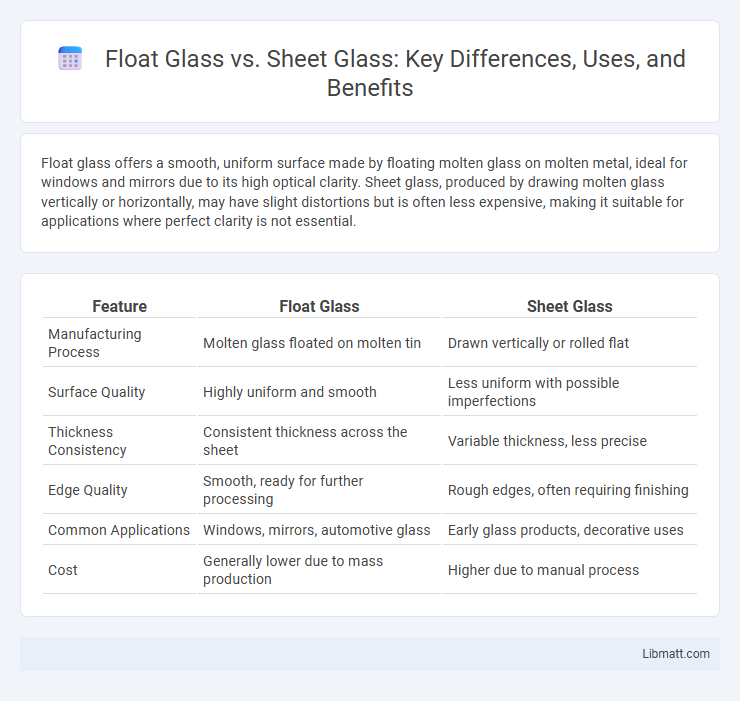

Float glass offers a smooth, uniform surface made by floating molten glass on molten metal, ideal for windows and mirrors due to its high optical clarity. Sheet glass, produced by drawing molten glass vertically or horizontally, may have slight distortions but is often less expensive, making it suitable for applications where perfect clarity is not essential.

Table of Comparison

| Feature | Float Glass | Sheet Glass |

|---|---|---|

| Manufacturing Process | Molten glass floated on molten tin | Drawn vertically or rolled flat |

| Surface Quality | Highly uniform and smooth | Less uniform with possible imperfections |

| Thickness Consistency | Consistent thickness across the sheet | Variable thickness, less precise |

| Edge Quality | Smooth, ready for further processing | Rough edges, often requiring finishing |

| Common Applications | Windows, mirrors, automotive glass | Early glass products, decorative uses |

| Cost | Generally lower due to mass production | Higher due to manual process |

Introduction to Float Glass and Sheet Glass

Float glass is produced by floating molten glass on a bed of molten metal, creating a smooth, uniform surface ideal for windows and mirrors. Sheet glass, traditionally made by rolling molten glass into sheets, often features slight imperfections and older manufacturing methods. Your choice between float glass and sheet glass impacts clarity, strength, and application in architectural or automotive projects.

Manufacturing Process Comparison

Float glass is produced by floating molten glass on a bed of molten tin, creating a smooth, uniform thickness ideal for large, flat panes. Sheet glass involves rolling molten glass into flat sheets, often resulting in slight surface imperfections and variable thickness. Your choice depends on the desired quality, with float glass offering superior clarity and consistency compared to sheet glass.

Key Physical and Chemical Properties

Float glass presents a smooth, uniform surface due to its manufacturing process, ensuring consistent thickness and clarity, whereas sheet glass often exhibits irregularities and variations in thickness. Chemically, float glass boasts higher resistance to weathering and chemical corrosion thanks to its controlled cooling, enhancing durability for windows and facades, while sheet glass is more prone to imperfections and less stable under environmental stress. Understanding these key physical and chemical properties can help you choose the right glass type for applications requiring reliability and clarity.

Surface Quality and Clarity

Float glass offers superior surface quality and clarity due to its production process, where molten glass solidifies on a bed of molten tin, resulting in an exceptionally smooth and uniform surface with minimal distortions. In contrast, sheet glass, made by rolling molten glass, often exhibits surface irregularities and optical distortions because of the uneven texture created during rolling. The enhanced surface smoothness and optical consistency of float glass make it preferable for high-precision applications requiring clear visibility.

Thickness and Size Availability

Float glass typically ranges in thickness from 2 mm to 25 mm, offering large sizes up to 3 meters by 6 meters, making it ideal for architectural and automotive applications. Sheet glass usually comes in thinner gauges, approximately 1 mm to 6 mm thick, and is available in smaller, more standardized sizes often limited to about 1 meter by 2 meters. The superior size availability and thickness range of float glass provide greater flexibility for manufacturing processes and structural uses.

Strength and Durability Differences

Float glass offers superior strength and durability compared to sheet glass due to its uniform thickness and smooth surface, which result from the controlled manufacturing process of floating molten glass on a bed of molten metal. Sheet glass, produced by rolling molten glass and cutting it into sheets, tends to have irregular thickness and surface imperfections, making it more prone to breakage and weaker under stress. The enhanced structural integrity of float glass makes it the preferred choice for applications requiring higher resistance to impact and environmental factors.

Common Applications in Industry

Float glass is widely used in the construction industry for windows, facades, and mirrors due to its smooth surface and uniform thickness. Sheet glass, often utilized in interior applications such as picture frames and cabinet doors, is manufactured through rolling or drawing processes that result in less uniformity. Both types serve essential roles in automotive glazing and photovoltaic panels, with float glass preferred for its clarity and strength in safety glass production.

Cost and Economic Considerations

Float glass typically offers lower production costs due to its automated manufacturing process, which results in consistent thickness and fewer defects compared to sheet glass. Sheet glass, produced by manually drawing molten glass, tends to be more labor-intensive and expensive, limiting its cost efficiency for large-scale applications. For economic considerations, float glass is preferred in industries requiring large volumes and uniform quality, whereas sheet glass is more suited for specialized or smaller-scale projects where aesthetics and texture are prioritized over cost.

Environmental Impact and Sustainability

Float glass production generally results in lower environmental impact compared to sheet glass due to its energy-efficient manufacturing process and higher recycling rates. Sheet glass often requires more energy and raw materials, increasing carbon emissions and resource depletion. Choosing float glass for your projects supports sustainability by reducing waste and conserving natural resources.

Choosing the Right Glass for Your Project

Float glass offers a smooth, uniform surface ideal for modern architectural designs, while sheet glass often exhibits slight imperfections due to its rolling process, making it suitable for vintage or decorative applications. Your choice should consider factors like clarity, strength, and budget, with float glass typically providing better optical quality and durability. Evaluating the specific needs of your project ensures you select the glass type that enhances both functionality and aesthetics.

Float glass vs sheet glass Infographic

libmatt.com

libmatt.com