and budget will help determine which glass type offers the best value for your investment.

Regulatory Standards and Building Codes

Wired glass and laminated glass are subject to different regulatory standards and building codes, which can impact their permissible use in construction projects. Wired glass often meets fire-resistance requirements due to its embedded wire mesh that provides added structural integrity during fires, but it typically falls short in impact safety standards compared to laminated glass. Your choice should align with local building codes such as those outlined by the International Building Code (IBC), which increasingly favor laminated glass for safety glazing requirements in areas prone to impact hazards.

Choosing the Right Glass for Your Project

Wired glass offers enhanced fire resistance and security through its embedded metal mesh, making it ideal for industrial settings requiring durability against heat and impact. Laminated glass consists of multiple layers bonded with a plastic interlayer, providing superior safety by holding shards together upon breakage and offering better sound insulation. Choose laminated glass for projects prioritizing occupant safety and noise reduction, while wired glass suits applications demanding fire protection and structural strength.

wired glass vs laminated glass Infographic

libmatt.com

libmatt.com