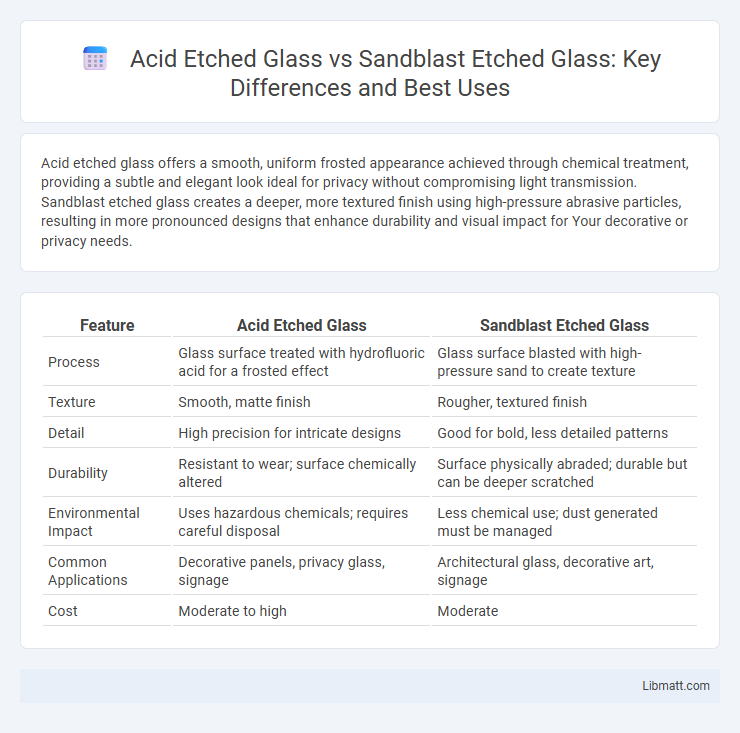

Acid etched glass offers a smooth, uniform frosted appearance achieved through chemical treatment, providing a subtle and elegant look ideal for privacy without compromising light transmission. Sandblast etched glass creates a deeper, more textured finish using high-pressure abrasive particles, resulting in more pronounced designs that enhance durability and visual impact for Your decorative or privacy needs.

Table of Comparison

| Feature | Acid Etched Glass | Sandblast Etched Glass |

|---|---|---|

| Process | Glass surface treated with hydrofluoric acid for a frosted effect | Glass surface blasted with high-pressure sand to create texture |

| Texture | Smooth, matte finish | Rougher, textured finish |

| Detail | High precision for intricate designs | Good for bold, less detailed patterns |

| Durability | Resistant to wear; surface chemically altered | Surface physically abraded; durable but can be deeper scratched |

| Environmental Impact | Uses hazardous chemicals; requires careful disposal | Less chemical use; dust generated must be managed |

| Common Applications | Decorative panels, privacy glass, signage | Architectural glass, decorative art, signage |

| Cost | Moderate to high | Moderate |

Introduction to Etched Glass Techniques

Acid etched glass involves using hydrofluoric acid to create a permanent, smooth, and translucent surface by chemically reacting with the glass, offering precise and consistent designs. Sandblast etched glass relies on high-pressure abrasive materials to physically erode the glass surface, producing a textured, frosted appearance with variable depth and detail. Both techniques enhance glass aesthetics and privacy, but acid etching delivers finer detail while sandblasting provides a more tactile, rugged finish.

What is Acid Etched Glass?

Acid etched glass is created by applying hydrofluoric acid to the surface, producing a permanent frosted, matte finish that diffuses light and enhances privacy. This process allows for precise, intricate designs with a smooth texture that resists fingerprints and smudges. Your choice of acid etched glass offers durability and clarity ideal for decorative and functional applications in both residential and commercial settings.

What is Sandblast Etched Glass?

Sandblast etched glass is created by propelling fine grains of abrasive material at high velocity to carve intricate designs or textures onto the glass surface, producing a frosted, opaque appearance. This technique allows for greater precision and varied depth compared to acid etched glass, which uses chemical treatments to achieve a more uniform matte finish. You can choose sandblast etched glass for detailed artwork or logos due to its versatility and sharp design capabilities.

Key Differences Between Acid Etched and Sandblast Etched Glass

Acid etched glass achieves a smooth, frosted surface by applying hydrofluoric acid, offering consistent texture and subtle translucency, while sandblast etched glass uses high-pressure abrasive particles to create deeper, more pronounced designs with a tactile finish. Acid etching is ideal for delicate patterns and uniform matte effects, whereas sandblasting provides greater versatility for intricate, bold art and variable depths. Your choice depends on desired finish, design complexity, and maintenance, as acid etched glass is more resistant to scratches and easier to clean compared to sandblast etching.

Visual Appearance: Acid Etch vs Sandblast Etch

Acid etched glass features a smooth, frosted surface with a consistent matte finish that diffuses light evenly, creating a soft, elegant look. Sandblast etched glass offers a slightly rougher texture with deeper grooves, resulting in a more pronounced and opaque design that enhances contrast and visibility. Both techniques provide privacy, but acid etching is preferred for subtle, refined aesthetics, while sandblasting delivers bold, tactile patterns ideal for architectural and decorative applications.

Durability and Maintenance Comparison

Acid etched glass features a smooth, matte surface created by chemical treatment, making it resistant to scratches and easy to clean with standard glass cleaners, ensuring long-lasting durability. Sandblast etched glass has a textured, frosted appearance achieved through high-pressure abrasive blasting, which can be more prone to surface scratches and requires gentle cleaning to prevent damage. Your choice between acid etched and sandblast etched glass impacts maintenance needs, with acid etched glass generally offering greater durability and simpler upkeep.

Cost Factors: Acid Etched vs Sandblast Etched Glass

Acid etched glass typically incurs higher costs due to the use of hazardous chemicals and specialized handling requirements, increasing both material and labor expenses. Sandblast etched glass involves lower material costs but may require more time and precision in the blasting process, impacting overall labor costs. Budget considerations should factor in the complexity of design, surface area, and production volume, as these influence the cost efficiency of acid etching versus sandblasting techniques.

Applications and Ideal Uses

Acid etched glass is commonly used in architectural applications such as office partitions, shower enclosures, and decorative panels due to its smooth, uniform frosted appearance and high durability. Sandblast etched glass is ideal for intricate designs, signage, and artistic patterns because the abrasive process allows for deep, detailed textures and variable opacity. Both methods enhance privacy while maintaining light transmission, with acid etching preferred for large surface areas and sandblasting suited to customized, precise etching work.

Environmental and Safety Considerations

Acid etched glass uses strong chemicals that require careful handling and proper ventilation to ensure safety, while sandblast etched glass involves blasting abrasive materials that can produce fine dust, necessitating protective equipment and dust control measures. Both methods have environmental impacts, but sandblasting typically generates less hazardous waste compared to the chemical runoff from acid etching. Choosing your preferred technique depends on balancing these environmental and safety considerations with the specific project requirements.

Which Etched Glass Technique is Right for Your Project?

Choosing between acid etched glass and sandblast etched glass depends on your project's detail and texture requirements. Acid etching offers a softer, more uniform finish ideal for elegant designs and privacy, while sandblasting provides sharper, deeper textures suited for intricate patterns and durability. Your decision should consider the desired aesthetic, budget, and glass thickness to ensure the perfect fit for your project.

acid etched glass vs sandblast etched glass Infographic

libmatt.com

libmatt.com