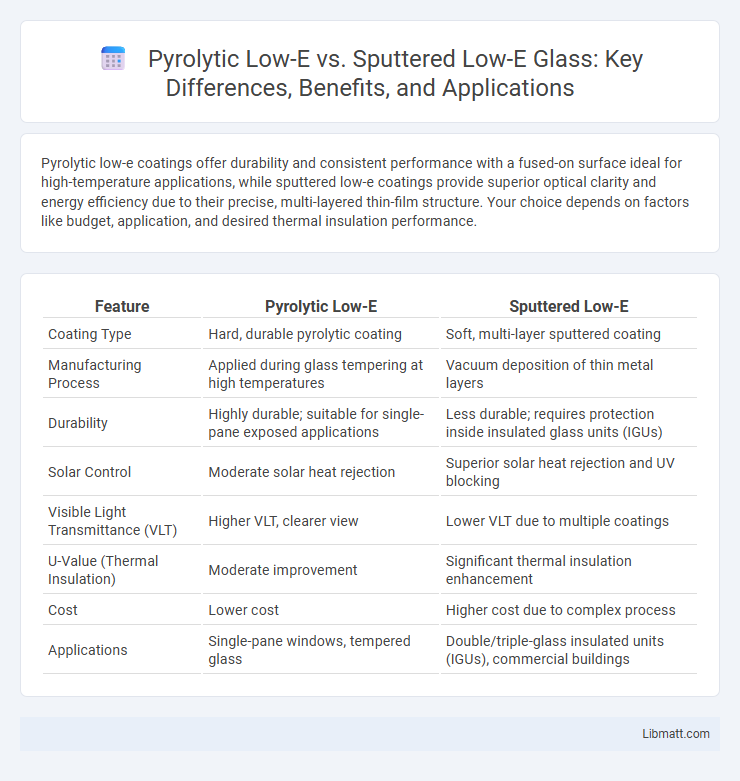

Pyrolytic low-e coatings offer durability and consistent performance with a fused-on surface ideal for high-temperature applications, while sputtered low-e coatings provide superior optical clarity and energy efficiency due to their precise, multi-layered thin-film structure. Your choice depends on factors like budget, application, and desired thermal insulation performance.

Table of Comparison

| Feature | Pyrolytic Low-E | Sputtered Low-E |

|---|---|---|

| Coating Type | Hard, durable pyrolytic coating | Soft, multi-layer sputtered coating |

| Manufacturing Process | Applied during glass tempering at high temperatures | Vacuum deposition of thin metal layers |

| Durability | Highly durable; suitable for single-pane exposed applications | Less durable; requires protection inside insulated glass units (IGUs) |

| Solar Control | Moderate solar heat rejection | Superior solar heat rejection and UV blocking |

| Visible Light Transmittance (VLT) | Higher VLT, clearer view | Lower VLT due to multiple coatings |

| U-Value (Thermal Insulation) | Moderate improvement | Significant thermal insulation enhancement |

| Cost | Lower cost | Higher cost due to complex process |

| Applications | Single-pane windows, tempered glass | Double/triple-glass insulated units (IGUs), commercial buildings |

Introduction to Low-E Glass Technologies

Pyrolytic low-e glass features a durable, hard coating applied during the glass manufacturing process, providing moderate solar control and thermal insulation ideal for tempering and laminating. Sputtered low-e glass utilizes a vacuum deposition technique to apply multiple ultra-thin metallic layers offering superior thermal performance and solar heat control, often used in high-performance architectural applications. Both technologies enhance energy efficiency by reflecting infrared heat while allowing visible light transmission, but sputtered coatings generally deliver higher emissivity reduction and better long-term durability under sealed glass unit conditions.

What is Pyrolytic Low-E Glass?

Pyrolytic low-e glass is a type of energy-efficient glass coated with a durable, thin layer of metal oxide applied during the manufacturing process at high temperatures. This coating enhances thermal insulation by reflecting infrared heat while allowing visible light to pass through, making it ideal for windows in both residential and commercial buildings. Compared to sputtered low-e glass, pyrolytic coatings are more robust and can be processed or tempered after coating without damaging the low-e layer.

What is Sputtered Low-E Glass?

Sputtered Low-E glass is a type of low-emissivity glass created by applying multiple ultra-thin metallic coatings to the glass surface in a vacuum chamber, resulting in enhanced thermal insulation and solar control properties. Unlike pyrolytic Low-E, which bonds the coating during the glass manufacturing process, sputtered coatings provide superior durability, lower emissivity values, and better performance in insulating glazing units. This technology offers improved energy efficiency by significantly reducing heat transfer and controlling visible light transmission while maintaining high optical clarity.

Key Differences Between Pyrolytic and Sputtered Low-E

Pyrolytic low-e coatings are applied during the glass manufacturing process at high temperatures, creating a durable, hard coating bonded strongly to the glass surface, ideal for single-pane applications. Sputtered low-e coatings are deposited in a vacuum chamber at lower temperatures, producing multiple thin metallic layers that offer superior thermal performance and are often used in double or triple-glazed insulating glass units. The primary differences lie in durability, thermal efficiency, and application methods, with pyrolytic coatings being more robust but less effective at reducing heat transfer compared to the more delicate but higher-performing sputtered coatings.

Energy Efficiency Comparison

Pyrolytic low-e coatings offer moderate energy efficiency by reducing heat transfer through solar control and thermal insulation, typically used in double-glazed windows for residential applications. Sputtered low-e coatings provide superior energy performance with multiple thin layers that enhance thermal insulation and minimize infrared heat transfer, making them ideal for extreme climates or high-performance buildings. Your choice between pyrolytic and sputtered low-e depends on the balance between cost and the level of energy savings required for your space.

Durability and Maintenance

Pyrolytic low-e coatings offer superior durability due to their hard, baked-on surface, making them resistant to scratches and suitable for single-pane or insulating glass units without special handling. Sputtered low-e coatings, while more efficient in thermal performance, are delicate and require careful handling during manufacturing and installation to prevent damage. Your choice should consider maintenance needs, as pyrolytic low-e windows typically demand less upkeep and provide long-lasting protection against wear.

Aesthetic and Visual Clarity

Pyrolytic low-e coatings typically offer a uniform surface with higher durability but may exhibit slightly lower optical clarity compared to sputtered low-e coatings, which provide superior visual clarity and color neutrality due to their precise, multi-layered deposition process. Sputtered low-e coatings reduce reflectance and enhance light transmission, resulting in clearer views and more vibrant, true-to-life colors, making them ideal for premium architectural applications. Pyrolytic coatings, while durable and easier to handle, may produce a subtle haze or tint, slightly impacting aesthetic appeal in high-clarity glazing needs.

Cost Considerations

Pyrolytic low-e coatings are generally more cost-effective due to their durability during manufacturing and simpler application process, making them ideal for standard window production. Sputtered low-e coatings, while offering superior thermal performance and clarity, come with higher production costs that impact the overall price of your windows. Choosing between pyrolytic and sputtered low-e depends on balancing upfront expense with long-term energy savings and performance requirements.

Applications and Suitability

Pyrolytic low-e coatings are ideal for residential windows and can be tempered or laminated, offering durability and cost-effectiveness in single-pane or insulating glass units. Sputtered low-e coatings provide superior thermal performance and solar control, making them suitable for high-performance commercial buildings and applications requiring enhanced energy efficiency and visible light transmission. Choosing between pyrolytic and sputtered low-e depends on specific project needs, such as budget, environmental conditions, and desired thermal insulation levels.

Choosing the Right Low-E Glass for Your Needs

Pyrolytic low-e glass offers durable, hard coatings applied during manufacturing, making it ideal for single-pane or storm windows where longevity and ease of handling matter. Sputtered low-e glass features multiple, thin metal oxide layers deposited in a vacuum, delivering superior thermal performance and UV protection, perfect for double or triple-pane insulated glass units in energy-efficient buildings. Your choice depends on balancing cost, durability, and performance requirements to optimize energy savings and comfort.

pyrolytic low-e vs sputtered low-e Infographic

libmatt.com

libmatt.com