Laminated glass offers enhanced safety by holding together when shattered due to its interlayer, making it ideal for impact resistance and sound insulation. Toughened glass, on the other hand, is heat-treated to be stronger than regular glass and breaks into small, blunt pieces, providing durability and safety for high-stress environments.

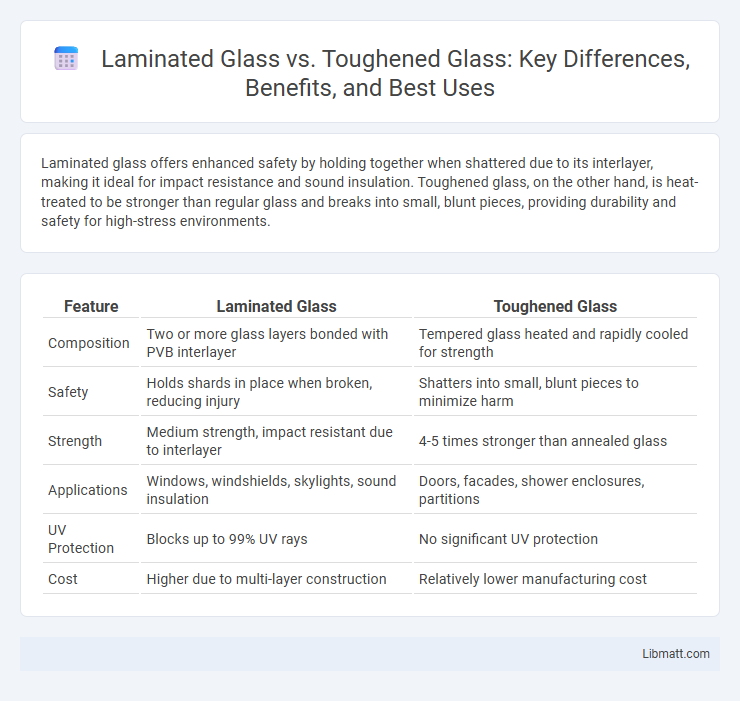

Table of Comparison

| Feature | Laminated Glass | Toughened Glass |

|---|---|---|

| Composition | Two or more glass layers bonded with PVB interlayer | Tempered glass heated and rapidly cooled for strength |

| Safety | Holds shards in place when broken, reducing injury | Shatters into small, blunt pieces to minimize harm |

| Strength | Medium strength, impact resistant due to interlayer | 4-5 times stronger than annealed glass |

| Applications | Windows, windshields, skylights, sound insulation | Doors, facades, shower enclosures, partitions |

| UV Protection | Blocks up to 99% UV rays | No significant UV protection |

| Cost | Higher due to multi-layer construction | Relatively lower manufacturing cost |

Introduction to Laminated and Toughened Glass

Laminated glass consists of two or more layers of glass bonded with an interlayer, providing enhanced safety by holding shards together upon impact. Toughened glass, also known as tempered glass, is heat-treated to increase its strength and shatter into small, blunt pieces instead of sharp shards. Your choice between laminated and toughened glass depends on safety requirements, strength, and application needs such as windows, doors, or facades.

What is Laminated Glass?

Laminated glass consists of two or more glass layers bonded together with a durable interlayer, typically made of polyvinyl butyral (PVB), which enhances safety by holding the glass fragments in place if shattered. Its design offers superior impact resistance and sound insulation compared to regular glass, making it ideal for automotive windshields and architectural applications where safety and security are priorities. You can rely on laminated glass to provide protection against breakage while maintaining clarity and strength in your living or working spaces.

What is Toughened Glass?

Toughened glass, also known as tempered glass, is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared to normal glass. It is designed to shatter into small, blunt pieces rather than sharp shards, reducing the risk of injury upon breakage. Commonly used in automotive windows, shower doors, and building facades, toughened glass offers enhanced durability and impact resistance.

Key Manufacturing Differences

Laminated glass is produced by bonding two or more glass layers with an interlayer of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA) under heat and pressure, ensuring it holds together when shattered. Toughened glass, also known as tempered glass, undergoes a rapid cooling process after being heated to around 620degC, creating internal compressive stresses that increase its strength and cause it to break into small, blunt pieces. Understanding these key manufacturing differences helps you select the right glass type for safety, durability, and application-specific needs.

Strength and Durability Comparison

Laminated glass consists of two or more layers of glass bonded with an interlayer, providing enhanced impact resistance and preventing shattering into sharp pieces, making it ideal for safety applications. Toughened glass, also known as tempered glass, undergoes heat treatment to increase its strength by up to five times compared to annealed glass, and it breaks into small, blunt granules to reduce injury risk. Your choice between laminated and toughened glass should consider the specific strength and durability requirements of your project, as laminated glass excels in impact retention while toughened glass offers superior resistance to thermal stress.

Safety and Security Features

Laminated glass consists of two or more layers of glass bonded with an interlayer, providing enhanced safety by preventing shattering upon impact and retaining glass fragments, significantly reducing injury risk. Toughened glass is heat-treated to increase strength and, upon breakage, shatters into small blunt pieces, minimizing severe cuts but not preventing penetration or intrusion. Laminated glass offers superior security features due to its ability to resist forced entry and acts as a barrier against impacts, making it ideal for areas requiring heightened protection.

Acoustic and Thermal Insulation Properties

Laminated glass offers superior acoustic insulation due to its interlayer, which effectively dampens sound transmission, making it ideal for noisy environments. Toughened glass provides excellent thermal resistance and is designed to withstand high temperatures, but it lacks the soundproofing benefits of laminated glass. Your choice should depend on whether noise reduction or heat resistance is the primary requirement for your space.

Applications in Modern Architecture

Laminated glass is widely used in modern architecture for safety and sound insulation in facades, skylights, and balustrades due to its ability to hold shards together upon impact. Toughened glass is preferred for high-strength applications like structural doors, windows, and curtain walls, offering enhanced resistance to thermal stress and impact. Both types complement each other by balancing safety, durability, and aesthetic appeal in contemporary building designs.

Cost and Maintenance Considerations

Laminated glass generally costs more upfront than toughened glass due to its complex manufacturing process involving multiple layers and interlayers for added safety and sound insulation. Maintenance for laminated glass often requires careful cleaning to avoid damage to the interlayer, whereas toughened glass is easier to maintain thanks to its single-pane structure and greater resistance to scratches and impacts. Your choice between the two should weigh the higher initial expense of laminated glass against potentially lower long-term maintenance costs associated with toughened glass.

Choosing the Right Glass for Your Project

Laminated glass offers superior safety and sound insulation by bonding two glass layers with a durable interlayer, making it ideal for projects requiring impact resistance and noise reduction. Toughened glass, known for its high strength and shatter-resistant properties, is best suited for designs that prioritize durability and thermal resistance. Understanding these features helps you select the perfect glass type to meet your project's specific safety, performance, and aesthetic needs.

Laminated glass vs toughened glass Infographic

libmatt.com

libmatt.com