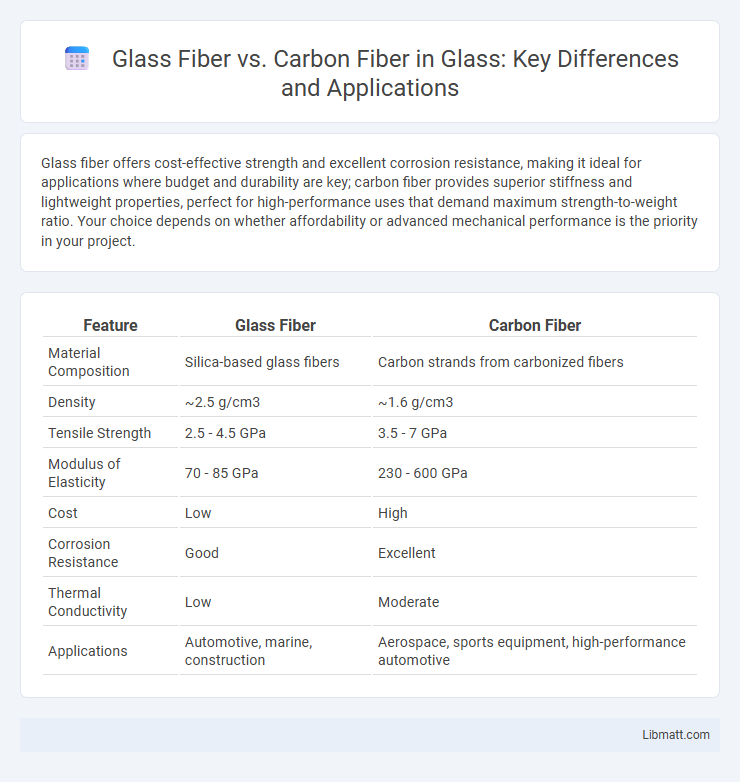

Glass fiber offers cost-effective strength and excellent corrosion resistance, making it ideal for applications where budget and durability are key; carbon fiber provides superior stiffness and lightweight properties, perfect for high-performance uses that demand maximum strength-to-weight ratio. Your choice depends on whether affordability or advanced mechanical performance is the priority in your project.

Table of Comparison

| Feature | Glass Fiber | Carbon Fiber |

|---|---|---|

| Material Composition | Silica-based glass fibers | Carbon strands from carbonized fibers |

| Density | ~2.5 g/cm3 | ~1.6 g/cm3 |

| Tensile Strength | 2.5 - 4.5 GPa | 3.5 - 7 GPa |

| Modulus of Elasticity | 70 - 85 GPa | 230 - 600 GPa |

| Cost | Low | High |

| Corrosion Resistance | Good | Excellent |

| Thermal Conductivity | Low | Moderate |

| Applications | Automotive, marine, construction | Aerospace, sports equipment, high-performance automotive |

Introduction to Glass Fiber and Carbon Fiber

Glass fiber consists of extremely fine fibers of glass woven into a fabric or formed into mats, widely used for its high tensile strength, lightweight nature, and cost-effectiveness in applications like construction and automotive industries. Carbon fiber, composed of thin strands of carbon atoms bonded together in a crystalline formation, offers superior strength-to-weight ratios, exceptional stiffness, and resistance to corrosion, making it ideal for aerospace, high-performance sports equipment, and advanced engineering projects. When choosing materials, understanding the distinct mechanical properties and cost considerations of glass fiber versus carbon fiber can help you optimize performance and budget for your specific application.

Composition and Manufacturing Processes

Glass fiber is composed primarily of silica-based glass, produced by melting raw materials like sand, limestone, and soda ash, then extruding them into fine fibers through a process called fiber drawing. Carbon fiber consists of thin strands of carbon atoms tightly bonded in a crystalline structure, created by heating polyacrylonitrile (PAN) or pitch fibers in a controlled environment through carbonization and graphitization processes. Manufacturing carbon fiber requires higher temperatures and more complex steps, resulting in stronger, lighter materials compared to the less expensive and more chemically resistant glass fiber.

Mechanical Properties Comparison

Carbon fiber offers superior mechanical properties compared to glass fiber, featuring higher tensile strength and stiffness, making it ideal for high-performance applications requiring lightweight and robust materials. Glass fiber provides good strength and flexibility but falls short in stiffness and fatigue resistance when compared to carbon fiber. Your choice between the two should consider the mechanical demands of your project, balancing cost and performance requirements.

Weight and Density Differences

Carbon fiber typically has a density of around 1.6 g/cm3, which is significantly lower than glass fiber's density of approximately 2.5 g/cm3. This difference in density makes carbon fiber much lighter, offering superior strength-to-weight ratios for high-performance applications in aerospace, automotive, and sporting goods industries. Weight reduction achieved with carbon fiber enhances fuel efficiency and structural performance, making it the preferred choice over glass fiber for weight-sensitive designs.

Cost and Affordability

Glass fiber offers significantly lower costs compared to carbon fiber, making it a more affordable option for large-scale manufacturing. Carbon fiber's high production expenses and raw material costs limit its use to applications demanding superior strength-to-weight ratios. Choosing glass fiber provides budget-friendly durability for industries like construction and automotive without the premium price associated with carbon composites.

Durability and Lifespan

Carbon fiber exhibits superior durability and lifespan compared to glass fiber due to its higher tensile strength and resistance to fatigue and environmental degradation. Glass fiber, while more cost-effective, is prone to stress corrosion and has a shorter service life under cyclic loading conditions. The enhanced longevity of carbon fiber composites makes them ideal for demanding applications in aerospace and automotive industries where extended durability is critical.

Applications Across Industries

Glass fiber finds extensive use in automotive manufacturing, marine vessels, and construction due to its cost-effectiveness and corrosion resistance, while carbon fiber is preferred in aerospace, high-performance sports equipment, and luxury automotive sectors for its superior strength-to-weight ratio and stiffness. In wind energy, glass fiber composites enhance turbine blade durability, whereas carbon fiber contributes to lightweight, high-efficiency rotor designs. The electronics industry utilizes both materials for lightweight, heat-resistant housings, but carbon fiber's electrical conductivity enables specialized applications like electromagnetic shielding.

Environmental Impact and Recycling

Glass fiber has a lower energy footprint during production compared to carbon fiber, making it somewhat more environmentally friendly. Recycling glass fiber remains challenging due to its composite nature, but it is more commonly processed into secondary materials than carbon fiber, which requires specialized and energy-intensive recycling methods. Your choice between the two should consider long-term environmental impact alongside performance needs, as carbon fiber's durability often extends product life and reduces waste.

Performance in Extreme Conditions

Carbon fiber exhibits superior performance in extreme conditions due to its high tensile strength, excellent thermal stability, and resistance to corrosion and fatigue, making it ideal for aerospace and high-performance automotive applications. Glass fiber, while more cost-effective and offering good resistance to heat and moisture, tends to degrade faster under prolonged exposure to high temperatures and harsh chemical environments. Your choice between glass fiber and carbon fiber should consider the specific environmental stresses and durability requirements of the application.

Choosing the Right Material: Key Considerations

Selecting between glass fiber and carbon fiber hinges on factors such as strength-to-weight ratio, cost, and application requirements. Carbon fiber offers superior tensile strength and stiffness with low weight, ideal for high-performance aerospace and automotive uses, but comes at a higher price. Glass fiber provides greater flexibility and impact resistance at a significantly lower cost, making it suitable for marine, construction, and general-purpose applications.

glass fiber vs carbon fiber Infographic

libmatt.com

libmatt.com