Single strength glass typically measures about 3mm thick and is suitable for standard windows, offering basic insulation and durability. Double strength glass, around 6mm thick, provides enhanced strength and improved insulation, making it ideal for areas requiring better security and energy efficiency.

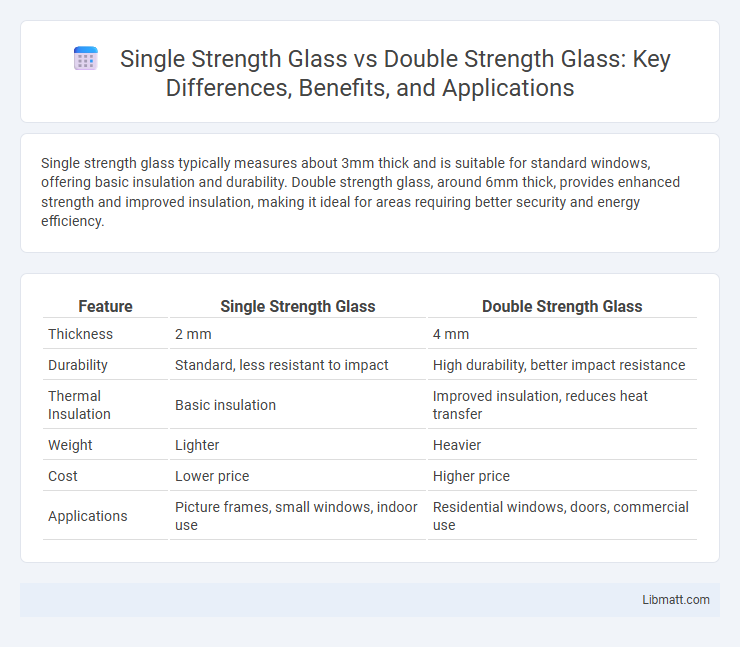

Table of Comparison

| Feature | Single Strength Glass | Double Strength Glass |

|---|---|---|

| Thickness | 2 mm | 4 mm |

| Durability | Standard, less resistant to impact | High durability, better impact resistance |

| Thermal Insulation | Basic insulation | Improved insulation, reduces heat transfer |

| Weight | Lighter | Heavier |

| Cost | Lower price | Higher price |

| Applications | Picture frames, small windows, indoor use | Residential windows, doors, commercial use |

Introduction to Single Strength Glass and Double Strength Glass

Single strength glass typically measures around 3mm thick and is commonly used in residential windows, offering basic insulation and soundproofing. Double strength glass is roughly 6mm thick, providing enhanced durability, better thermal insulation, and improved noise reduction for your windows. Choosing between single and double strength glass depends on your specific needs for energy efficiency and protection.

Key Differences Between Single and Double Strength Glass

Single strength glass typically measures around 2mm in thickness, offering basic protection and clarity ideal for small windows or picture frames. Double strength glass is thicker, usually about 3mm, providing enhanced durability and better resistance to impacts and heat, making it suitable for larger windows or areas requiring increased security. You can choose between these types based on the balance needed between cost, strength, and insulation for your specific application.

How Single Strength Glass is Manufactured

Single strength glass is manufactured by melting raw materials such as silica sand, soda ash, and limestone at high temperatures, followed by controlled cooling to achieve a uniform thickness of approximately 2.3mm. The process includes floating the molten glass on a bed of molten tin to create a smooth, flat surface, known as the float glass method. Quality control measures ensure consistent thickness and clarity, optimizing single strength glass for window panes and picture frames.

The Manufacturing Process of Double Strength Glass

Double strength glass is produced by melting raw materials at high temperatures and pouring the molten glass onto a flat surface to cool uniformly, resulting in a thicker and stronger pane compared to single strength glass. The thickness typically measures about 3/32 inch, achieved by controlled cooling and annealing to enhance structural integrity and reduce internal stresses. This manufacturing process allows double strength glass to better withstand impacts and thermal variations, making it suitable for applications requiring increased durability.

Durability: Single Strength vs Double Strength Glass

Single strength glass typically measures about 2mm in thickness and offers basic durability suitable for small windows and interior applications. Double strength glass is approximately 3mm thick, providing enhanced resistance to impacts and greater durability, making it ideal for larger windows and exterior use. Choosing double strength glass for Your project ensures better protection against breakage and longer-lasting strength in demanding environments.

Safety Considerations for Both Glass Types

Single strength glass typically offers greater safety by shattering into smaller, less harmful pieces upon impact, reducing the risk of injury compared to the thicker double strength glass that can break into larger, more dangerous shards. Double strength glass provides enhanced durability and resistance to impact but requires additional safety measures like tempered or laminated treatments to mitigate injury hazards. Choosing between single and double strength glass depends on balancing safety priorities with structural requirements and application-specific risks.

Energy Efficiency and Insulation Comparisons

Single strength glass offers basic insulation but lacks the advanced energy efficiency found in double strength glass, which provides enhanced thermal resistance due to its increased thickness. Double strength glass reduces heat transfer more effectively, helping maintain your indoor temperature and lowering energy costs. This improved insulation makes double strength glass a more sustainable choice for energy-efficient windows.

Cost Analysis: Single Strength vs Double Strength Glass

Single strength glass typically costs less per square foot compared to double strength glass due to its thinner composition and lower material usage. Double strength glass, being thicker and more durable, commands a higher price but offers enhanced impact resistance and longer lifespan, potentially reducing replacement costs over time. When considering overall investment, single strength glass suits budget-sensitive projects with minimal durability demands, while double strength glass justifies its higher upfront cost in applications requiring greater strength and longevity.

Ideal Applications for Single and Double Strength Glass

Single strength glass, typically 1/8 inch thick, is ideal for interior windows, picture frames, and small decorative items where durability is less critical. Double strength glass, measuring about 3/16 inch thick, suits exterior windows, commercial storefronts, and doors requiring enhanced durability and better insulation. Choosing between single and double strength glass depends on factors like location exposure, safety requirements, and thermal performance needs.

Choosing the Right Glass: Factors to Consider

Single strength glass measures approximately 2.3mm thick and is suitable for standard window applications, providing adequate clarity and insulation. Double strength glass, around 3.2mm thick, offers enhanced durability, better noise reduction, and improved thermal insulation, making it ideal for exterior windows in high-traffic or harsh weather areas. When choosing the right glass, consider your window frame compatibility, climate conditions, and energy efficiency needs to ensure the best performance for your space.

Single strength glass vs double strength glass Infographic

libmatt.com

libmatt.com