Heat-soaked glass undergoes a specific thermal treatment to reduce the risk of spontaneous breakage caused by impurities, making it safer for structural applications, while heat-strengthened glass is tempered at a lower temperature to offer enhanced strength and resistance to thermal stress. Your choice depends on whether safety from breakage or improved durability under thermal load is the primary concern for your project.

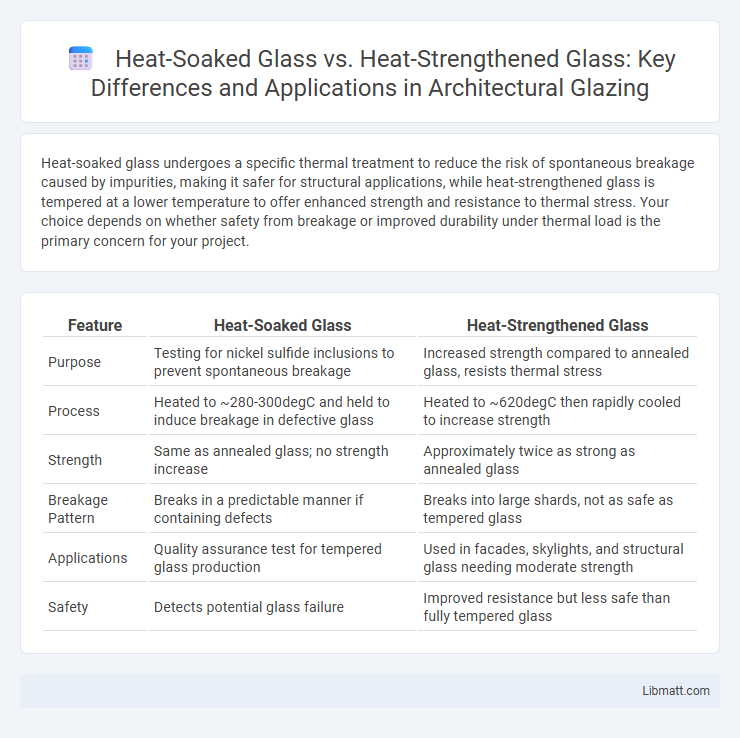

Table of Comparison

| Feature | Heat-Soaked Glass | Heat-Strengthened Glass |

|---|---|---|

| Purpose | Testing for nickel sulfide inclusions to prevent spontaneous breakage | Increased strength compared to annealed glass, resists thermal stress |

| Process | Heated to ~280-300degC and held to induce breakage in defective glass | Heated to ~620degC then rapidly cooled to increase strength |

| Strength | Same as annealed glass; no strength increase | Approximately twice as strong as annealed glass |

| Breakage Pattern | Breaks in a predictable manner if containing defects | Breaks into large shards, not as safe as tempered glass |

| Applications | Quality assurance test for tempered glass production | Used in facades, skylights, and structural glass needing moderate strength |

| Safety | Detects potential glass failure | Improved resistance but less safe than fully tempered glass |

Introduction to Heat-Soaked and Heat-Strengthened Glass

Heat-soaked glass undergoes a rigorous testing process at high temperatures to eliminate the risk of spontaneous breakage caused by nickel sulfide inclusions, ensuring enhanced safety and reliability. Heat-strengthened glass is thermally treated to increase its strength to about twice that of annealed glass, providing improved resistance to wind loads and thermal stress without shattering into small fragments. Your choice between these types depends on the balance between safety testing and structural performance required for your project.

Manufacturing Processes Compared

Heat-soaked glass undergoes a thermal treatment process where it is heated to approximately 280degC to 320degC to induce the rupture of nickel sulfide inclusions, minimizing the risk of spontaneous breakage. Heat-strengthened glass, in contrast, is heated to around 620degC and then rapidly cooled to create compressive stress on the surface, doubling its strength compared to annealed glass but lacking the nickel sulfide testing benefit. Both processes enhance glass performance for architectural applications, with heat soaking targeting safety through impurity testing and heat strengthening focusing on mechanical durability.

Key Physical and Mechanical Properties

Heat-soaked glass undergoes a thermal treatment to reduce the risk of spontaneous breakage by eliminating nickel sulfide inclusions, resulting in improved stress distribution but maintaining similar strength to annealed glass. Heat-strengthened glass is heated and rapidly cooled, producing approximately twice the strength of annealed glass with enhanced impact resistance and thermal stability, but less than fully tempered glass. Both types exhibit different post-treatment residual stress profiles, with heat-strengthened glass offering higher mechanical performance for safety applications requiring moderate strength.

Differences in Strength and Durability

Heat-soaked glass undergoes a testing process to detect and eliminate nickel sulfide inclusions, preventing spontaneous breakage, while heat-strengthened glass is mechanically stronger, typically twice as strong as annealed glass, offering enhanced impact resistance. Heat-strengthened glass provides greater durability under thermal stress compared to heat-soaked glass, which mainly ensures safety by reducing breakage risk. Your choice between the two depends on whether you prioritize structural strength or the prevention of unexpected glass failure.

Thermal Shock Resistance: Which Performs Better?

Heat-soaked glass undergoes a specialized process that detects and reduces the risk of spontaneous breakage caused by nickel sulfide inclusions, improving its safety but not significantly enhancing thermal shock resistance. Heat-strengthened glass, subjected to partial tempering, offers approximately twice the strength of annealed glass and better withstands thermal stress, making it more resistant to thermal shock. Your choice should consider that heat-strengthened glass performs better in thermal shock resistance, ideal for applications exposed to rapid temperature changes.

Spontaneous Breakage Risks

Heat-soaked glass undergoes a specialized treatment to minimize the risk of spontaneous breakage caused by nickel sulfide inclusions, making it more reliable for applications where safety is critical. Heat-strengthened glass, while stronger than annealed glass and resistant to thermal stress, still retains a higher possibility of spontaneous breakage compared to heat-soaked glass. Your choice between these types should consider the importance of reducing breakage risks for enhanced safety in architectural or automotive glass installations.

Safety Applications and Best Uses

Heat-soaked glass undergoes a specific thermal process to reduce the risk of spontaneous breakage caused by nickel sulfide inclusions, making it ideal for safety-critical applications such as facades and overhead glazing where human protection is paramount. Heat-strengthened glass, retaining about twice the strength of annealed glass but without the anti-nickel sulfide treatment, suits structural uses that require improved load resistance but where breakage impact is less critical, like spandrels and balustrades. For best safety outcomes, heat-soaked glass is preferred in environments prone to thermal stress or where failure consequences are severe, while heat-strengthened glass offers a cost-effective solution in moderate safety-demand scenarios.

Cost Considerations and Economic Impact

Heat-soaked glass typically incurs higher upfront costs due to the additional testing process designed to reduce the risk of spontaneous breakage, increasing overall project expenses. Heat-strengthened glass offers a more economical alternative with enhanced strength compared to annealed glass but at a lower price point than fully tempered glass or heat-soaked variants. Choosing between these options significantly impacts budget allocation, balancing safety requirements and financial constraints in construction projects.

Industry Standards and Certifications

Heat-soaked glass undergoes rigorous testing to meet industry standards such as EN 14179, which ensures the detection of nickel sulfide inclusions that can cause spontaneous glass breakage. Heat-strengthened glass typically complies with ASTM C1048 standards, providing enhanced strength and safety without the extensive defect screening of heat-soaked glass. Your choice between these options should consider certifications relevant to your project's safety requirements and local building codes.

Choosing Between Heat-Soaked and Heat-Strengthened Glass

When choosing between heat-soaked and heat-strengthened glass, consider that heat-soaked glass undergoes an additional process to detect and remove nickel sulfide inclusions, reducing the risk of spontaneous breakage. Heat-strengthened glass offers approximately twice the strength of annealed glass but lacks the same breakage detection treatment, making it suitable for applications requiring enhanced durability without the need for heat soak testing. Your decision should prioritize safety requirements and the specific performance characteristics needed for your project.

heat-soaked glass vs heat-strengthened glass Infographic

libmatt.com

libmatt.com