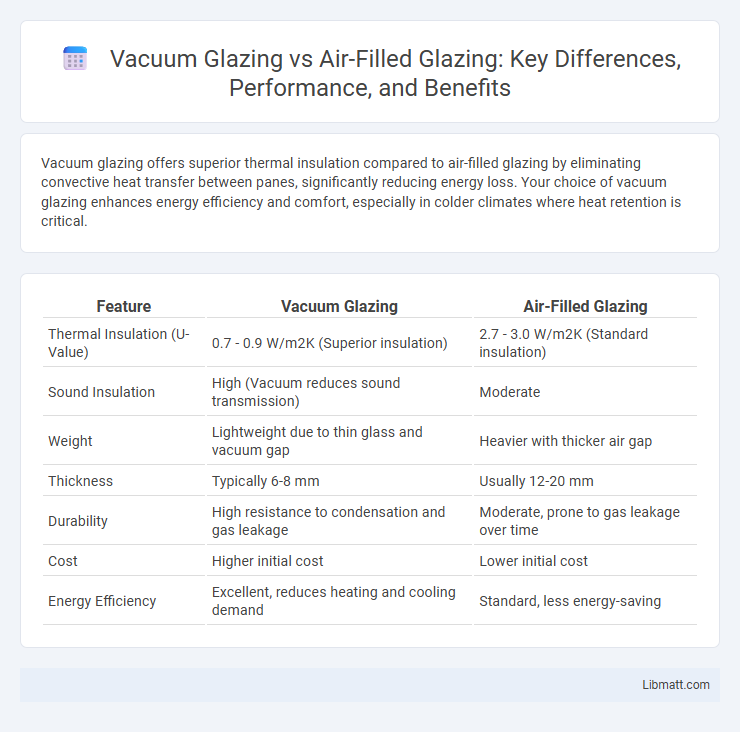

Vacuum glazing offers superior thermal insulation compared to air-filled glazing by eliminating convective heat transfer between panes, significantly reducing energy loss. Your choice of vacuum glazing enhances energy efficiency and comfort, especially in colder climates where heat retention is critical.

Table of Comparison

| Feature | Vacuum Glazing | Air-Filled Glazing |

|---|---|---|

| Thermal Insulation (U-Value) | 0.7 - 0.9 W/m2K (Superior insulation) | 2.7 - 3.0 W/m2K (Standard insulation) |

| Sound Insulation | High (Vacuum reduces sound transmission) | Moderate |

| Weight | Lightweight due to thin glass and vacuum gap | Heavier with thicker air gap |

| Thickness | Typically 6-8 mm | Usually 12-20 mm |

| Durability | High resistance to condensation and gas leakage | Moderate, prone to gas leakage over time |

| Cost | Higher initial cost | Lower initial cost |

| Energy Efficiency | Excellent, reduces heating and cooling demand | Standard, less energy-saving |

Introduction to Vacuum Glazing and Air-Filled Glazing

Vacuum glazing consists of two or more glass panes separated by a vacuum layer that significantly reduces heat transfer by conduction and convection, enhancing thermal insulation compared to traditional air-filled glazing. Air-filled glazing uses trapped air between glass panes as an insulating layer, which provides moderate thermal resistance but is less effective than vacuum glazing in minimizing heat loss. The vacuum gap in vacuum glazing offers superior energy efficiency and thinner profile options, making it a premium choice for energy-conscious building designs.

How Vacuum Glazing Works

Vacuum glazing consists of two glass panes separated by a narrow vacuum space that eliminates conductive and convective heat transfer, significantly improving thermal insulation compared to air-filled glazing. Tiny support pillars maintain the gap between the panes, preventing collapse while preserving the vacuum. This technology reduces heat loss and enhances energy efficiency in windows, making it superior to traditional air-filled double glazing.

Fundamentals of Air-Filled Glazing

Air-filled glazing consists of two or more glass panes separated by a sealed air space that provides insulation by reducing heat transfer through conduction and convection. The air trapped between the panes acts as a thermal barrier, though its insulating performance is limited by air's relatively high thermal conductivity compared to vacuum environments. This fundamental principle of air-filled glazing impacts its overall energy efficiency compared to vacuum glazing, which uses a near-vacuum space to minimize heat loss more effectively.

Thermal Performance Comparison

Vacuum glazing offers superior thermal insulation with U-values as low as 0.5 W/m2K compared to air-filled glazing, which typically ranges from 1.2 to 2.0 W/m2K. The vacuum layer eliminates convective heat transfer, significantly reducing energy loss and improving overall energy efficiency in buildings. This enhanced thermal performance makes vacuum glazing a preferred choice for high-performance windows in cold climates or passive house designs.

Energy Efficiency: Vacuum vs Air-Filled Glazing

Vacuum glazing significantly outperforms air-filled glazing in energy efficiency due to its minimal heat transfer properties, achieving U-values as low as 0.5 W/m2K compared to 1.2-2.8 W/m2K for conventional air-filled units. The vacuum gap eliminates conductive and convective heat losses, substantially reducing thermal bridging and improving insulation performance. This advanced technology enhances building energy conservation, lowers heating and cooling costs, and contributes to achieving stricter energy codes and sustainability goals.

Acoustic Insulation Properties

Vacuum glazing offers superior acoustic insulation properties compared to air-filled glazing due to the near-complete elimination of air molecules between panes, reducing sound transmission significantly. This technology effectively dampens external noise, making it ideal for urban environments or noisy locations. Your choice of vacuum glazing can enhance indoor comfort by minimizing sound pollution more efficiently than traditional air-filled alternatives.

Durability and Longevity

Vacuum glazing offers superior durability and longevity compared to air-filled glazing due to its resistance to thermal stress and minimal gas leakage over time. The double-pane vacuum insulation minimizes condensation and maintains insulating properties for decades, often exceeding 30 years with proper seals. Air-filled glazing typically experiences reduced performance and potential seal failures within 10-15 years, leading to decreased energy efficiency and increased maintenance costs.

Installation and Maintenance Considerations

Vacuum glazing requires specialized installation techniques to maintain the vacuum seal and prevent air infiltration, making professional expertise essential. Air-filled glazing is easier to install with standard glazing methods but may need periodic inspection for seal integrity to avoid condensation issues. Your choice impacts long-term maintenance, with vacuum glazing offering superior energy efficiency but demanding careful handling to preserve its vacuum environment.

Cost Analysis: Initial and Lifetime Expenses

Vacuum glazing generally has higher initial costs due to advanced manufacturing processes and materials compared to air-filled glazing, which remains more affordable upfront. Over the lifetime, vacuum glazing offers significant energy savings and improved thermal insulation, reducing heating and cooling expenses more effectively than air-filled glazing. Maintenance and replacement costs for vacuum glazing can be lower due to its durability and resistance to condensation, potentially offsetting its initial investment over time.

Choosing the Right Glazing for Your Project

Vacuum glazing offers superior thermal insulation with a U-value as low as 0.7 W/m2K, reducing heat loss significantly compared to traditional air-filled glazing, which typically has a U-value around 1.2-1.4 W/m2K. Its slim profile and enhanced energy efficiency make it ideal for projects with space constraints or high-performance requirements, while air-filled glazing remains a cost-effective option for standard insulation needs. Selecting the right glazing depends on balancing budget, thermal efficiency, space savings, and the specific energy performance goals of your project.

Vacuum glazing vs air-filled glazing Infographic

libmatt.com

libmatt.com