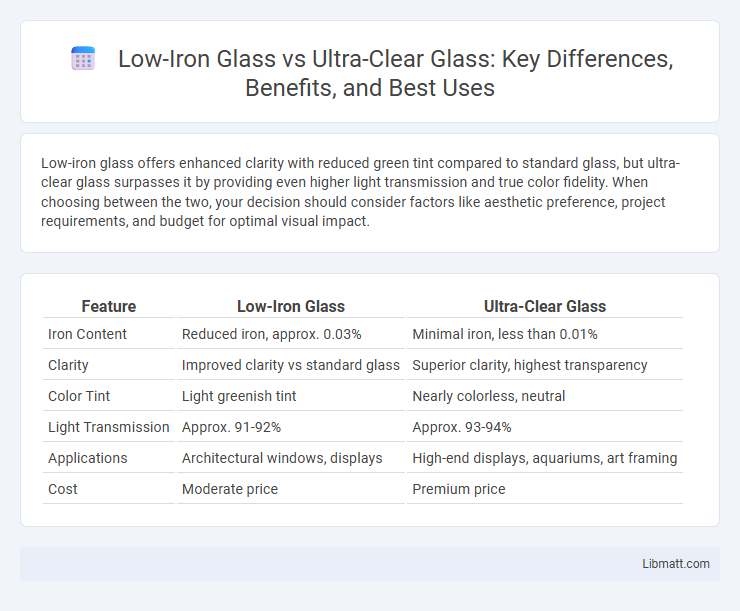

Low-iron glass offers enhanced clarity with reduced green tint compared to standard glass, but ultra-clear glass surpasses it by providing even higher light transmission and true color fidelity. When choosing between the two, your decision should consider factors like aesthetic preference, project requirements, and budget for optimal visual impact.

Table of Comparison

| Feature | Low-Iron Glass | Ultra-Clear Glass |

|---|---|---|

| Iron Content | Reduced iron, approx. 0.03% | Minimal iron, less than 0.01% |

| Clarity | Improved clarity vs standard glass | Superior clarity, highest transparency |

| Color Tint | Light greenish tint | Nearly colorless, neutral |

| Light Transmission | Approx. 91-92% | Approx. 93-94% |

| Applications | Architectural windows, displays | High-end displays, aquariums, art framing |

| Cost | Moderate price | Premium price |

Introduction to Low-Iron Glass and Ultra-Clear Glass

Low-iron glass contains reduced iron content compared to standard glass, resulting in improved clarity and transparency with a slight greenish tint still present. Ultra-clear glass offers even higher purity with minimal iron, delivering superior optical properties and nearly invisible edges, making it ideal for high-end displays and architectural applications. When choosing between the two, your decision should consider the level of clarity required and budget constraints for the project.

Composition Differences: What Sets Them Apart

Low-iron glass contains a higher amount of iron oxide, resulting in a slight green tint that affects its clarity, while ultra-clear glass is specifically manufactured with minimal iron content to achieve exceptional transparency and color neutrality. The reduced iron in ultra-clear glass enhances light transmission, making it ideal for applications requiring true color visibility, such as display cases, aquariums, and high-end architectural projects. Your choice between these two types should consider the importance of visual purity and the level of light distortion acceptable for your needs.

Manufacturing Processes Compared

Low-iron glass undergoes a refining process that reduces iron content to minimize the greenish tint typical of standard glass, resulting in improved clarity while maintaining cost-effectiveness. Ultra-clear glass, also known as extra-clear or low-iron float glass, involves a more advanced manufacturing process with higher purity raw materials and stricter control over contaminants, yielding superior light transmission and color neutrality. These differences in manufacturing impact the optical performance and applications, with ultra-clear glass preferred for premium architectural, display, and solar energy uses due to its exceptional transparency and color fidelity.

Optical Clarity and Light Transmission

Low-iron glass offers higher optical clarity and superior light transmission compared to standard glass due to its reduced iron content, which minimizes the greenish tint commonly seen in regular glass. Ultra-clear glass, also known as extra-clear or low-iron glass, typically transmits up to 91-92% of visible light, making it ideal for applications requiring maximum transparency and color fidelity. The enhanced clarity and brightness of ultra-clear glass make it a preferred choice for high-end displays, showcases, and architectural glazing where true color representation and minimal distortion are critical.

Color Characteristics and Visual Appeal

Low-iron glass exhibits a slight greenish tint due to its iron content, which can subtly alter the color perception of objects viewed through it and affect overall clarity. Ultra-clear glass contains significantly reduced iron levels, offering a neutral and more transparent appearance that enhances true-to-life color rendition and visual sharpness. The superior optical clarity of ultra-clear glass makes it the preferred choice for applications where color accuracy and enhanced light transmission are critical.

Strength and Durability Comparison

Low-iron glass exhibits high durability and impact resistance, making it suitable for structural applications where strength is critical. Ultra-clear glass, while offering superior clarity due to its reduced iron content, generally has comparable strength but may require additional treatments like tempering to match the durability of standard low-iron glass. Both types can be engineered for enhanced toughness, but low-iron glass often excels in applications demanding robust mechanical performance.

Common Applications of Each Glass Type

Low-iron glass is commonly used in architectural projects where enhanced clarity and natural color rendition are important, such as storefronts, facades, and solar panels. Ultra-clear glass, characterized by its higher transparency and minimal green tint, is preferred in high-end display cases, museum glazing, and aquariums where true color visibility and visual purity are critical. Both glass types serve specialized purposes in construction and design, with ultra-clear glass offering superior optical performance for premium applications.

Cost Analysis: Low-Iron vs Ultra-Clear Glass

Low-iron glass typically costs 15-30% less than ultra-clear glass due to lower purity levels and iron content, making it a budget-friendly option for standard window and display applications. Ultra-clear glass offers superior clarity and color neutrality with iron content below 0.03%, resulting in higher manufacturing costs and a price premium justified for high-end retail, museums, or architectural projects demanding exceptional visual quality. Your choice between low-iron and ultra-clear glass should balance cost constraints against the need for optical performance and aesthetic precision.

Environmental Impact and Sustainability

Low-iron glass offers lower environmental impact by utilizing fewer additives and consuming less energy during production compared to ultra-clear glass, which requires higher purity and more intensive refining processes. Ultra-clear glass provides superior clarity and light transmission, enhancing energy efficiency in buildings by maximizing natural light and reducing artificial lighting needs. You can contribute to sustainability efforts by selecting glass types based on project requirements and balancing clarity with environmental considerations.

Choosing the Right Glass for Your Project

Low-iron glass offers enhanced clarity with reduced green tint, making it ideal for architectural projects where natural light and color accuracy are crucial. Ultra-clear glass provides superior transparency and minimal distortion, perfect for display cases and high-end windows requiring exceptional visual performance. Evaluate your project's lighting, aesthetic requirements, and budget to determine whether low-iron glass or ultra-clear glass best meets Your needs.

Low-iron glass vs ultra-clear glass Infographic

libmatt.com

libmatt.com