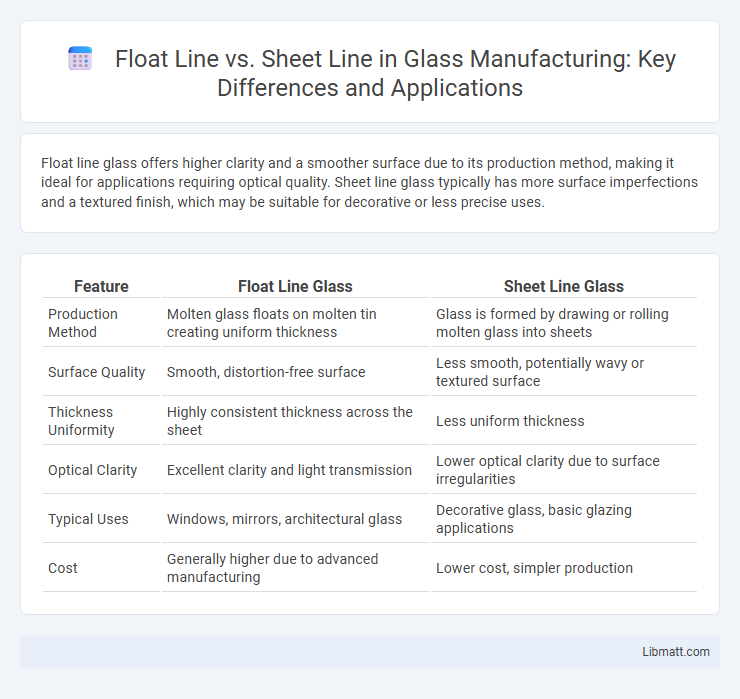

Float line glass offers higher clarity and a smoother surface due to its production method, making it ideal for applications requiring optical quality. Sheet line glass typically has more surface imperfections and a textured finish, which may be suitable for decorative or less precise uses.

Table of Comparison

| Feature | Float Line Glass | Sheet Line Glass |

|---|---|---|

| Production Method | Molten glass floats on molten tin creating uniform thickness | Glass is formed by drawing or rolling molten glass into sheets |

| Surface Quality | Smooth, distortion-free surface | Less smooth, potentially wavy or textured surface |

| Thickness Uniformity | Highly consistent thickness across the sheet | Less uniform thickness |

| Optical Clarity | Excellent clarity and light transmission | Lower optical clarity due to surface irregularities |

| Typical Uses | Windows, mirrors, architectural glass | Decorative glass, basic glazing applications |

| Cost | Generally higher due to advanced manufacturing | Lower cost, simpler production |

Introduction to Float Line and Sheet Line

Float line technology produces flat, uniform glass by floating molten glass on a bed of molten tin, ensuring high optical quality and minimal distortion. Sheet line manufacturing involves drawing molten glass vertically or horizontally through rollers to form sheets, resulting in glass with more surface imperfections and variable thickness. Float lines dominate modern glass production due to superior clarity, consistent thickness, and cost efficiency compared to traditional sheet lines.

Key Differences Between Float Line and Sheet Line

Float line glass is produced by floating molten glass on a bed of molten tin, resulting in smooth, uniform sheets with consistent thickness and high optical clarity. Sheet line glass, made by rolling molten glass into sheets, often exhibits surface imperfections and variable thickness, making it less clear and less uniform than float glass. Float glass is preferred in modern architectural and automotive applications due to its superior quality, while sheet glass is mostly used in older or less demanding applications.

Understanding the Float Glass Production Process

The float line method produces glass by floating molten glass on a bed of molten metal, typically tin, resulting in uniform thickness and smooth surfaces essential for high-quality glass sheets. In contrast, the sheet line process involves drawing molten glass vertically or horizontally through rollers, which can lead to variations in thickness and surface imperfections. Understanding these differences helps you choose the best glass type for applications requiring precision and clarity.

Overview of Sheet Glass Manufacturing

Sheet glass manufacturing involves forming flat glass by drawing molten glass vertically through rollers, known as the sheet line process, producing glass with varied thickness but often visible surface imperfections. The float line process, in contrast, floats molten glass on a bed of molten tin, ensuring uniform thickness and exceptional optical clarity, making it the industry standard for high-quality flat glass production. Understanding both methods helps you appreciate differences in surface quality, thickness uniformity, and application suitability in architectural and automotive glazing.

Historical Development: Float Line vs Sheet Line

The historical development of float line technology began in the 1950s with the invention of the float glass process by Alastair Pilkington, revolutionizing the glass industry by producing flat, uniform, and high-quality glass sheets directly on a molten tin bath. In contrast, sheet line methods emerged earlier, relying on rolling or drawing molten glass into sheets, which often resulted in less uniform thickness and optical distortions. The float line's innovation significantly improved production efficiency and product quality, eventually supplanting traditional sheet line techniques in most commercial applications.

Advantages of Float Line Glass

Float line glass offers superior optical clarity and a smooth, uniform surface due to its controlled manufacturing process. Your projects benefit from higher strength and consistent thickness, making float glass ideal for architectural and automotive applications. Enhanced durability and improved resistance to thermal stress distinguish float line glass over traditional sheet line alternatives.

Benefits and Limitations of Sheet Line Glass

Sheet line glass offers consistent thickness and surface quality, making it ideal for architectural applications requiring uniformity. Its manufacturing process enables the production of larger sizes compared to float glass, but it often contains more imperfections and irregularities. Reduced optical clarity and higher production costs limit its use in high-precision or decorative glazing.

Applications: Where Float and Sheet Glass are Used

Float glass is predominantly used in architectural applications such as windows, curtain walls, and automotive glass due to its smooth surface and uniform thickness. Sheet glass, with its irregular surface and variable thickness, is commonly found in older buildings, decorative applications, and interior partitions where precision is less critical. The superior optical quality of float glass makes it the preferred choice for modern construction and high-visibility installations.

Cost Comparison: Float Line vs Sheet Line

Float lines generally offer lower production costs due to continuous processing, reducing labor and energy expenses compared to sheet lines. Sheet lines involve higher operational costs because of batch processing, frequent setup changes, and increased material handling. Your choice between float line and sheet line impacts manufacturing efficiency and overall cost-effectiveness based on volume and product specifications.

Choosing the Right Glass: Factors to Consider

Choosing the right glass between float line and sheet line hinges on quality, cost, and application requirements. Float glass offers superior optical clarity and uniform thickness, making it ideal for high-precision uses like windows and automotive glass. Sheet line glass, while more affordable, often has surface imperfections and is better suited for cost-sensitive projects with less stringent optical standards.

Float line vs sheet line Infographic

libmatt.com

libmatt.com